In this article

A new valve turns on the savings tap

ERIKS engineers have their eye on the ball

Industry Sector:

Construction

Application:

Gypsum mill tank

Actual Saving:

£20,000

Payback period:

Immediate

Product/Service:

- Valves

Customer Benefits:

- Cost reduction

- Improved reliability

- Minimised downtime

- Enhanced supply chain

- Optimised maintenance efficiency

Sometimes, before anyone notices, recurrent downtime, frequent maintenance and repeated parts replacement become established practice. They are factored into running costs and recognised as ‘the way we do things’. Then something unavoidably changes – and doing nothing is no longer an option. But contacting ERIKS is.

Steadily increasing repair costs, and their sudden leap during the Covid pandemic, convinced a major manufacturer of gypsum products that it was time to address the recurring issues with the ceramic seated ball valves feeding into their mill tanks.

Challenge

The OEM ceramic seated ball valves fitted to two mill tanks were frequently jamming, leading to repeated emergency shutdowns and significant financial losses.

Unpredictable failures were occurring as frequently as every 4-12 weeks, and engineer callouts were sometimes taking place in the early hours of the morning. In addition, as the valves failed, the ball and seats were being damaged, leading to reduced operational efficiency.

Maintenance was complex due to the brittle nature of the ceramic valve seats, which would often break during replacement. Lead times for new valves were 16 weeks, so once the failed valve had been replaced with the spare from stock, the old valve would be overhauled and retained for the next emergency swap-out. However the customer was still exposed to the risk of excessive downtime if on-site stocks ran down.

By the time the customer contacted ERIKS, the cost of replacement parts for a single valve had risen to £7,500.

Solution

An ERIKS Application Engineer visited the customer’s site to gather detailed information on the valve’s specific performance issues. This was followed by a joint visit with an engineer from KDV Flow Limited – an ERIKS preferred partner. On this second visit, as well as collecting more data, the OEM ceramic seated valve, actuator and associated accessories were closely inspected and assessed.

The findings led to a recommendation to replace the ceramic seated valve with a new, customised, diaphragm-style model, more suited to the operating conditions of the specific application. The new design is better able to cope with the fine powder and abrasive materials present in the mill tanks, which were causing the problems with the ball valve.

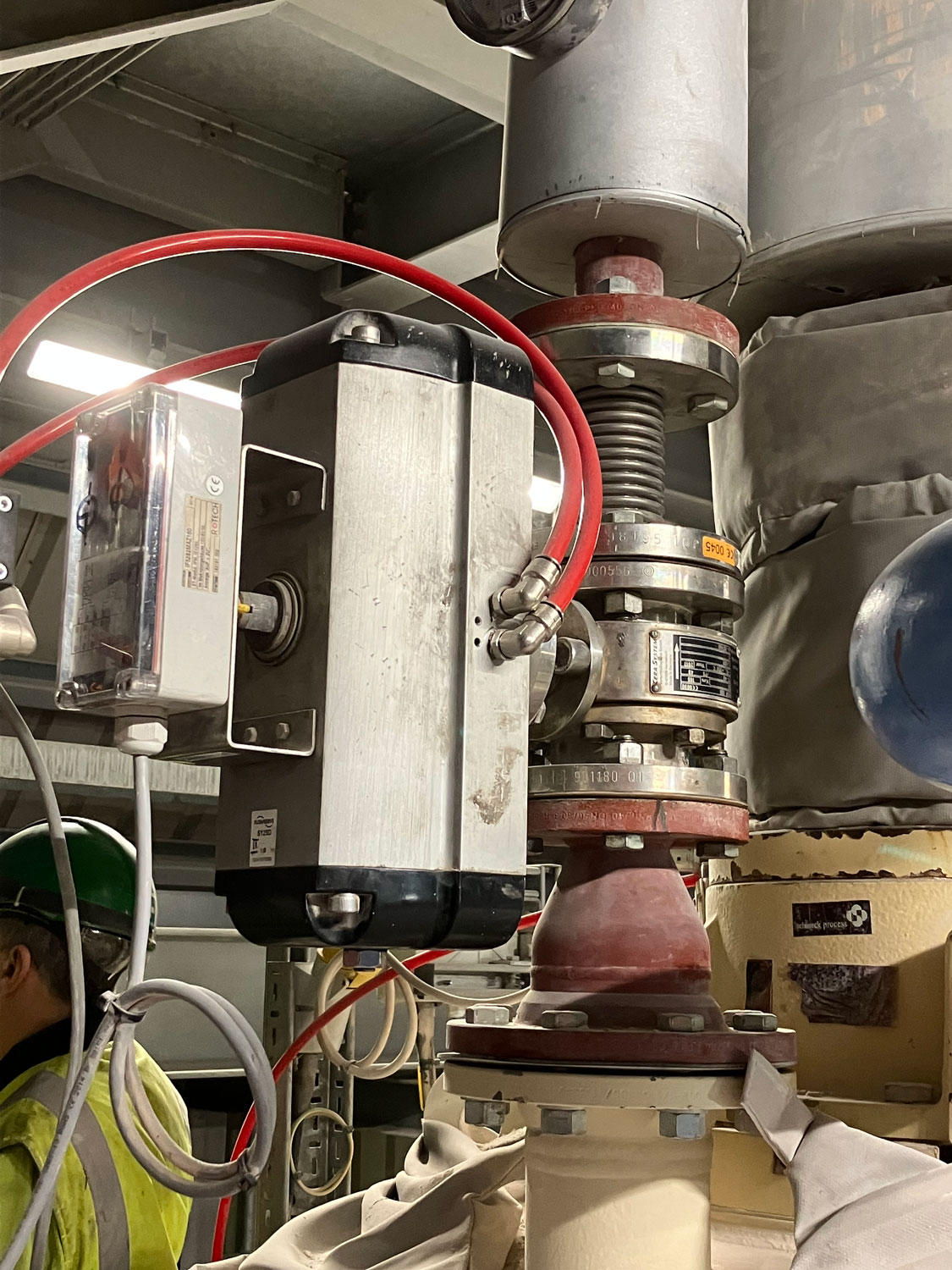

The new valve comes as a complete unit comprising valve, actuator, solenoid and limit switch box. Although the old and new valves have slightly different dimensions, simply adjusting the compensator above the valve enabled the new valve to be accommodated and made replacement relatively straightforward.

Original ceramic seated ball valve in-situ

Result

Firstly, the new valve immediately allowed the tanks to operate at full capacity, with no interruptions from emergency shutdowns.

Secondly, the design of the new valve’s sleeve means that maintenance is not only easier, quicker and more cost-effective, but it also becomes routine rather than a recurring emergency repair.

Thirdly, replacement lead times are reduced to just four weeks. So supply chain efficiency is significantly improved, and the customer is less exposed to lack of parts availability.

Lastly, the entire new valve unit (valve, actuator and accessories) costs just £2,215: representing a saving of more than two thirds on the old valve, and delivering immediate payback. A spare diaphragm for a valve overhaul is just £190.

Worn ball from the ceramic seated valves

In addition to the reduction in unit cost, the customer has made more savings through the prevention of unplanned shutdowns and downtime, and by reducing the time required for maintenance. The result is cost savings of £20,000 per valve.

With two valves per mill tank, and five other mill sites, the customer has huge potential for making further improvements in reliability and operational stability; for enhancing maintenance practices; and for achieving even greater cost reductions.