In this article

Wear Resistant Coatings Help Restore Pump Efficiency

Reducing food safety risks and extending life

Industry Sector:

Automotive

Application:

Process Water Pump

Actual Saving:

£19.680

Payback period:

1.5 years

Product/Service:

- Pump Repair and Overhaul

- Re-engineering

- Surface Coatings

Customer Benefits:

- Increased Efficiency

- Extended Component Life

- Reduced Energy Consumption

- Maximised Productivity

Castings, impellers and volutes wear due to corrosion, erosion, cavitation and mechanical damage and can significantly impact overall efficiency. But when your production schedules are tightly managed, any inefficiencies are magnified tenfold.

That’s precisely the problem a major UK automotive manufacturer was facing with a troublesome water process pump.

Challenge

The pump in question was inspected by ERIKS Engineering Team and found to be under-performing by at least 30% against the manufacturer’s original test data.

Dismantling of the unit revealed heavy corrosion of the pump, a worn, burred and imbalanced pump impeller, seized mechanical seal, and misalignment of the pump with the motor. In addition, the volute was cut-water worn, the bearings showed evidence of fretting and corrosion, and the motor was not inverter rated.

Solution

The damaged components were effectively and economically repaired using Henkel’s Loctite® Surface Engineering Products, minimising the risk of critical failure and downtime. Whilst also cutting energy consumption to reduce overall operational costs and carbon emissions.

After reassembling the pump ERIKS carried out a second performance test, with outstanding results. The remedial work had restored the pump to its original specification, increasing its efficiency by 30%.

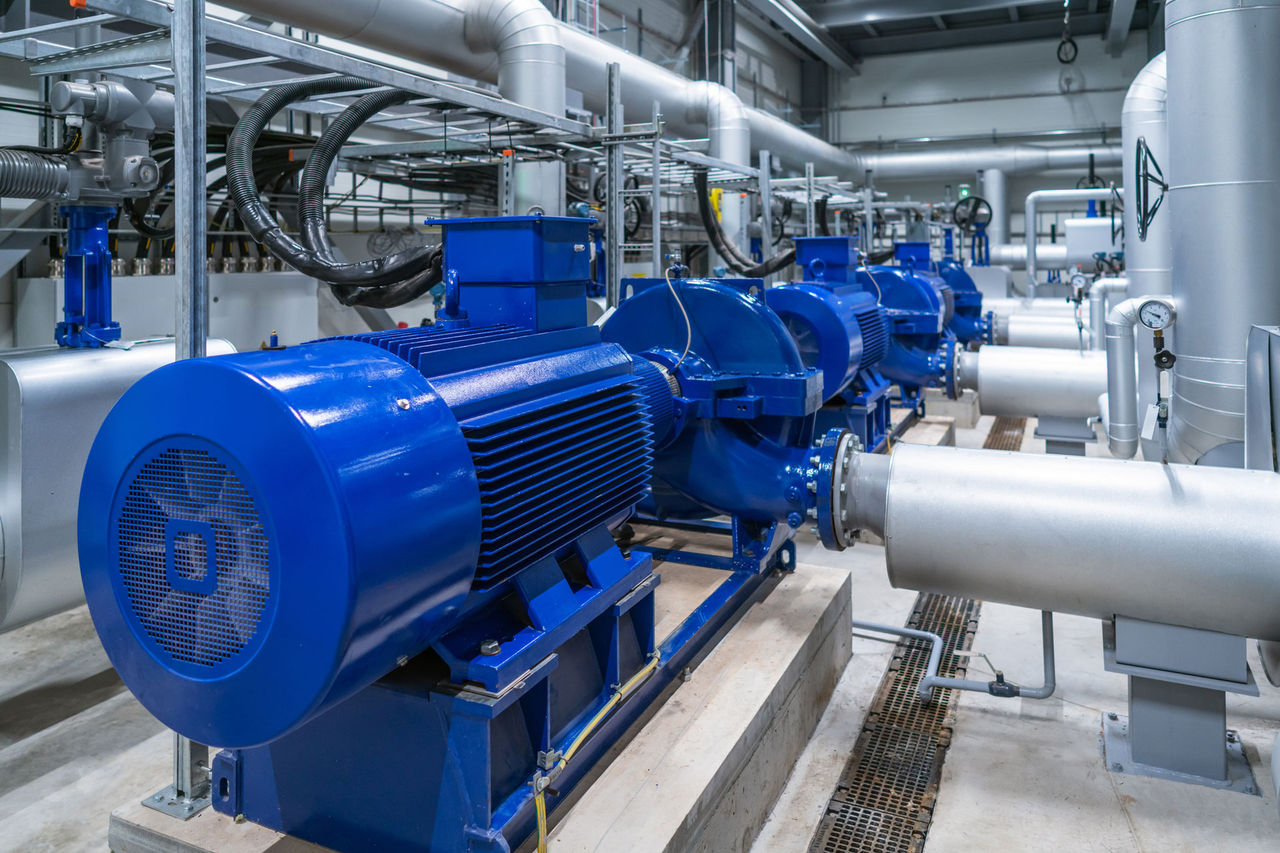

Applying wear resistant coatings to the internal components

Finished casing with wear resistant coating

Result

The repair cost was largely offset by a reduction in energy costs of £3,936 in the first year alone. CO2 emissions were reduced by 28 tonnes, and energy savings of 51.90 MWh will save energy costs over a five-year period totalling £19,680 – on one pump alone.

Needless to say, the manufacturer is now evaluating the potential energy savings that could result from more pumps receiving the Loctite® treatment from ERIKS.