Grundfos Webinar 2024

Launching ➡️ Tuesday 29th October 2024. Grundfos Webinar focusing on Epumps with guest speakers Konr...

Here are 6x things that you can do now to optimize your Compressed Air System and reduce energy costs!

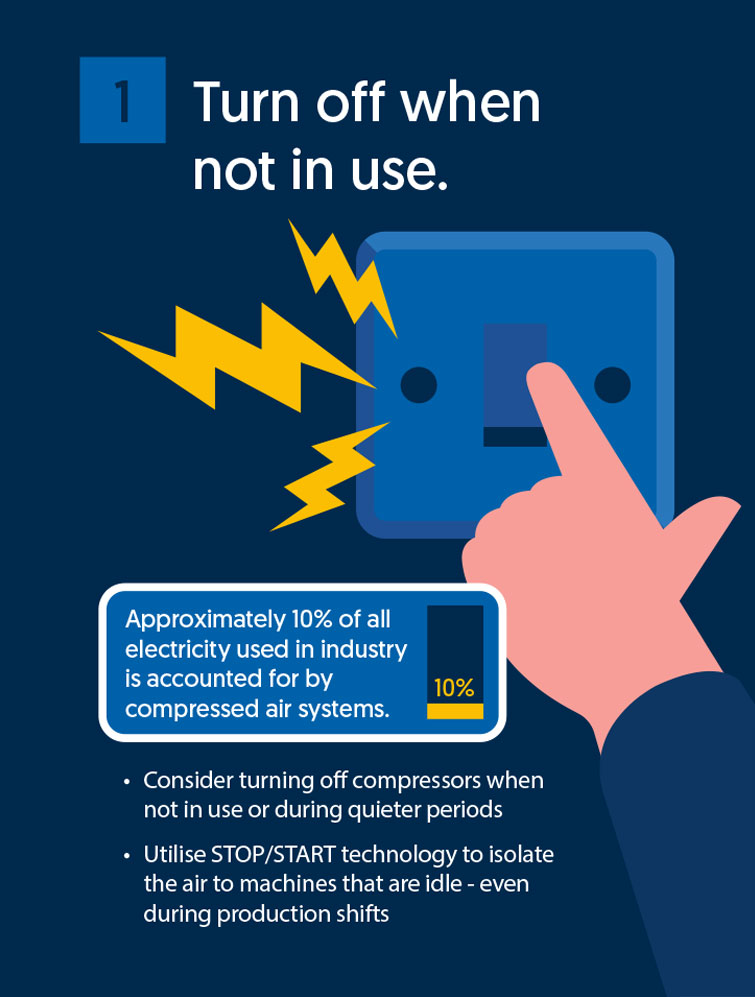

Approximately 10% of all electricity used in industry is accounted for by compressed air systems.

There are 168 hours in a week, but most compressed air systems only run at or near full capacity between 60-100 hours. So depending on a plant’s shift work pattern, you should consider turning off your compressors in the evenings and on weekends.

This could reduce your energy bills up to 20 percent!

