In this article

Food hoses: examples, standards, tips

Reputation damage or lawsuits. It can happen when you do not have your food safety in order. Food safety is all about regulations, product traceability and the use of food-safe products and components. Are you sure you are using the right type of hose? We are happy to advise you on how to choose the most suitable hose for your application.

EC1935/2004 explained

Hoses must comply with European legislation EC1935/2004. This contains requirements for materials (plastics, rubbers, metals and silicones) that come into contact with food. Migration tests (described in legislation EU10/2011) are used by the manufacturer to prove that a hose meets all requirements. Request the results of the migration test directly from the manufacturer.

Failure to use food-safe hoses significantly increases the risk of contaminating food items.

This may lead to:

- Health risks

- Changes in food composition

- Impaired smell, taste and colour

Want to know more about EC1935/2004 and EU10/2011? Read our article about food safety laws and regulations.

Food-safe hoses for your demands

Not every material is suitable for all food substances. Some hoses are resistant to oils and fats, while others are better suited to powders. We have listed some common foods products, including our hose recommendations.

Note: This is a guideline. Always consider other variables in your application, such as temperature, pressure, length of exposure and cleaning process. Don't know which hose will meet your requirements? Get in touch with our specialists.

Dairy and oils

Do you work with milk, cream, vegetable oils or mayonnaise? Then NBR hoses are very suitable. They are also very compatible for soft drink applications.

Beverages

We recommend different types of hoses for all types of drinks (alcoholic/non-alcoholic): EPDM, PTFE, PVC and NBR. Apart from choosing the correct hose-material, it is important to consider the compatibility with your application in general, including the cleaning process.

Powders

Do you work with dry ingredients, such as milk powders or spices? We recommend polyurethane or NBR hoses. Powders are an abrasive substance. That’s why hoses need a wear-resistant inner wall. Polyurethane is well known for this feature; not many people know that NBR possesses this quality too.

Static electricity arises during the transportation of powders. That’s why we also supply hoses in antistatic versions. Please note: NBR food hoses with white inner walls are not antistatic by default. The ERIKS Power Food Spiral is - full information here.

Water

Any type of hose is suited for water. You can use PVC, NBR, EPDM or stainless steel.

Material characteristics of food-safe hoses

Food-safe hoses are often made of PVC, PTFE, polyurethane, NBR or EPDM. Check the characteristics of the EC1935/2004 certified materials:

PVC hoses

- Temperature range from 20°C to +60°C.

- Transparent, light and (usually) very flexible.

- Not suited for oily substances.

- Withstand limited pressure and temperature.

Top pick: choose Premium Multibar or Polymetra Clear. These are the most basic EC1935/2004 compliant PVC hoses available.

PTFE hoses

- Temperature range of -70°C to +260°C.

- Suitable for use in applications involving extreme temperatures, pressure or movement.

- Highly suitable as supply hoses for filters and centrifuges, drying towers and for use in adding aromatic substances or flavourings.

- Highly resistant to chemicals and easy to clean.

Top picks: choose smooth, corrugated or externally corrugated hoses.

NBR hoses

- Temperature range from -30 C to +100°C.

- Oil and fat resistant. Well suited for milk, cream, vegetable oils and mayonnaise.

- Highly suited for soft drinks.

- Spiral or spiral-free versions available.

- Can also be used as transporter hose.

- Please note: too much detergent in combination with high temperatures will corrode the rubber.

Top picks: choose Nutralon, Nutralon SD Lite or Nutralon SD. These are quality hoses with great specs.

Polyurethane hoses

- Temperature range from -40°C to +90°C.

- Suited for powders and other dry, abrasive substances.

- Highly resistant to grease.

- Antistatic versions available.

- Not suited for high-temperature applications

Top picks: Choose Abraflex MD Food or Abraflex MD Food AS-INOX. These are, in our opinion, the best hoses for the food industry, especially for powders.

EPDM hoses

- Temperature range from -30°C to +90°C.

- Well suited for beer, soft drinks and wine.

- Electrically conductive version available for drinks with a high alcohol content.

- Can also be used as cleaning hose like Premium Cleanfixx FDA (with a temperature range of +164°C).

- Not suited for use in combination with fats and oils.

Top picks: opt for Premium Delifixx, the Purpur slang, Premium Cleanfixx FDA or the Blue Guardian. These are high-quality hoses with great specifications.

