In this article

When the going gets tough

Bearings keep machines and equipment moving. But what happens when everything else is doing its best to stop them? In mining, quarrying, steelmaking and construction, it can seem as if invasive contaminants, excessive heat and heavy loads are all out to get your bearings and compromise their service life. Luckily NSK is on your side.

In any industry, downtime is the enemy. And in heavy industries operating in aggressive environments, the enemy has plenty of weapons.

In mines and quarries, debris and contamination can easily penetrate poorly specified bearings. And in steel foundries, metal particles or debris can contaminate lubricant and create dents in the rolling surfaces of bearings – leading eventually to cracking and surface flaking.

So, to have any chance of winning the battle, avoiding unwanted maintenance and repair costs, and preserving bottom-line profitability, bearing selection is critical.

Self-preservation

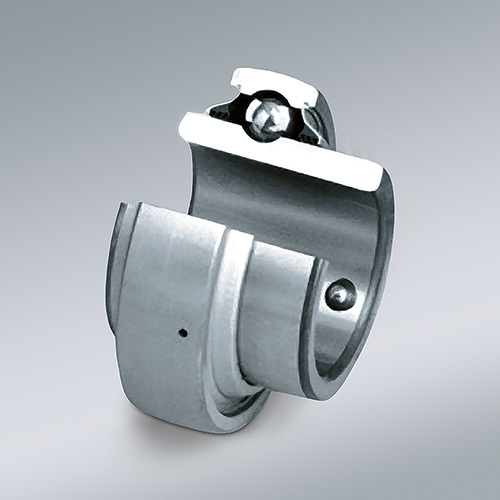

On the battlefield that’s an aggressive operating environment, NSK Self-Lube® bearings stand out for their survival skills. It’s not only their state-of-the-art design, but also their construction material, lubricant and seals.

And by selecting NSK Self-Lube® bearings with triple lip seal and shaft end protectors, downtime and repair costs can be reduced even further.

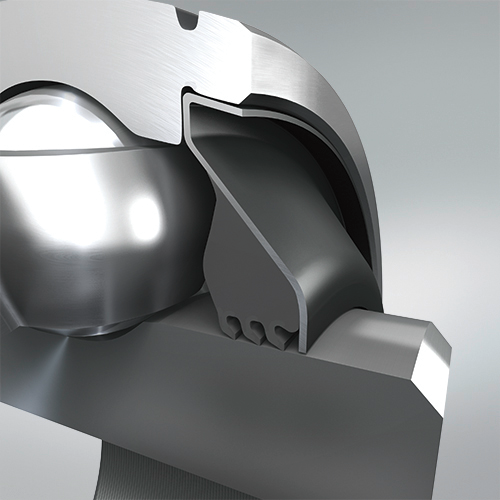

The NSK triple-lip seal is a one-piece moulded nitrile seal with three lips, bonded to a protective outer steel pressing secured in the outer ring. Self-Lube® bearing inserts also have a locating groove to allow the easy fitting of an optional end cap, to protect the bearing from external contamination.

Steel yourself

There’s no room for weakness in the steel industry. But NSK’s long-life Super-TF spherical roller bearings are more than up to the challenge.

Their specially-developed Super-TF bearing steel has the proven ability to reduce surface-originated flaking from contaminated lubricant. So the bearings increase service life and uptime significantly, even in very high load applications.

in 2017, independent testing certified that Super-TF bearing steel can improve the basic dynamic load rating in roller bearings by 23%. That equates to an effective doubling of fatigue life in comparison with standard steel bearings.

Drums beaten

NSK bearings have successfully solved problems and saved money for many customers in the mining and quarrying sector.

One operator was experiencing frequent reliability problems with the bearing units assembled in a vibrating drum. These bearings suffer exposure to sand that often completely covers the units. Following a comprehensive failed bearing analysis, NSK proposed Self-Lube® bearing units with triple lip seals – which increased the operating life by a factor of 10 against the previous solution.

Another company supplying ready-mixed concrete and other construction materials invited NSK to perform an similar review of failed lower bearings on its augur screw pump. This pump transfers an abrasive mixture of ash, sand, glass, fibres and metal grit into containers.

NSK’s engineers discovered the contact seal that runs against the inner ring of the bearing had worn away, allowing contamination into the bearing. Further problems included heavy cage corrosion and absence of lubrication. The ingress of fine dust and particulates had most likely soaked up any grease and created a grinding paste, which then eroded the rubber seal.

NSK recommended Self-Lube® bearing units, with the inclusion of a small disc plate and additional seal. This minor redesign not only helped to stop most of the contamination but – as it features a path for debris to escape – also significantly reduced pressure on the bearing seal.

Put through the mill

NSK roller bearings have proved equally effective in the steel industry.

One steel manufacturer was experiencing cold rolling mill bearing failures every 3-4 months. Analysis of the failed bearings and grease samples by NSK’s engineers revealed that the rolling mill’s highly contaminated operating conditions were the cause of the bearing failures, costly unplanned shutdowns and reduced production.

NSK’s experts recommended Super-TF spherical roller bearings to combat debris in the lubricant. After a four-month trial, the steel plant returned the bearings to NSK’s laboratory for inspection, where X-ray fatigue analysis revealed a residual life of 29-50 months. This led to annual savings – from less frequent bearing purchase, reduced downtime and lower maintenance requirements – totalling €16,300.

Life is definitely hard for bearings in many operating environments. But when the going gets tough, tough NSK bearings get going.

For more information on Bearing Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#NSK #ERIKS #LetsMakeIndustryWorkBetter #Bearings #SelfLubrication #Mining #Quarrying