In this article

When Warmth is Your Best Ally: Unlocking the Magic of Bearing Heaters for Optimal Installation

There's nothing more frustrating than an improperly fitted bearing which can wreak havoc on machinery, causing downtime and skyrocketing maintenance costs. Ensuring their proper installation is a non-negotiable part of the equation, and that's precisely where bearing heaters come into play. So why should you care about this not-so-secret weapon? Well, let's delve in.

What Are Bearing Heaters Anyway?

Bearing heaters are specialised equipment designed to heat bearings and other ring-shaped metal parts. By increasing the temperature of the bearing, these devices expand its inner ring, making it easier to install onto the shaft. Forget the old-school methods of using blowtorches or oil baths; bearing heaters provide a more uniform, controlled, and, above all, safer way to heat your bearings.

First off, using a bearing heater makes the whole installation process a walk in the park. By expanding the inner ring uniformly, the bearing slips onto the shaft like a charm. This not only reduces the time spent on installation but also eliminates the risk of workpiece microstructure damage.

You might be asking, why does all this matter? Well, when a bearing is improperly installed, it can reduce the lifespan of both the bearing and the machinery it's a part of. But with bearing heaters, you're looking at a perfectly fitted, stress-free bearing every time.

Turning Up the Heat: How Bearing Heaters Improve Productivity

If we're talking about improving productivity, bearing heaters are a dream come true. For starters, the time saved in the installation process can be channelled into other critical tasks, which can speed up project timelines significantly.

Additionally, a well-fitted bearing performs optimally, ensuring that machinery runs smoothly. This, in turn, results in less unplanned maintenance work, which we all know is the bane of productivity. In a nutshell, bearing heaters take productivity up a notch by making the installation quicker and more efficient.

Let's not forget the advantage of repeatability. With bearing heaters, the uniform heating ensures that each installation is as perfect as the last, ensuring a consistent level of quality and reducing the risk of future machinery issues. Consistency is key to productivity, and bearing heaters deliver it in spades.

Safety First: The Undeniable Perks of Increased Safety

When it comes to industrial processes, there's nothing more paramount than safety, and bearing heaters excel in this department. Traditional methods like oil baths or blowtorches are not only messy but can also be hazardous, posing a risk of burns or even fire.

Bearing heaters, on the other hand, are built with safety features such as temperature controllers and timers, ensuring that the heating process is safe and controlled. This minimises the risk of accidents, providing a safer environment for your team.

Moreover, a safely installed bearing is a reliable one. A reliable bearing minimises the risks of machinery malfunction, which could otherwise result in costly downtime or, worse, workplace accidents. Statistics report you are 9x more likely to have an accident in a downtime situation. Hence, increased safety is not just about immediate risks but also about ensuring long-term operational integrity.

For the Long Haul: Ensuring a Longer Product Lifespan

A well-installed bearing isn't just good for immediate productivity; it's an investment in the future. By eliminating fitting stresses and workpiece damage, bearing heaters extend the lifespan of your bearings significantly.

More life from your bearings means less frequent replacements, which not only saves money but also reduces waste. Given the increasing focus on sustainability and waste reduction in engineering practices, this is a win-win situation.

Lastly, longer product lifespan equals less frequent machinery breakdowns, which, in turn, results in lower maintenance costs over the long term. The benefits of using bearing heaters thus ripple across the operational timeline, proving their worth as a long-term asset for any engineering endeavour.

