In this article

Creating a 21st Century Fulfilment Centre of Expertise

In the last twelve months, we’ve seen an unprecedented series of shocks to international supply chains. A crisis that began with worldwide Covid pandemic lockdowns has been exacerbated by a growing sequence of challenges, ranging from the chaos caused by the grounding of the Ever Given container ship that blocked the Suez Canal for 6 days, to a worldwide shortage of semiconductors.

In the UK, the situation has been further aggravated by issues caused by Brexit and the track and trace pingdemic, with shortages of HGV drivers and key workers in warehousing, logistics and retail disrupting the supply of industrial and consumer goods. Most forecasters expect the situation to deteriorate further in the coming year.

The speed and extent of supply chain disruption may be unprecedented, but the fundamental requirements of customers remain unchanged: the ability to source products from trusted suppliers and to be able to access those products where and when they need them. Predictability, consistency and reliability of supply are vital.

Building for the future

We couldn’t have predicted these short-term supply-side shocks. But our position at the heart of the industrial supply chain allows us to understand the underlying factors that are driving longer-term change, and to develop solutions that are resilient, agile and future- proof – solutions that help our customers cope with whatever challenges come their way, no matter how tough.

We’re therefore developing a dynamic industrial distribution model. At its core is a multi-million pound investment in a new Fulfilment Centre of Expertise and UK Headquarters. This has recently been opened in Oldbury, in the West Midlands.

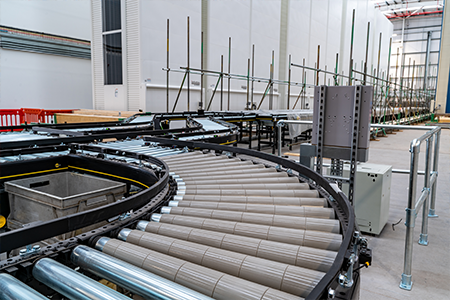

The FCE and what it means for you The Oldbury Fulfilment Centre of Excellence (FCE) sits at the heart of our nationwide network of local distribution and specialised engineering service centres. It replaces two existing distribution hubs, bringing a 53% increase in capacity, with considerable potential to meet future demand. Look inside and you’ll see a unique combination of 21 high speed lifts, integrated with over 400m of rapid transit conveyors and vertical racking with capacity for 11,200 Euro pallets.

This automated, high-speed operation is controlled by the latest Industry 4.0 warehouse management technology, interconnected with sophisticated pick-to- light, scanning, vision and weighing systems, and with our company-wide ERP systems; in time, we’ll extend this connectivity to give customers real-time access to their orders.

Our goals are simple, to:

- Stock the exact products you need

- Deliver the right products every time

- Supply products to you faster

- Give you end-to-end visibility

- Support your future growth

Fulfliment Centre of Expertise image gallery

FCE Office Space

FCE Personal Storage Area

FCE Canteen Facilities

FCE Meeting Room

FCE Breakaway Area

High Speed Conveyor System

Vertical Lean Lifts

Warehouse Vertical Storage

Data, accuracy and speed of response

Our investment in the latest warehouse technology is a crucial component in our drive to deliver exactly the right products to each customer, on time, every time. We are, for example, already able to achieve a 30% increase in picking-speeds and are striving for consistent, 100% pick-accuracy.

Key to this is our ability to capture and analyse vast amounts of live data and then to adapt our processes dynamically. Our new systems provide advanced capabilities such as real-time stock level monitoring, customer- demand profiling and automatic reordering.

At a shop-floor level, our integrated systems allow us to track, trace and pick efficiently, while optimising the location of fast-moving products to increase pick-speeds. Similarly, to enhance efficiency and accuracy still further, all goods-in consignments are fully inspected and quality checked on arrival. They are then checked again when they are picked and receive a final scan and check-weigh before despatch.

This end-to-end tracking process ensures precise stock control and 100% stock availability.

Industrial strength CX

We already work closely with many of our customers and have developed a range of fulfilment, engineering and technical and commercial support services to help customers derive significant value from our relationship. The new FCE will allow us to strengthen this offering, while building the foundations that will help us offer a customer experience that we believe will set new standards for our sector.

At a practical level, the adoption of automated warehouse and intelligent stock management technologies enable us to work faster and more efficiently than ever before.

They also release key members of our team across the UK and Ireland to focus on the vital areas of customer communication and collaboration, offering the technical and commercial knowledge, experience and insight that help customers improve their productivity, performance and profitability.

Our new Oldbury FCE is a cornerstone in a strategic long-term investment programme that will create the industrial supply chain and engineering service matrix of the future. It’s a future that is smart, interconnected and agile; a future where we’re able to provide every customer with the supply chain security, flexibility and confidence to meet fresh challenges in an ever-changing world.

- Over 11,000 square metres of warehouse space

- 15 vertical lifts

- More than 400m of high- speed conveyors

- One of the most advanced warehouse management systems anywhere in the UK

- Sophisticated scanning and weighing systems for every order

- Robust I4.0 configured IT infrastructure with real-time monitoring

The Oldbury Fulfilment Centre of Expertise is much more than just our latest and most advanced fulfilment hub. It is also our new UK headquarters, with over 11,000 m2 of light, open and energy-efficient workspaces, designed using the latest architectural and behavioural insights.

Our goal is to create an environment where our specialist teams can develop novel ideas and innovative solutions that strengthen our support for customers, while bringing a fresh approach that resolves complex supply chain and manufacturing challenges.

Our new Oldbury Centre represents a significant investment for ERIKS. It makes a strong statement of intent about the importance and value that we place on all our customers, employees and stakeholders, and provides the critical foundations that will support future success and prosperity.

For more information on any of our solutions and to get in touch with your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Engineering #CX #IntegratedSystems #SupplyChain