In this article

How to pluck energy savings out of the air

Nothing concentrates the mind like rising energy prices. But if you’ve already taken all the obvious energy-saving steps you can, where will your next savings come from? Don’t worry if you can’t see them: they’re invisible. You’ll find them in your compressed air.

Six education

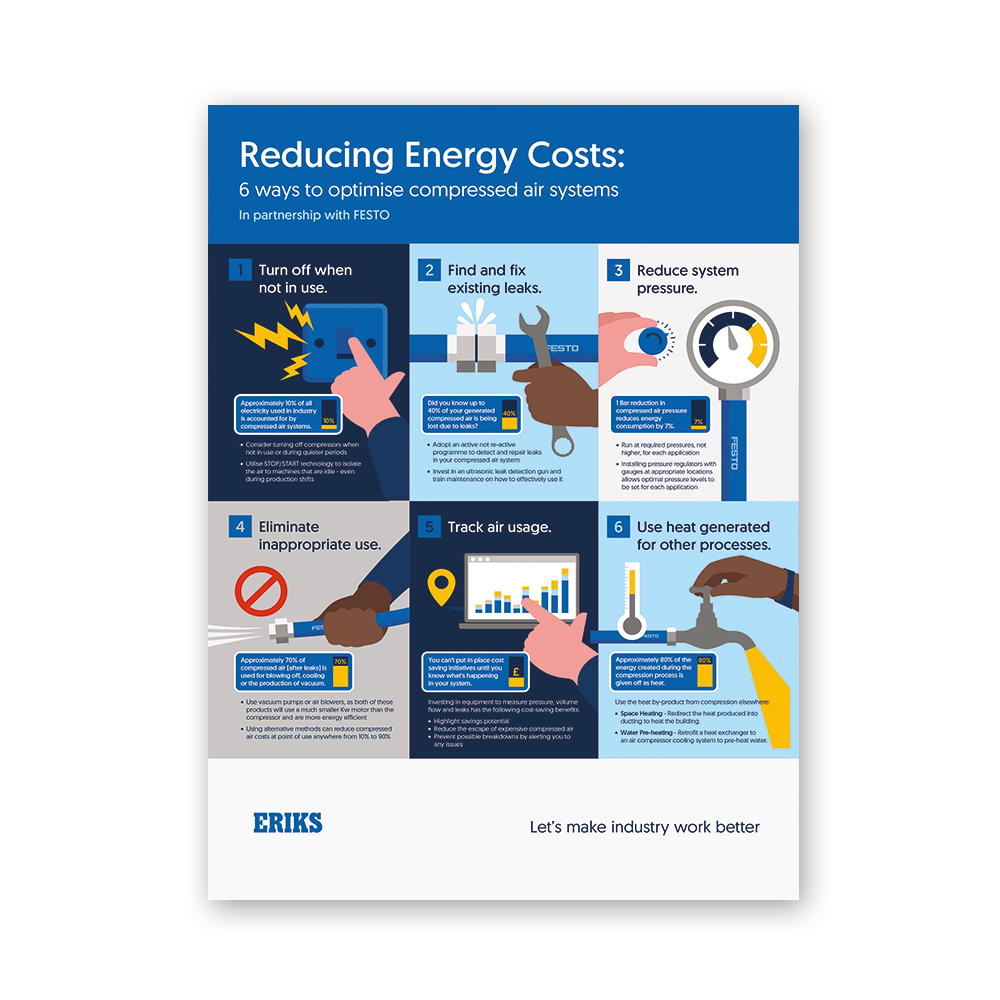

When something is so widely used in so many different ways as compressed air, it can be difficult to know where to start looking for savings. That’s why Festo – the experts in pneumatic control systems – have come up with the top six energy-saving tips for compressed air. And they start with the simplest of all: turn it off.

Because air is always available, many people think compressed air should be too. But why run a compressor 24/7, when compressed air will only be needed for a fraction of that time? Most compressed air systems only run at or near full capacity for up to 100 hours out of 168 in the working week.