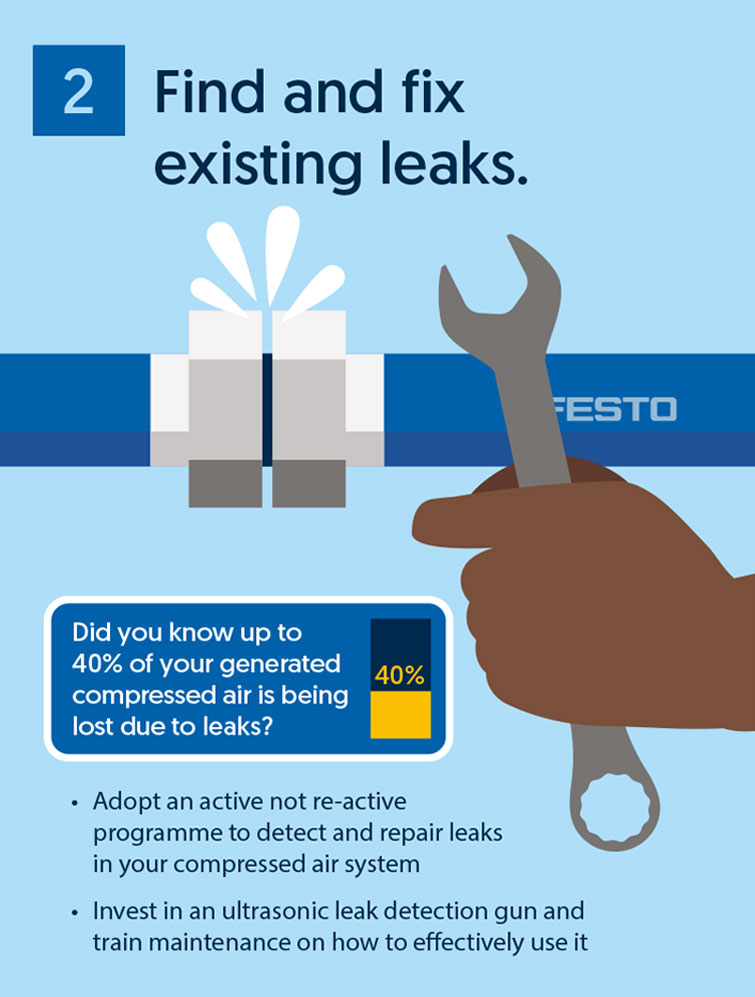

Did you know up to 40% of your generated compressed air is being lost due to leaks? Air leakage is the single largest waste of compressed air. Air leaks tend to be largely ignored because you cannot “see it”. but if you have a liquid leak such as oil or water it is readily visible and often quickly addressed. Yet the cost of a compressed air leak can be much higher.

Approximately 80 percent of air leaks are not audible so one means to detect (and then repair) leaks is to regularly check for leaks using a quality Ultrasonic Leak Detector. Many air leaks are from piping (especially at pipe joints), and from poorly installed or worn out fittings, from valve assemblies and even from stuck auto drains used on filters.

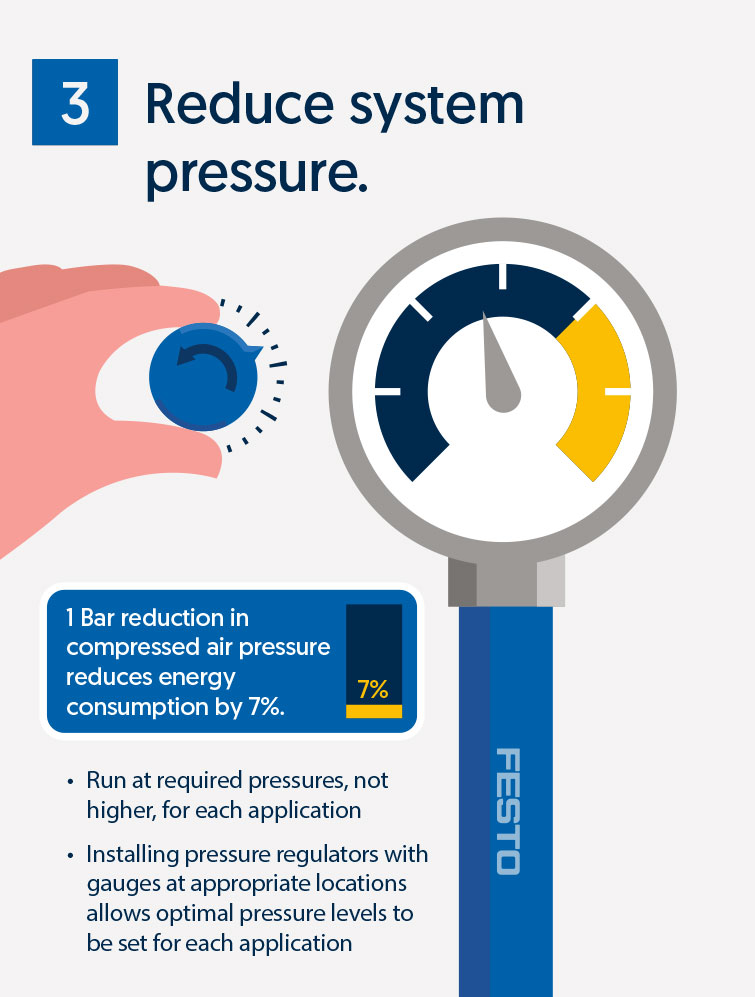

Leaks waste a lot of money. Even fixing a few major leaks helps the bottom line.

Every 1 Bar reduction in compressed air pressure from the air compressor reduces energy consumption by 7%. When a system or machine has issues there is a tendency to increase the supply pressure to compensate this only really feeds the leaks. Pressure regulators with gauges should be installed at appropriate locations so that you can set the optimal pressure level needed for the particular application to ensure minimal compressed air use. If a machine has a single operation that requires a higher pressure to perform then you should look at solutions that can overcome this situation such as a localised pressure booster while maintaining the general machine at a lower overall pressure.

