In this article

Only one bearing beats the SKF Explorer SRB

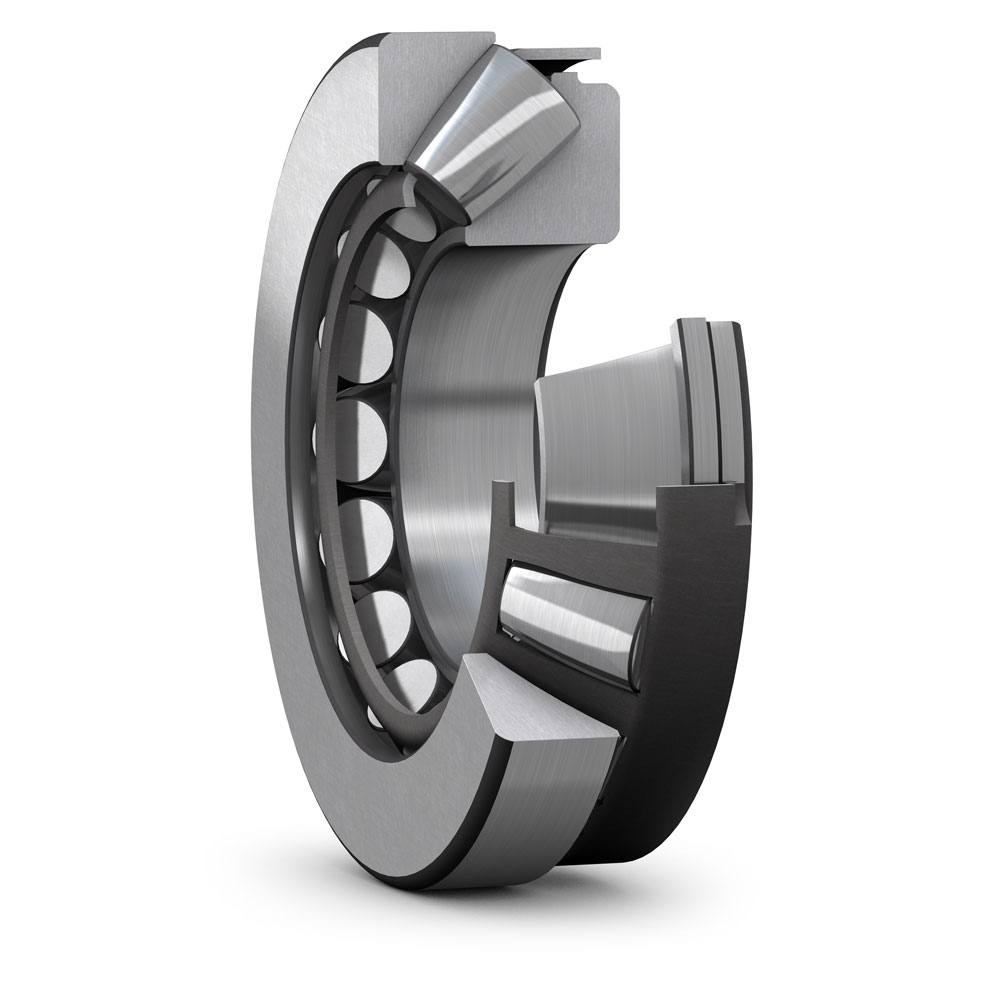

When the SKF Explorer self-aligning roller bearing was launched almost 25 years ago, it was ground-breaking. Nothing could match its load-carrying capacity and extended service life. But now there’s a bearing that performs even better: the upgraded SKF Explorer.

With improved wear resistance and extended failure mode, it provides significantly longer service life, increased equipment uptime – and the virtual elimination of unplanned downtime.

In many of today’s harshest and most challenging operating environments, bearing failure is an ever-present threat. Severe contamination or poor lubrication can quickly lead to a failed bearing, an equipment shutdown, and extensive – and expensive – downtime. In these conditions, the original SKF Explorer self-aligning roller bearing offers high reliability.

Now the good news is that the upgraded SKF Explorer offers even greater reliability, thanks to an improved heat treatment process which delivers a range of bearing performance benefits.

The heat is on

Engineers and scientists worked together to develop the original SKF Explorer range.

Blending their knowledge of metals, engineering design and industrial equipment operating conditions, they created a bearing with a superior performance certified by two of the leading certification bodies (Germanischer Lloyd and Det Norske Veritas).

Utilising an extremely clean and homogenous bearing steel, processed with a unique heat treatment, the pioneering team produced a bearing material with exceptional strength and durability, and the optimal combination of hardness and dimensional stability. Then they incorporated the achievements of the scientists with the expertise of the engineers, to produce a bearing concept with improved surface structures and refined internal geometry tolerances.

The result was a bearing specification which couldn’t be improved on. Until now.

Hard and tough – just like the conditions

Metals and mining, mineral and cement processing, wind power and marine are typical of the industry sectors where contamination can be high, lubricating conditions poor, and where ordinary bearings struggle. They’re also the sectors where the upgraded SKF Explorer self-aligning roller bearing comes into its own.

The unique, patented SKF Xbit-II steel rings have undergone an improved heat treatment. While maintaining their toughness and enhancing their wear resistance, this has increased their hardness by up to 2 HRC (depending on bearing size). The outcome is longer uptime for virtually any application where reliability and long service life are key.

The same treatment also gives the bearings excellent crack resistance. This means minor faults take longer to turn into major ones, and there’s more time from the first signs of damage until the bearing becomes unserviceable.

For medium-size and large bearings used in process equipment, that gives more time to prepare for repairs. So it’s easier to schedule maintenance around planned shutdowns, and virtually eliminates unplanned downtime and associated additional costs.

Leading a double life

Even with poor lubrication and in contaminated conditions, the upgraded SKF Explorer bearings outperform the earlier version. Independent and SKF testing has shown that customers can expect the bearings to last up to twice as long.

On medium and large bearings, the tests showed that the time from initial spalling to through-fracture is extended. The flange strength is also greater, so in tests the upgraded SKF Explorer still ran twice as long after the flanges fractured, and only developed spalls.

Of course, bearings in process equipment are never deliberately run to through-fracture, but the tests give real reassurance that once damage has been detected there’s time to plan, order parts and prepare for a shutdown with less downtime.

For sealed SKF spherical roller bearings, the figures are even more impressive. By keeping out contaminants, they have been shown to last at least three times as long as open bearings.

More life, less…

…friction

SKF Explorer spherical roller bearings have self-guided rollers for excellent friction control. This can increase machine efficiency, or reduce the frequency of relubrication.

…CO2

Lower-friction bearings mean greater energy efficiency in use, which means fewer CO2 emissions.

…waste

Many SKF Explorer bearings can be remanufactured, potentially reducing their carbon footprint by up to 90% compared to buying new.

With so much to gain (like wear resistance and service life), and so much to lose (all the bad things) isn’t it time you explored the upgraded SKF Explorer self-aligning roller bearings?

For more information on Bearing Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SKF #ERIKS #LetsMakeIndustryWorkBetter #Bearings #SphericalRollerBearings #SKFExplorer