By examining your shift patterns, and thinking about when you really need compressed air to be available, you should be able to identify many times when you can simply switch off your compressor and cut out the energy cost.

But remember if with your shifts you can’t turn off the compressor, but you can shut down a production line then don’t just turn off the electrical power to the line but also isolate the compressed air. Otherwise, compressed air production – and unnecessary energy use – carries on.

This one simple step could shrink your energy bills by up to 20%. But if you want it to be even easier to make savings, the MSE6-E2M unit from Festo will monitor compressed air usage at line and machine level, and automatically reduce the system pressure to 0 bar when production stops.

Pssst! You're leaking energy

Compressed air leaks aren’t obvious. Escaping air can’t be seen, and often can’t even be heard. Yet on average, systems lose up to 40% of generated compressed air through leakage. So fixing the leaks will quickly deliver real savings.

Most leaks are from badly installed or poor quality fittings, or poor quality tube. Even something as simple as using a proper tube cutter instead of a Stanley knife or similar will help to improve joints and prevent leaks. And using a high-quality tube with the right fitting – whether it’s plastic, brass or stainless steel – will make every connection even more leakproof.

For every pneumatic tube there’s a perfect Festo fitting – including widely-used and easy-to-install pneumatic push-in fittings. For the tubing itself, Festo PUN-H / PUN-H-Duo is the most popular. Made from polyurethane, it’s flexible, hydrolysis resistant, and FDA foodsafe approved.

If you’re not sure how to find your air leaks, ERIKS can provide an Air Leak Survey, and advice on the most effective Festo solutions to improve your system’s efficiency.

Take the pressure off

Dropping the pressure in your compressed air system is a sure-fire energy-saving measure.

Though most factories can operate efficiently at 5 bars, some applications require more. But the solution is not to boost pressure site-wide. Instead, optimise the pressure for individual applications in one of two ways.

Either install pressure regulators and gauges for every application, or a Festo Pressure Booster DPA where an application demands higher pressure. Then you can reduce the pressure for applications which don’t require higher pressure, and reduce your energy consumption by 7% for every 1 Bar reduction.

Is air the answer?

Around 70% of compressed air production (after leaks) is used for blowing off, cooling or producing a vacuum.

But it may not be the most cost-effective solution. An Air Blower or Vacuum Pump, for example, will use a smaller motor than a compressor, and therefore use less energy to do the same job.

However, when compressed air is the answer, you can still enhance its efficiency. A specialised accessory like the Venturi air nozzle from Festo, used for blowing off, drying or cleaning, can cut compressed air costs at point-of-use by 10-90%.

Knowledge is (less) power

Only when you know and understand how your compressed air system is operating, can you do whatever’s necessary to make it more energy-efficient.

The Festo Flow Sensor SFAM will deliver continuous absolute flow rate information, as well as cumulative values based on air consumption measurements. Any increase in flow rate will be your air leak alarm bell, enabling you to fix minor issues quickly, before they become major, power-hungry problems.

The hot tip

Compressed air has many uses and, as you can see from the ideas above, offers many ways to save you energy. But there’s one more energy-saving tip which you may not have heard of: using compressed air to heat your buildings.

Around 80% of the energy created by compressing air is given off as heat. Rather than letting this go to waste, it can be redirected into ducting to provide heating, or be used to pre-heat water via a heat exchanger retrofitted to the air compressor cooling system.

It’s just one more way you can pluck energy savings out of the air. Why not ask ERIKS for more advice and expert help? You can trust them not to talk a load of hot air.

Get involved...

For more information on any of the Festo solutions or ERIKS services mentioned above, simply complete

the Request For Quote form on our FESTO Top Tips Page.

While you're there, why not download our 6 ways to optimise compressed air systems?

For more information on any of the Festo solutions or ERIKS services mentioned above, simply complete the Request For Quote form on our FESTO Top Tips Page.

#Festo #ERIKS #LetsMakeIndustryWorkBetter #CompressedAir #EnergySavings