In this article

20% of your MRO spend is wasted... Here's how to get it back

A major survey into the MRO supply chain has revealed that UK manufacturers are writing-off millions of pounds of stock every year. Yet saving up to 20% of MRO spending – while also increasing productivity and efficiency – is so simple, you don’t even have to leave your site.

Because, as the name suggests, the ERIKS OnSite specialist team comes to you.

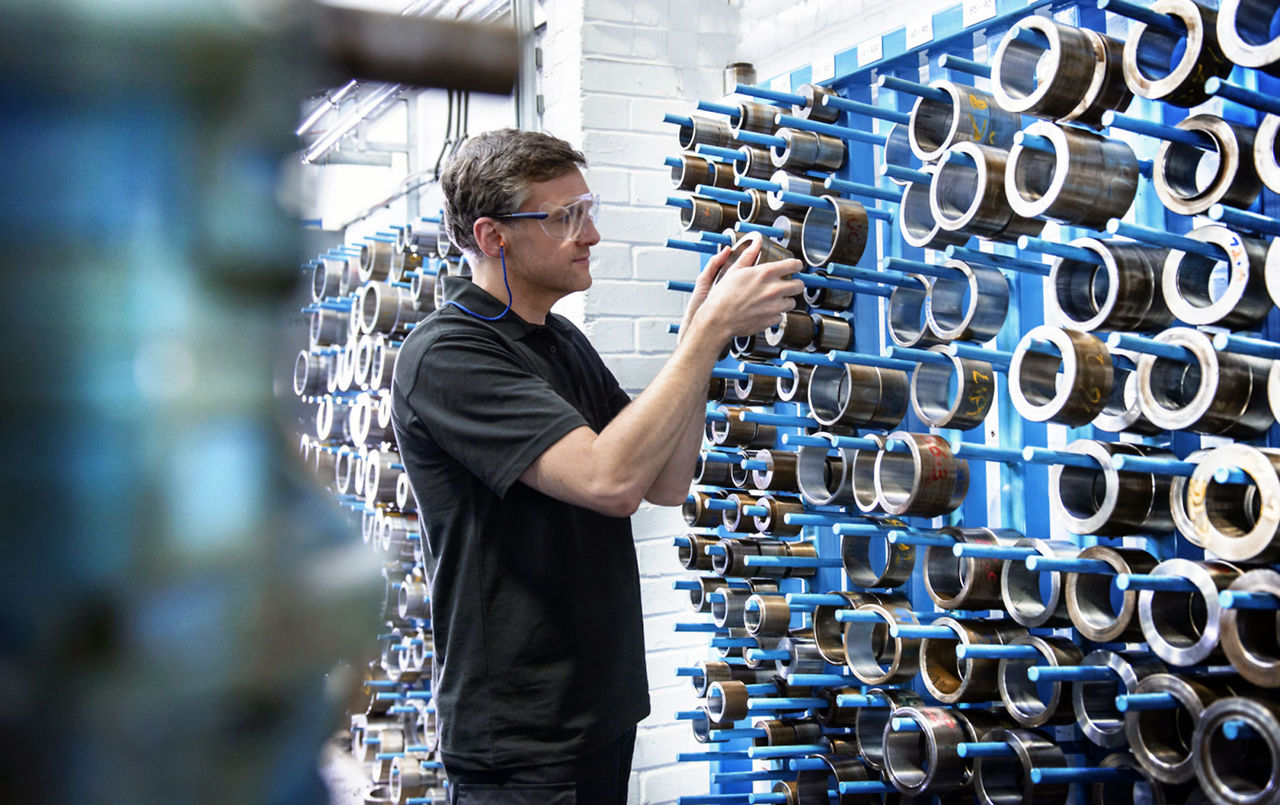

ERIKS OnSite is the integrated supply chain service, based on your site, that will maximise the performance of your engineering stores, using know-how in vendor-managed inventory, MRO procurement, inventory control and engineering stores management.

Plus the support of ERIKS’ major multinational supply chain, which helps to ensure continuity of supply and perfectly scheduled parts deliveries, even when unforeseen outside forces are causing disruption to other suppliers.

It’s something ERIKS has been doing for almost three decades, for numerous manufacturers in a wide range of industries throughout the UK and Ireland.

Smashing the window

One company making the most of ERIKS OnSite Services is SAI Automotive in Lichfield.

As a leading supplier to Jaguar Land Rover, the business manufactures door panels within a six-hour production window. Any longer, and their customer’s own production will be delayed at a cost of £30,000 - £80,000 per minute.

Clearly SAI Automotive can’t afford any hitches. And with ERIKS OnSite running their supply chain, they don’t have any. In fact, of over 500 items delivered in a given month, those recorded as ‘on time’ represented 91-96%.

More for less

Over the past decade, economic operating conditions in the wider world have led to manufacturers moving from a ‘just in time’ approach to ‘just in case’. This has led to more stockpiling of more parts – with more money lost in write-offs.

With ERIKS OnSite Services, on the other hand, you gain more control, more data insight and more efficient stores – all for lower cost. And you free-up your engineers to spend time doing what they do best, rather than wasting time finding and sourcing the parts they need.

To find out how and why manufacturers are wasting 20% of their MRO spend, and how you could buck the trend, visit ERIKS OnSite Services and download your copy of the MRO Supply Chain report.

Also, don’t forget to stay up to date with all things OnSite and follow our dedicated LinkedIn page.

For more information, contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #MRO #OnSiteSolutions #SupplyChain