In this article

Food safe seals: examples, standards, tips

Choosing the correct o-ring is of vital importance. When the o-rings are not food-grade, you are putting the health of your consumers at risk. Find out which seal is suitable for your application and learn how to select the right food-grade o-ring.

Types of seals

O-ring

An o-ring is easy to make in a variety of shapes and sizes, making it widely applicable and relatively inexpensive. We offer a wide range of o-rings for specific applications and industries, in different types, sizes and price ranges.

Milk gasket

The milk gasket is specially designed for sealing screw couplings within the food industry. As the name suggests, milk gaskets are widely used in dairy plants.

Tri-clamp seal

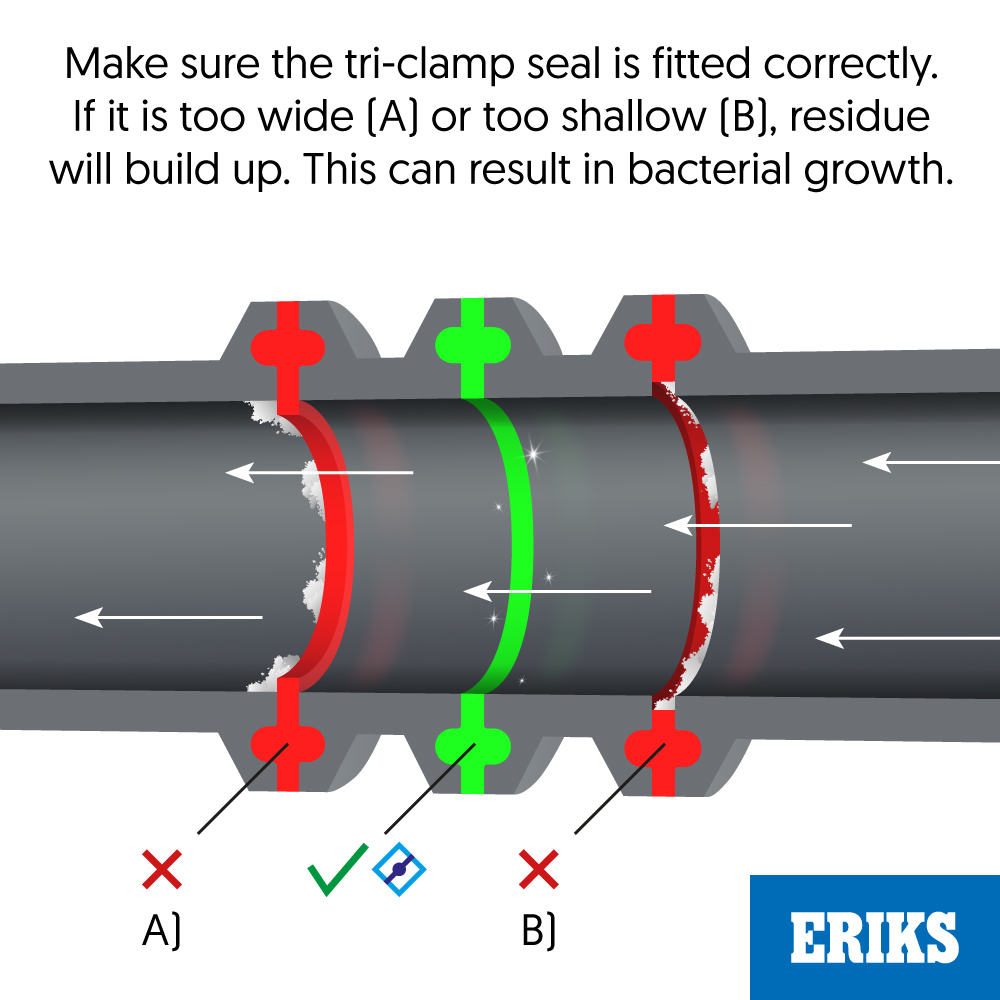

The tri-clamp seal is the most advanced sealing method available. It fits seamlessly into the groove of your seal, minimising bacterial growth.

Have you yet to determine the type of pipe, seal and coupling for your application? The tri-clamp seal is the most food-safe option for the long term.

The tri-clamp seal is a sealing form that minimizes the chance of formation of bacteria. Due to the seamless connection to the groove.

How to choose the correct food-safe seal

When choosing a food-safe o-ring or seal, always consider these factors:

- Type of food substance and temperature

- Cleaning type (SIP or CIP)

- Risk of contamination (e.g. migration or release of rubber particles)

- Groove-connection to prevent bacterial growth

Type of food-substance and temperature

Oils, fats, water, steam, acids: what type of substance does your seal come into contact with? And at what temperatures? NBR or EPDM o-rings are already widely used in the food industry. But there's more. Silicone (VMQ), fluorosilicone (FVMQ) or FKM o-rings (known as Viton) also meet the requirements.

The desired hardness for food-safe o-rings usually ranges between 70-75 (Shore A). Higher hardness values are used with higher media pressure. Lower hardness values are used in combination with limited pressure, or when delicate construction parts (e.g. glass or plastics) are not resistant to higher contact pressures.

