In this article

Decision making based on numbers

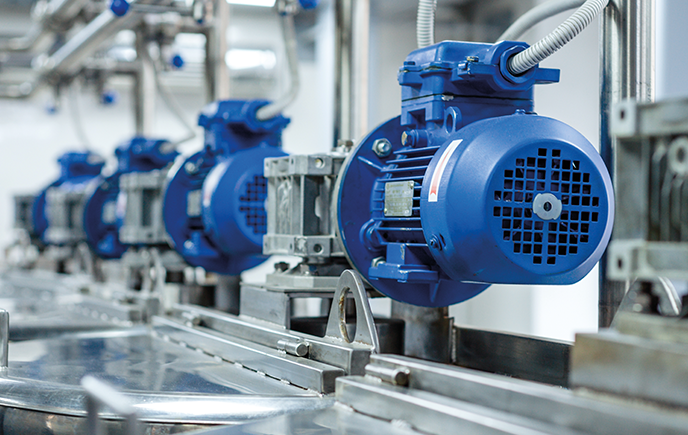

One of your critical electric motors has failed. Production’s ground to a halt. The pressure is on you to get operations back up-and-running as quickly and cost-effectively as possible. A quick price comparison of various new motors, a quote for a repair, and the numbers seem to make it clear which is the cheapest way to go. But is it the right way in the long-run?

The problem with basing your decision on the numbers on the price tag is that they don’t tell the whole story – because the most scary part has been left out. The purchase price is a mere 1% of the Total Cost of Ownership (TCO) of any electric motor. Maintenance adds another 2%. But the remaining, frightening, 97% of the TCO is entirely down to the cost of electric energy.

So you’re making a purchasing decision based on just 1% of the relevant information. In other words: you’re buying an iceberg.

But a new online tool from ERIKS means the number’s up for short-term thinking and inefficient electric motor purchases.

Efficient – by law

Clued-up purchasers like you are not the only ones looking at the operating costs, energy consumption and carbon emissions of electric motors. Governments are well aware that these motors in industrial applications represent 65% of all energy consumption. And where energy goes in, CO2 emissions tend to come out.

In one year alone electric motors in the EU have consumed 1,425TWh of electricity, which corresponds to 560 tonnes of CO2 emissions.

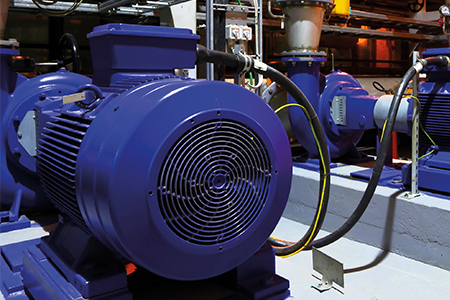

The new ERIKS Total Cost of Ownership Calculator is the answer.

It not only gives you the right numbers. It also lets you see how they all add up, to help you make the correct motor choice for the long-term.

Tailored TCO calculations

Every electric motor application is different. So there’s no real benefit from a one-size-fits-all calculation of the cost of ownership. That’s why the ERIKS online TCO Calculator bases its results on a whole range of factors unique to your specific application.

The TCO Calculator allows you to input your unique figures for:

- running hours

- energy costs and

- repair cost

This means the answer the TCO Calculator gives you will be 100% relevant to your specific application.

When a motor has a design life of 15-20 years, incorporating these detailed figures into your purchasing considerations has a major influence on the TCO, and highlights even further the significant difference between what the motor will cost you to buy and how much it will really cost you to own.

ERIKS’ repair/replace neutrality also means the calculator provides costs for basic repair (if possible). These take into account the fact that a non-standard motor may be quicker to repair than replace, but at the same time allow for the likely lower energy-efficiency of a repaired motor – compared with a new one of the same or higher efficiency rating.

Calculate, choose, click – and buy

Although the ERIKS TCO Calculator has been operational for a while, the latest update offers even greater functionality.

It’s now hosted in the ERIKS Webshop, so you can make your decision and then make your purchase with just a few clicks. One click will reveal the full specification of the suggested replacement motor, and you can then click to buy. Alternatively, you’re only a click away from arranging a repair, if that’s your preferred option.

So now, making a well-informed, cost-effective decision about your next electric motor is quicker and easier than it’s ever been.

Try out the TCO Calculator for yourself today or for more information you can contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #TotalCostofOwnership #TCO #Savings