In this article

Will you be a loser in the HV motor lottery?

What are you prepared to gamble on your HV motors’ reliability? The losses incurred through months of downtime if they let you down? The costs of extracting an asset for an unnecessary overhaul? Or would you rather bet on sophisticated testing, comprehensive monitoring, and engineering expertise for your peace of mind? That’s what one construction materials manufacturer did, by putting everything on ERIKS to win.

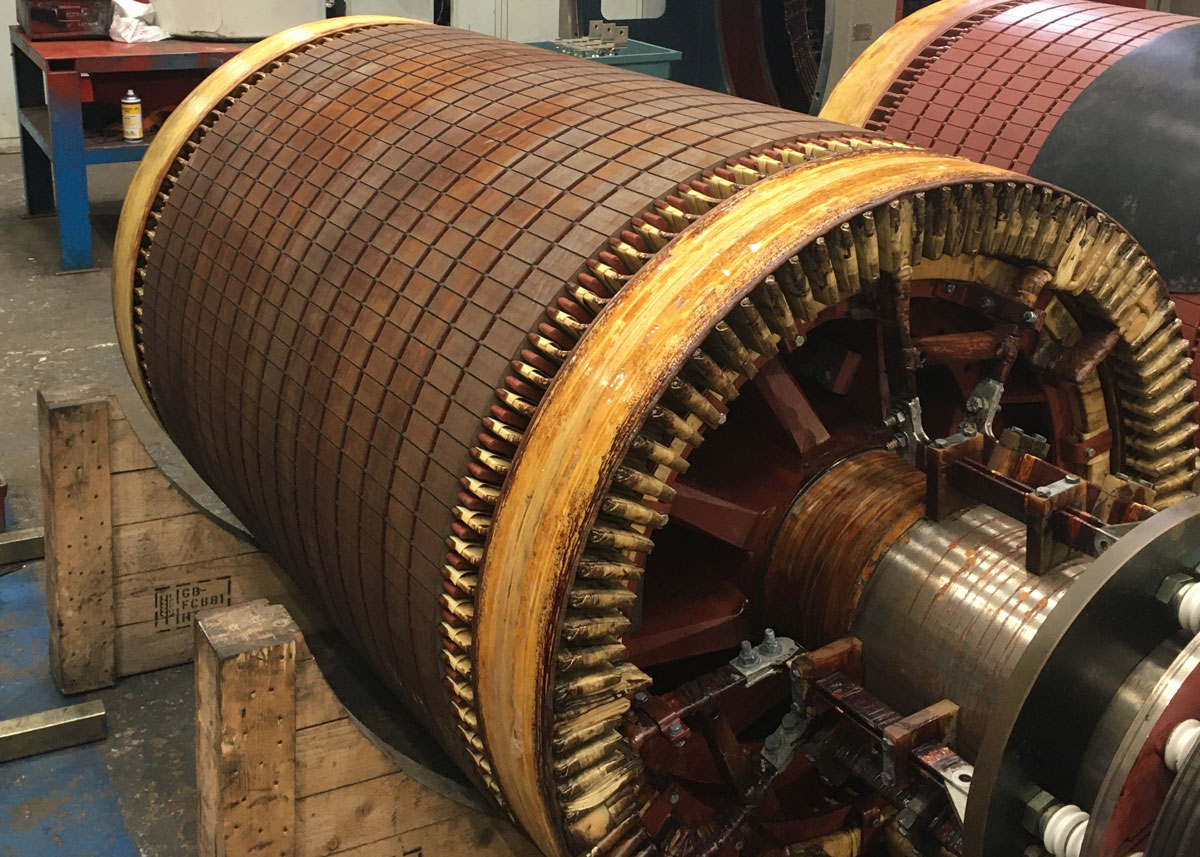

In a recent competitive tendering process for HV motor maintenance and repair, ERIKS won the business through a unique combination of three key strengths. Not just expertise in maintaining HV motors. Not just unrivalled experience and resources. It was both those, plus Partial Discharge (PD) and Tan Delta testing capabilities [see box-out].

The customer not only gets the reassurance of optimised reliability, through expert maintenance of their high voltage critical assets. They also avoid the expense of extracting a healthy motor simply because it’s on the rota for maintenance. And the potential cost of overlooking a failing motor just because ‘it’s not its turn.’

For such a critical asset – where reliability is crucial – making a wrong call like this could be the difference between cost-savings and catastrophe.

Test-in or takeaway?

An inflexible maintenance schedule is a lottery with the odds stacked against you.

If you have two duty motors and two standbys, and the schedule says Motor 2 is due for testing, it has to be tested. But until it’s extracted and inspected, most motor repairers won’t know if it actually needs work. With four motors that could need attention, the odds don’t look good.

Removing an HV motor for testing is costly. And if the tests reveal it’s in good condition, it’s money lost you can never get back. So one of the major cost- and time-saving benefits ERIKS offers is the capability for onsite PD and Tan Delta testing. This does more than tip the odds in your favour. It actually guarantees a win.

