In this article

Keeping it clean: ERIKS breathes new life into Hospital AHUs

In a clinical environment, air quality is critical - not just for comfort, but for patient safety. Nowhere is this more important than in operating theatres, where airflow must be tightly regulated to meet compliance requirements and prevent contamination.

At the heart of these systems are Air Handling Units (AHUs), that require efficient Laminar Air Flow (LAF) to be compliant with operating theatre regulations (HTM 03-01) that state a minimum of 25+ air changes per hour (ACH) must be achieved.

But over time, even well-maintained systems degrade. Belt-driven fans begin to slip. Pulleys wear down. Motors lose efficiency. Should airflow drop down below required levels, patient outcomes and operational continuity are put at serious risk.

More pressure, more problems

That was exactly the challenge faced by one busy NHS hospital. Increased theatre use had added extra strain on their ageing AHUs. Despite ongoing maintenance, airflow performance was slipping – raising red flags about compliance, energy use, and long-term reliability.

Faced with tight budgets, limited shutdown windows, and increasing performance pressures, the hospital sought a partner capable of delivering fast, effective results with minimal disruption – and found exactly what they needed in ERIKS.

A precise, practical approach

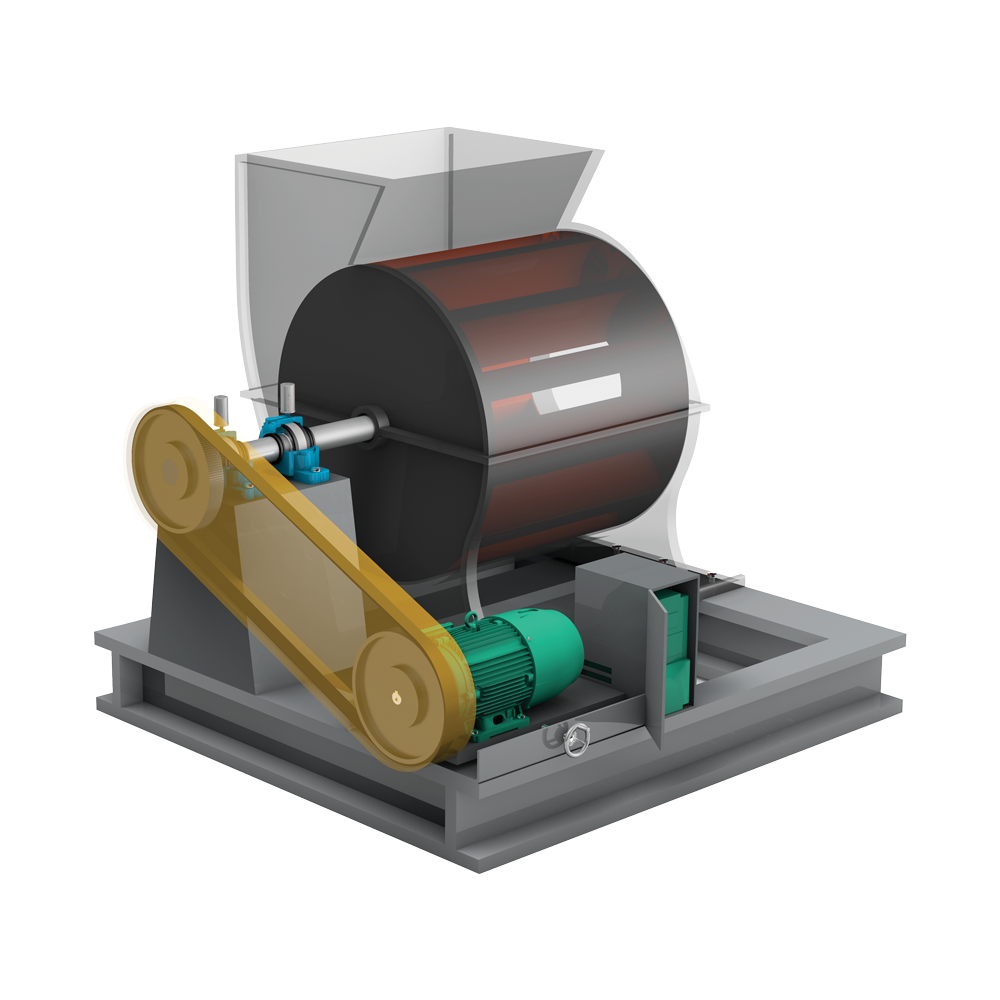

ERIKS began with a detailed on-site assessment of the AHUs, looking beyond surface-level symptoms to diagnose the true performance bottlenecks. While worn belts were a clear issue, the team found deeper inefficiencies in pulley wear, drive alignment, and an ageing motor that no longer met energy standards.

Belts are a standard part of the upgrade, and as part of our thorough assessment, we also include the condition of the pulleys. While often overlooked, they are critical to overall system efficiency.

Over time, pulleys can show wear; they will usually still perform but not at optimum efficiency and no longer transmit power effectively. Worn pulleys can cause belt slippage, leading to belt overheating and premature wear.

Worn grooves or uneven surfaces on the pulleys also create imbalance, increasing vibration, noise, and potential damage to connected machinery, such as bearings. This increases load and stress, causing bearings to fail prematurely.

To restore the system’s capacity, ERIKS upgraded the belt drive using a high-spec Fenner® belt and carefully selected matching pulleys, ensuring consistent tension and efficient power transfer.

New Taper Lock® bushes ensured a precise, secure fit and enabled quick future replacements.

A smarter, cleaner motor

Rather than overhauling the worn motor, ERIKS recommended a new IE4-rated energy-efficient model. Though an overhaul was technically possible, the increased demands of the theatre meant that an upgrade would offer greater value in the long run – lowering energy use and improving reliability without compromise.

The result was an immediate improvement in fan performance and overall airflow, giving hospital teams renewed confidence in their compliance and operational resilience.

Balance and alignment

Once the drive system and motor were replaced, ERIKS turned their attention to fan balancing – a step that is often underestimated when it comes to restoring AHU performance.

Imbalances can introduce vibrations, raise noise levels, and accelerate wear across the entire system. ERIKS’ specialists rebalanced the fan on-site, then completed a full laser alignment of the drive system to ensure optimal performance and long-term durability.

The entire process, from teardown to commissioning, was handled by ERIKS’ field services team. Their familiarity with critical NHS infrastructure meant the work was carried out efficiently and safely, with minimal disruption to theatre operations.

Compliance and resilience

The result? Improved airflow, lower energy bills, more reliable theatre operation, and, most importantly, confidence that the hospital can meet ventilation compliance demands well into the future.

Standardisation and smarter component selection also mean that future maintenance is simpler and faster. With fewer breakdown risks and greater overall efficiency, the hospital’s AHUs are now better prepared for whatever lies ahead – without costly overhauls or extended downtime.

As the hospital’s facilities team commented: “ERIKS made the whole process seamless. From diagnosis to installation, everything was clearly explained and professionally delivered. The improvement in airflow was immediate.”

With deep sector experience and a hands-on, engineering-led approach, ERIKS continues to support critical infrastructure across the NHS – helping hospitals to stay compliant, energy-efficient, and always ready to perform.

For more information on Hospital Infrastructure, or get in touch with your local ERIKS Service Centre who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Infrastructure #Hospitals #AHUs #Compliance #EnergySavings

Sign-up for Support for your Industry:

A Hospital Team member will review your enquiry and respond promptly.