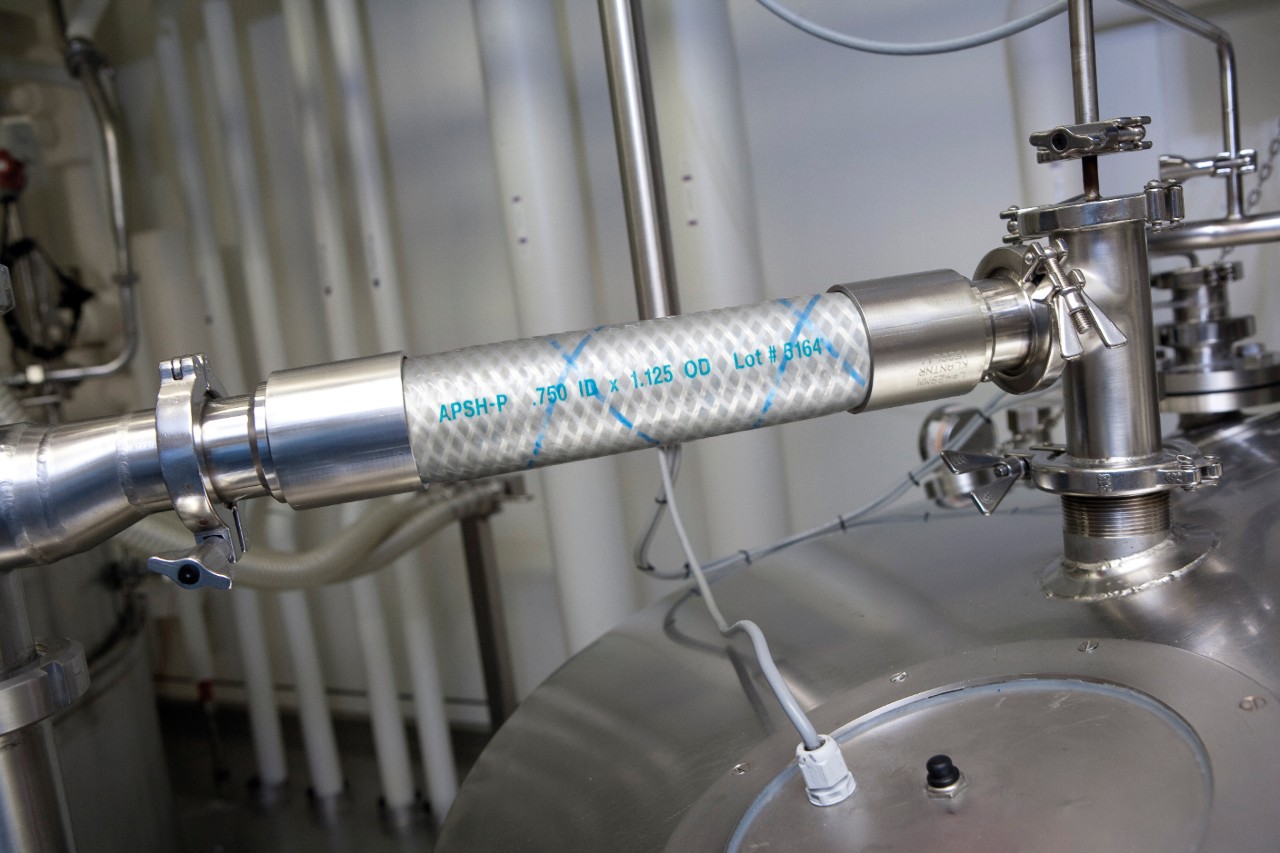

Stainless steel hoses

- Temperature range of -196 °C to + 550 °C.

- High temperature resistant.

- High pressure resistant.

- Note: standard stainless steel hoses are difficult to clean due to their corrugated inner wall.

- Not suited for vibration absorption.

Stainless steel hoses are rarely used in the food industry due to their corrugated inner wall which is hard to clean. An exception is for use in high-temperature applications (up to + 600°C), sometimes only a stainless steel hose will suffice. For these applications we recommend the 161 food hose. This hose has a flat corrugation, making it easier to clean.

Couplings for food-safe hoses

You can connect any type of food hose with couplings like: DIN11851, DIN11864, Tri-clamp, flange, and many more. For example, take a look at the GOODALL coupling. Coupling assembly differs per hose.

Cleaning food-safe hoses

There are different cleaning procedures in the food processing industry. For wet floor cleaning (hot/cold), use a rubber hose on a reel. This is easy and light to use. In other places where for example fixed CIP hoses are installed, we advise a PTFE or stainless steel hose. Possibly with a rubber/silicone sleeve. For cleaning the application with steam or hot water, we advise EPDM.

For more information on Hose solutions and to get in touch with one of our ERIKS Fluid Power, Transfer and Control Specialists please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Food #Hoses #Goodall #FoodSafety #FoodSolutions

Solutions for the food industry

About the food industry

Our blogs on food safety

Consult our Food Experts

Top Tips Whitepaper

ERIKS will handle this - let us know how we can help...