Firstly, you’ll never remove a reliable motor in good repair simply because it’s scheduled. And secondly, you can identify which motor needs the most urgent attention, before a potential failure turns into downtime.

'Plan for what's difficult - while it's easy'

Chinese army general Sun Tzu wasn’t thinking about HV motors, but he knew the benefits of being prepared.

If you have a planned shutdown scheduled for August, Sun Tzu would tell you to have ERIKS test your motors on-site in April. This will identify any motors which are degrading and need attention, before they let you down. You can prepare while it’s easy for what’s difficult: extracting them. Then when shutdown comes, you can remove them to the workshop for maintenance.

With your standby motors also tested in advance (and overhauled if necessary) you can be sure they will be ready to swap-out when the time comes.

Be a trendsetter

ERIKS’ regular on-site testing of your HV assets stacks the maintenance lottery odds even more in your favour.

Repeating the tests regularly – at least once a year – gives you more than a snapshot of your motors’ condition and reliability. It paints a complete picture. This enables ERIKS’ engineers to set a baseline, identify trends, and determine any rate of deterioration. Which means you can then focus planned maintenance on the motors which really need it.

Just one day’s on-site testing of your HV motors could save you as much as 12 weeks’ downtime. So why risk losing the motors maintenance lottery? Contact your usual ERIKS representative and win the biggest prize of all: reliability of your motors.

Testing, testing, one, two...

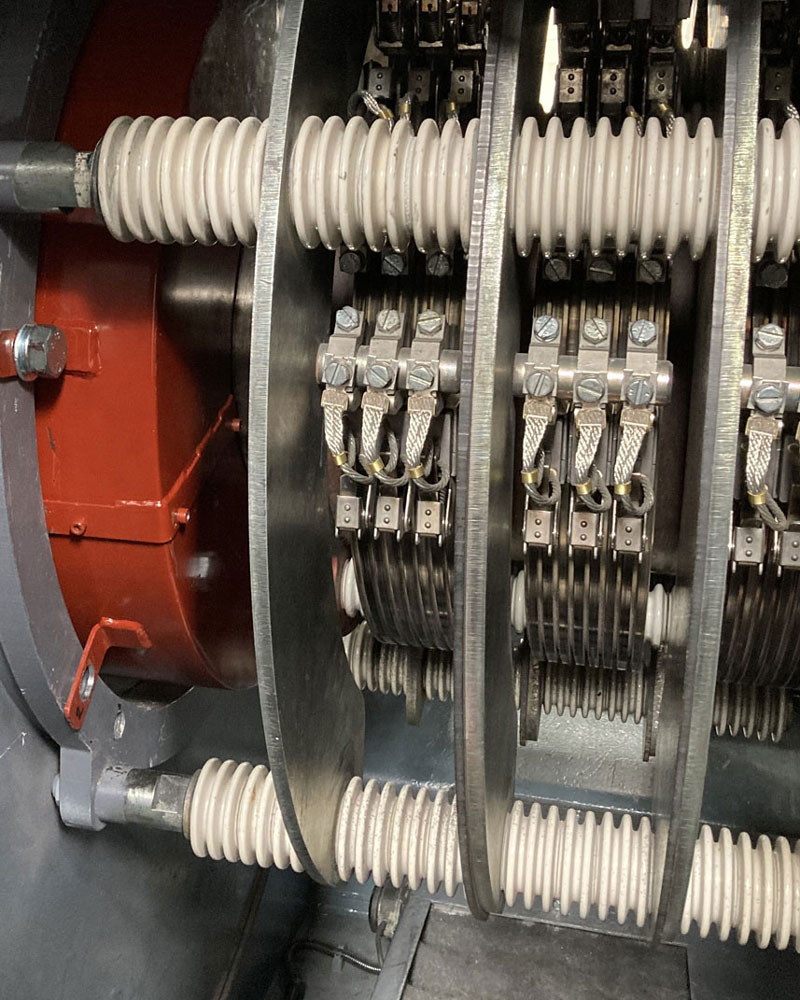

Partial Discharge (PD) testing checks for electrical discharge or spark, which takes place across a void or gap in insulation between two electrodes. Voids occur inevitably in HV windings. PD can accelerate damage to the insulation, which will ultimately cause the windings to fail – usually through a breakdown to earth.

Tan Delta testing indicates leakage of electrical current to ground, which depends on the condition of the machine insulation system. When the insulation has sufficiently decayed and the discharge levels and/or leakage currents are high enough, the winding will fail – also usually through a breakdown to ground. Repeated tests over time enable plotting of Tan Delta curves to identify deterioration of the winding insulation.

For more information on HV Motor solutions and to get in touch with one of our ERIKS Motor Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #HVMotors #Reliability #Monitoring #Engineering