Cleaning type: SIP or CIP

An O-ring, or any other seal, must not only be suitable for use with certain substances. It should also match the cleaning method. Choose your seal based on SIP and/or CIP cleaning:

- SIP = Steam In Place. This cleaning method, based on hot water and steam, is frequently used in the production of different types of drinks. Think of fruit juices, where you first produce a load of orange juice, followed by apple juice. Between these batches, you will sanitise the pipes on the basis of SIP.

- CIP = Clean In Place. When feeding different types of food through the same hose, e.g. sauces, oils and fats, the hoses must be cleaned using the CIP method. CIP uses acid and lye to thoroughly clean the hoses.

Note: Check which rules apply for you type of food product and application.

Risk of contamination

Hygiene is especially important for food products. You do not want harmful substances or rubber particles from o-rings to get into your production line. Contamination in the production process has serious consequences. A quick Google search on ‘rubber parts recall’ reveals a large number of cautionary tales.

To minimise risks, you should carefully choose the type of seal that comes into direct contact with food. For example, fragments of metal detectable seals (see our overview of food-safe o-rings below) are easily detected by sensors. This allows you to detect contamination more rapidly and eliminate future risks.

Groove-connection to prevent bacterial growth

A seamless connection prevents dead spaces, eliminating the possibility of product build-up and bacterial growth. That's why a perfect connection between hose, groove and coupling is of vital importance.

Standards: EC1935/2004, FDA and 3A

The most important standards for food-safe materials are defined in the European EC1935/2004 and American FDA standard. O-rings that meet these guidelines have been extensively tested for extraction and migration. The 3A standard has been developed especially for the dairy industry.

All ERIKS food-safe o-rings comply with EC1935/2004 and FDA standards. The tri-clamp seal also complies with EHEDG guidelines, a renowned European knowledge organisation in the field of hygienic design, dedicated to the worldwide standardisation of food safety.

O-rings that meet food safety standards can be recognised.

Food-safe seals – an overview

In these tables you will find the most suitable seals: the material/compound and the corresponding compound number:

O-rings

Compound

Colour

Hardness

(Shore A)

Certificates

CIP & SIP cleaning

Food application

Black

70

EC1935, FDA

CIP, SIP

Acidic, alcoholic, non-fats

Black

70

EC1935, FDA, USP VI

CIP, SIP

Acidic, alcoholic, non-fats

Yellow

70

EC1935, FDA

CIP, SIP

All

Black

70

EC1935, FDA

CIP

All

Red

70

EC1935, FDA, China Food

-

Alcoholic, water-based, dry food

Transparent

70

EC1935, FDA, USP VI

-

Alcoholic, water-based, dry food

Milk gaskets

Compound

Colour

Hardness

(Shore A)

Certificates

CIP & SIP cleaning

Food application

Black

70

EC1935, FDA

CIP, SIP

Acidic, alcoholic, non-fats

Blue

70

EC1935, FDA, China Food

-

Fats

Yellow

70

EC1935, FDA

CIP, SIP

All

Green

75

EC1935, FDA

CIP

All

Red

70

EC1935, FDA, China Food

-

Alcoholic, water-based, dry food

Blue

70

EC1935, FDA

-

Alcoholic, water-based, dry food

Tri-clamp seals

Compound

Colour

Hardness

(Shore A)

Certificates

CIP & SIP cleaning

Food application

EPDM 559273 (without lip, with lip, mini)

Black

70

EC1935, FDA, USP VI

CIP, SIP

Acidic, alcoholic, non-fats

Blue

70

EC1935, FDA, China Food

-

Fats

Yellow

70

EC1935, FDA

CIP, SIP

All

Black

75

EC1935, FDA, USP VI

CIP

All

Silicone 714703 (without lip, with lip, mini)

Transparent

70

EC1935, FDA, USP IV

-

Alcoholic, water-based, dry food

Registering and tracking seals

After installing O-rings or seals in your system, make sure to register the seal-type, material, serial number, location and application. By doing this, food safety is less likely to be compromised due to accidentally replacing an O-ring for a non-food grade version or exceeding the seals intended service life.

Tip: Make food-grade your standard

Want to minimise risk while reducing administrative work at the same time? Then install food-grade seals for each of your machines couplings - even when they do not come in direct contact with food substances. Food-safe and non food-safe o-rings are visually the same. Installing food-grade o-rings throughout your entire system simplifies the audit-process.

Tip: Storage and packaging is crucial

O-rings are no longer considered food-safe when stored outside their original packaging. To prevent o-rings from collecting dust and dirt, keep them in their original packaging at all times. In addition, make sure that o-rings are stored in a dark and dry environment to prevent the rubber from drying out.

For more information on Seals and to get in touch with one of our ERIKS Sealing and Polymer Specialists please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Food #Seals #SealingAndPolymer #FoodSafety #FoodSolutions

Solutions for the food industry

About the food industry

Our blogs on food safety

Consult our Food Experts

Top Tips Whitepaper

ERIKS will handle this - let us know how we can help...