ERIKS and SAI Automotive Fradley OnSite

Lee Matthews’ relationship with ERIKS goes back a long time to 2002 when the site he was working at was moved into the current site Lee took ERIKS with him...

Use ERIKS supply chain and inventory knowhow to release time and capital caught up in your indirect or maintenance, repair and operations OnSite supply chain.

Are these issues familiar?

Maximising the performance of your engineering stores is not your businesses’ focus. Achieving or maintaining world-class manufacturing performance is your focus; this is where ERIKS’ OnSite integrated supply chain business and yours intersect.

ERIKS’ OnSite integrated supply chain offer is simple. Our specialist team takes responsibility for integrated supply, vendor-managed inventory (VMI), MRO procurement, inventory control, and full engineering stores management - all while being based on your site.

We eliminate supply chain inefficiencies while giving you greater control, visibility, and cost savings. By outsourcing to ERIKS, businesses can access real-time data insights, better pricing, and improved stores performance, all while reducing administrative burdens.

At ERIKS, we recognise that in today’s complex industrial landscape, efficient MRO management is not just about convenience—it's a strategic advantage.

Discover key insights in our "5 Ways to Enhance Your Maintenance, Repair, and Operations (MRO) Supply Chain" guide and learn how industry leaders optimise efficiency, minimise downtime, and drive cost savings.

Switching from in-house MRO stores management to outsourcing can seem daunting. However, at ERIKS, we've designed a process that makes it simple, risk-free, and highly efficient.

ERIKS has developed a high-level industry guide designed to help manufacturing sites optimise MRO operations, reduce downtime, and improve cost efficiency.

Discover how outsourcing MRO stores management can streamline operations, enhance reliability, and drive sustainable growth.

The results are in!

We have now completed the 3rd Maintenance, repair and operations supply chain survey and the results are in.

Unlock new Insights from ERIKS & the IET using this research to identify problem areas to transform your MRO supply chain with the actionable insights provided in our report. Download your copy today and join the ranks of industry leaders dedicated to excellence and innovation.

Get your copy of the report today.

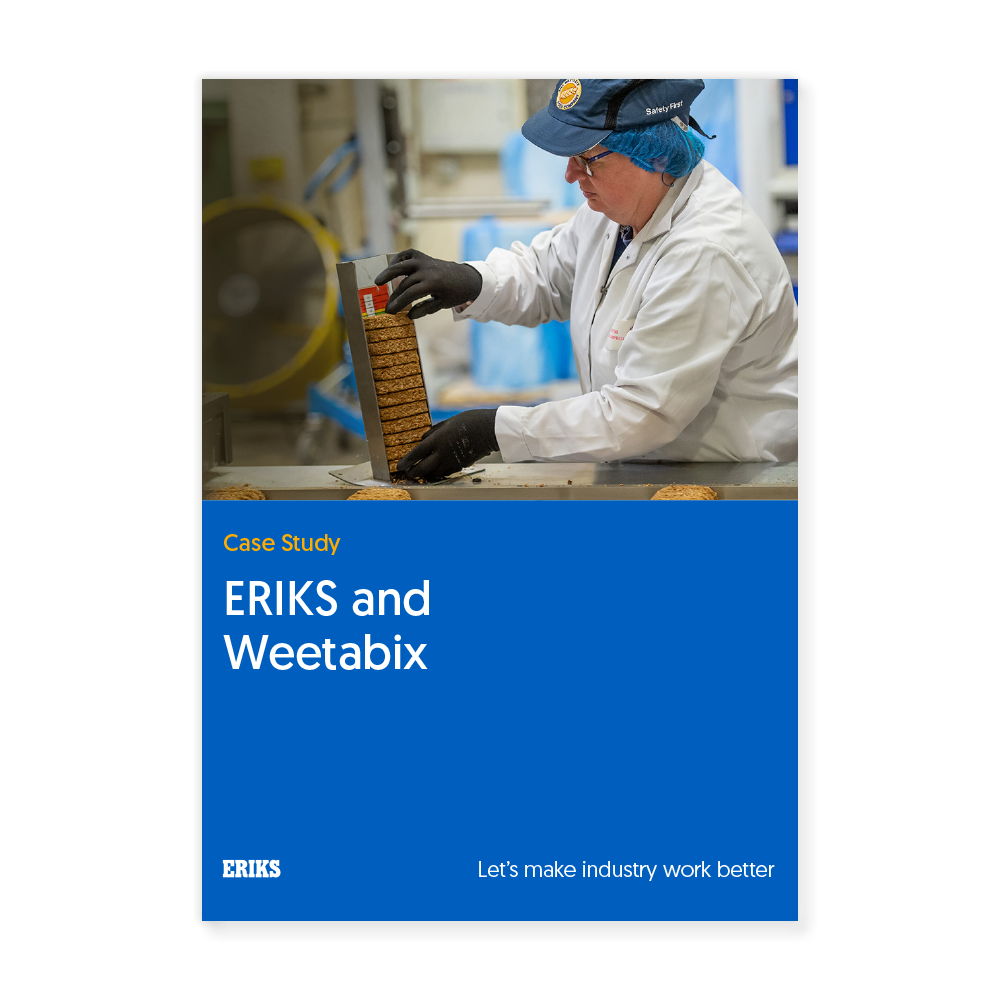

ERIKS and Weetabix go back a long time with ERIKS' team first coming onsite to run the engineering stores more than 20 years ago.

Weetabix is an iconic brand and the sheer volume of product that it makes at its Burton Latimer and Corby sites is dizzying. The Weetabix brand has 12 lines, and on average each produces 72 dozen biscuits per minute. That’s 864 biscuits per minute per line or 622, 080 biscuits per hour or 14,929,920 each day!

Lee Matthews’ relationship with ERIKS goes back a long time to 2002 when the site he was working at was moved into the current site Lee took ERIKS with him...

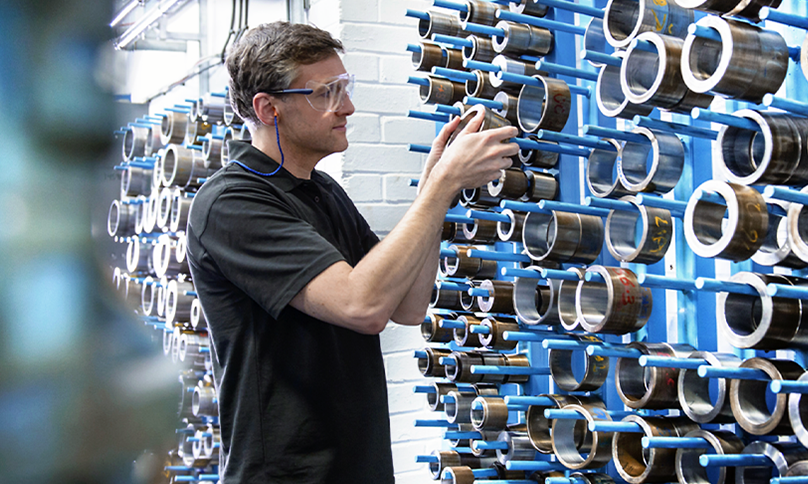

Throughout this extensive history Steel & Alloy has undergone three or four significant evolutions in their service contract renewals with ERIKS...

Expertise in procurement, inventory and product to release time and capital caught up in maintenance, repair and operations supply chain.

Save time sourcing and procuring products with our powerful eCommerce tools.

Helping your engineering stores to run efficiently saving time & money, incuding vending solutions.

A secure online ERIKS store to manage your account, track your enquires and orders as well as request quotes and technical support.

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000