In this article

What's the Point of Pump Efficiency?

Every pump has a Best Efficiency Point (BEP). And finding it will not only mean the pump will use the least energy for the highest performance. But also by operating your pump at or near its Best Efficiency Point, it will also mean increased reliability, so it pumps better, for longer.

Operating far off its BEP was one of the problems with the pumps examined by ERIKS at a waste water pumping station, which had suffered a number of premature and catastrophic pump failures.

The site was spending £180,000 per annum on pump repairs, and there were also a significant number of emergency call-outs, which were only adding to the high operating cost of the pumping station. They requested a Root Cause Analysis, to try to identify and resolve the issues.

Damage Report

A first inspection for physical damage revealed a failure mode which was consistent with:

- Drive end bearing failure

- Mechanical seal failure

- Recirculation erosion

- Cavitation on the impellers.

However, to carry out a full Root Cause Analysis, ERIKS’ engineers had to undertake a complete pump system audit, to understand how the performance of the pumps at the site interacted with the hydraulic system curve.

The audit included data logging of power, head, flow and system pressure, over an extended period, followed by detailed expert analysis of the results.

Revealing Results

The results of the investigation proved very revealing.

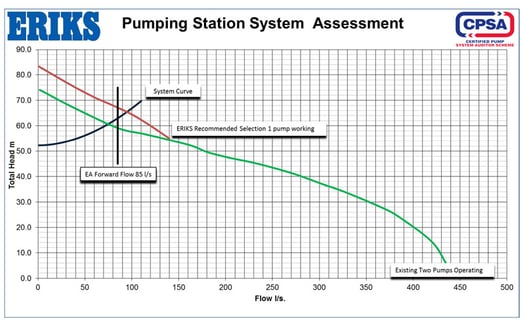

Firstly, they showed that even with two pumps operating in parallel – the current practice at the site – they were not meeting the statutory flow, which meant a heightened risk of waterways pollution.

Secondly, the pumps’ intersection with the system curve was far off the BEP. This meant that mechanical stress was greatly increased, and the pumped media was highly likely to be recirculated. Operating pumps in these conditions can also lead to an increased tendency for clogging-up, which then creates excessive vibration, which in turn increases wear and tear on the equipment.

Improved Pump Performance

With the audit and analysis complete, ERIKS’ engineers were able to plot a hydraulic system curve which showed which new pumps would not only meet statutory flow requirements, but would also do so whilst operating always at maximum efficiency.

In fact, the pump selection proposed by ERIKS:

- Reduced the number of operating pumps required from two to one

- Increased the flow rate from 75 litres per second to 90.5

- Reduced power absorbed from 90kW to 82.9kW.

The time to pump 100m3 was also reduced – from 1.33 hours to 1.11 hours – and the total power usage to pump that 100m3 was cut from 120kW to just 91.6kW.

Under ERIKS’ proposal, this performance would also be achieved whilst operating the single pump within its optimum deign envelope. This would obviously reduce the energy absorbed, but would also have the effect of increasing the reliability and longevity of the pump.

Identifying, assessing and improving the performance of pump systems is something which ERIKS engineers do almost every day.

For more information on Flow Control solutions and to get in touch with one of our ERIKS Pumps Specialists or Valve/Flow Control Engineers, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #PumpEfficiency #Efficiency #Flow #Solutions #Pumps #EngineeredPumps #PumpManufacturing

(Blog post updated: 13-12-2021)