About 70% of compressed air products (after leaks) is used for blowing off, cooling or the production of vacuum. Inappropriate applications include any application that can be done more effectively or more efficiently by other means than using compressed air such as the use of Air Blowers and Vacuum Pumps whose actual running costs can be significantly lower than the cost required to generate the compressed air used. That being said, however, compressed air is often used where for any number of reasons these other options cannot be used such as available of space, location or lack of local support for another technology.

So rather than demonising the use of compressed air, we should look at equipment to maximise its efficiency for example it can be applied very efficiently for blow off, drying and cleaning by using energy efficient items like air nozzles, and other air “amplifiers” both annular type and linear or “air knife” versions that converts energy normally lost as pressure drop and noise into high velocity and high volume flow. This type of technology can reduce compressed air costs at point of use anywhere from 10% to 90% while maintaining production rate output and quality.

You can’t put in place cost saving initiatives until you know what’s happening in your system. Investing in equipment to measure pressure, volume flow and leaks has the following cost-savings benefits.

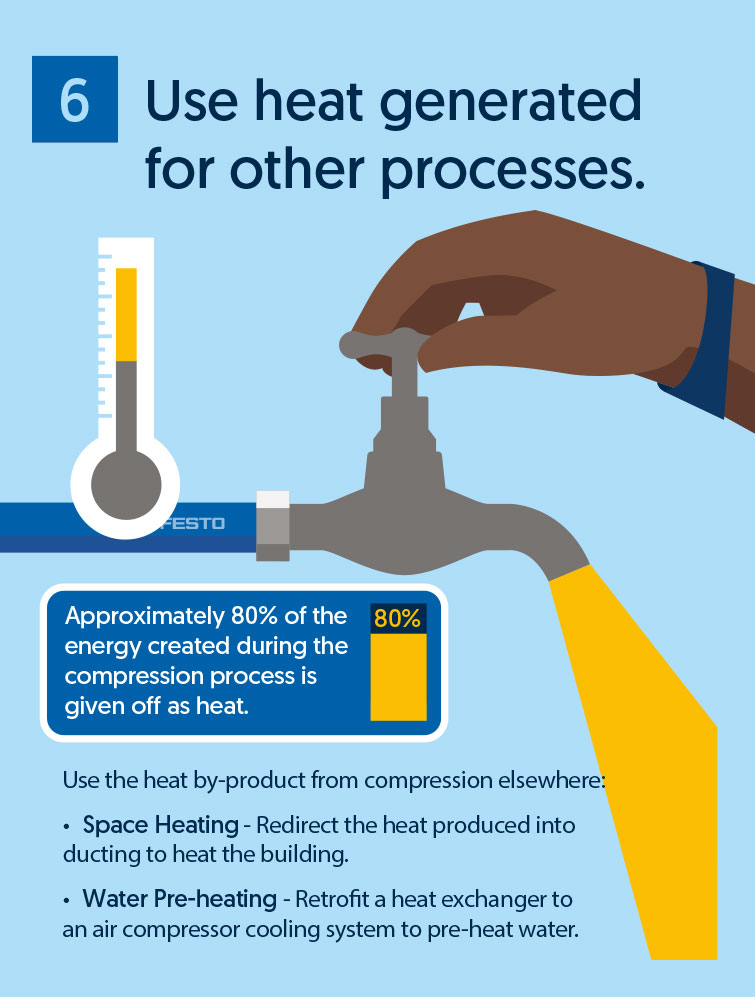

Approximately 80% of the energy created during the compression process is given off as heat. This heat is usually given off into the atmosphere and wasted. For example, an 11Kw compressor has the potential to lose up to 9Kw in heat energy!

Use the heat by-product from compression to save costs elsewhere. Redirect this energy, for example into ducting to heat the building. Or you can retrofit a heat exchanger to an air compressor cooling system to pre-heat water.

The new home for ERIKS News, Blogs and Case Studies - keep up to date with all the latest news and updates in one place

The latest:

For all general enquiries use the Enquire Online form - we'll connect you with the best member of our team for your query. Alternatively, look up your local service centre...

We are proud to boast a strong team of technical specialists in each of our product and service areas. If you have a technical question a member of our team would be happy to help.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.