Ageing clarifier drive systems were putting process performance and reliability at serious risk for one northern wastewater company. Each clarifier tank...

Continue reading...KNOW+HOW Hub

Bringing you the latest industry news, views and features, plus technology updates, comments and information.

Search Blogs, Case Studies, Events & News:

Around 4,000,000 passenger journeys are made every day on Transport for London’s (TfL) tube trains. And every day, the traction motors that drive the trains...

Continue reading...When ERIKS was appointed as the first SKF Maintenance Partner in the UK and Ireland, it marked more than just the awarding of a fancy title. It confirmed...

Continue reading...In Energy from Waste (EfW) facilities, few assets are as operationally critical yet often overlooked as the fan systems. Whether supplying combustion air...

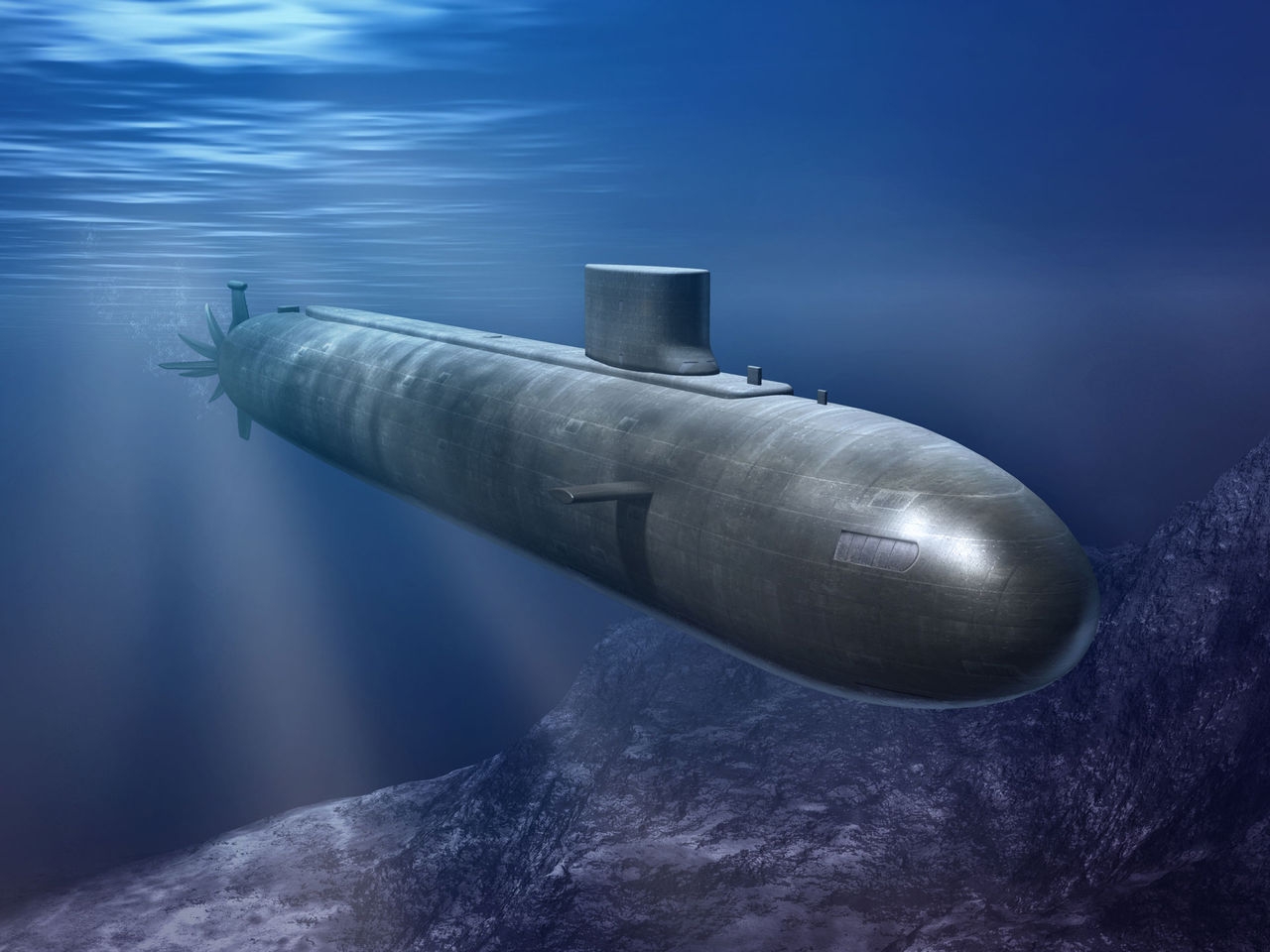

Continue reading...Constructing the Type 31s at Rosyth demands more than advanced shipbuilding expertise. Success also depends on securing a reliable supply of technically...

Continue reading...When maintaining a Royal Navy submarine simulator — a vital training asset valued at over £1 billion — there is no margin for error. Strict security, confined..

Continue reading...Why one customer asked for ERIKS’ help to reduce their supply chain costs, optimise their inventory, reduce the risk of downtime and realise significant savings

Continue reading...Looking for cost savings and efficiency improvements is an important part of operating and maintaining your assets. But have you ever thought that, for the...

Continue reading...To an OEM without the facilities for cost-effective repairs, everything is a replacement. To ERIKS, every job should be assessed on its own terms to reach the..

Continue reading...We all understand the need to reduce CO2 emissions. But while there’s plenty of talk about the challenges for industry, there’s not so much information about...

Continue reading...A conveyor carries a huge load. Not just parts or products, but also the weight of keeping production running and the burden of keeping downtime to a minimum...

Continue reading...Of all the things you might find in a skip, a serviceable gearbox shouldn’t be one of them. But when the original manufacturer assessed a gearbox as failed...

Continue reading...Never miss an update

Trends to digest in KNOW+HOW magazine

Know+How Magazine is the leading magazine for maintenance engineers from ERIKS. Missed an issue?

We explore:

- ERIKS In Action

- In Focus

- Debate

Download your copy today.

Recently read

No blogs have been read by the user

How to Contact ERIKS

Get in Touch

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

How are we doing?

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us or find your local Branch

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000