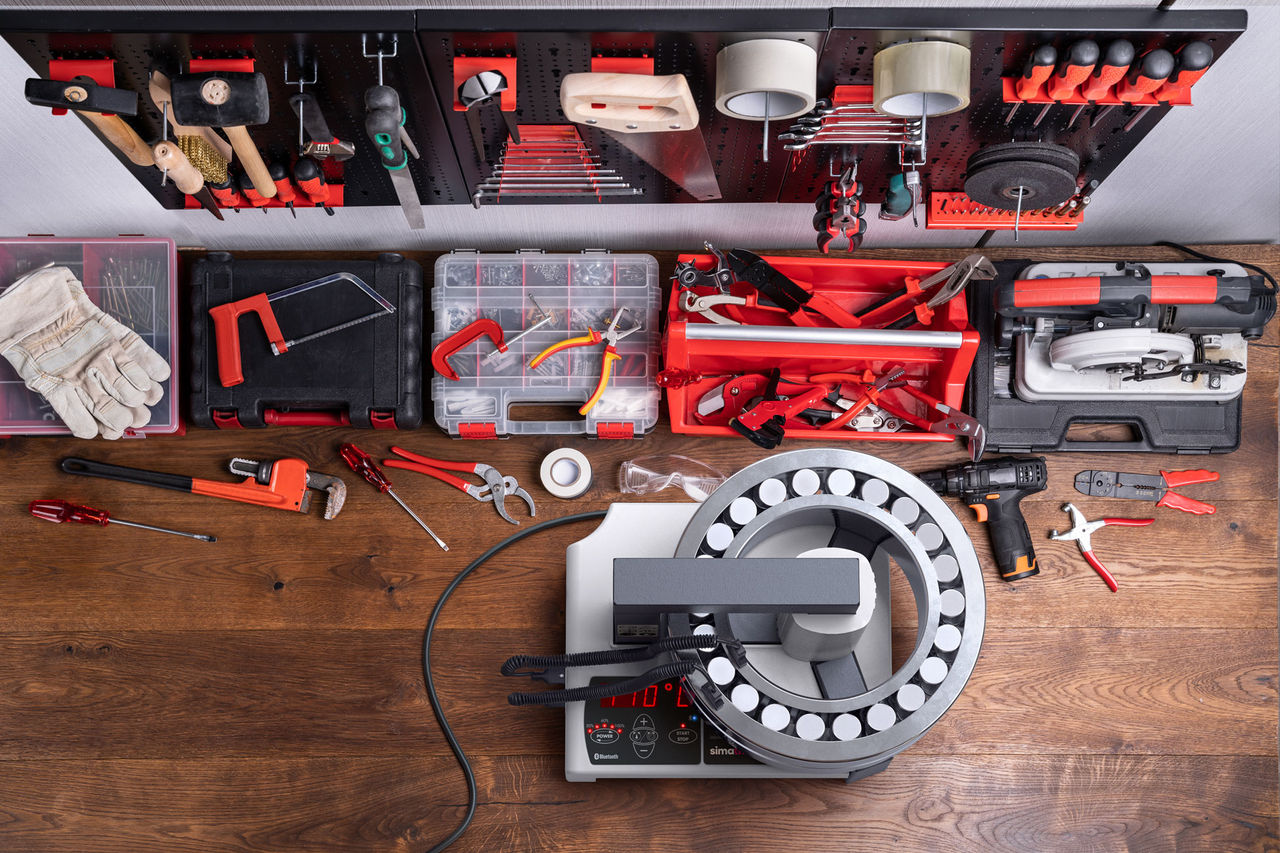

Product Spotlight: Meet the Simatec IH 045, the Ultimate Game-Changer in Bearing Heaters

So, you’ve just read all about the benefits of using bearing heaters, right? Improving productivity, increasing safety, and ensuring a longer product lifespan – the trifecta we all aim for. Now, how would you feel if I told you that there's a product out there that not only encapsulates all these benefits but takes them to an entirely new level? Allow me to introduce you to the Simatec IH 045, a groundbreaking induction heater that’s a bona fide revolution in the world of bearing installation.

Your Dream Heater, Now App-Controlled!

Yes, you read that right. The IH 045 is the world's first controllable induction heater equipped with an app – the "simatec World of Maintenance" app to be precise. Talk about convenience! Control your heater remotely and adjust settings without even being in the same room. And guess what? It's compatible with voltages of 100, 115, and 230 V. Flexibility at its finest.

Efficiency That Speaks Volumes

Size doesn’t always matter, at least when it comes to bearing heaters. Despite being the smallest and fastest device in its performance class, the IH 045 punches well above its weight. Thanks to its external induction coil, this unit works with remarkable efficiency. You can even adjust the power in eight stages to tailor it to your specific needs.

Adaptability Meets Performance

What sets the IH 045 apart is its sheer adaptability. Designed for both small and medium-sized workpieces weighing up to 45kg, it accommodates inner diameters from 20 to 310 mm. And with its extendable bearing support arms, you're looking at one of the most versatile bearing heaters on the market.

Time and Energy, Saved!

A 28kg bearing heated from 20°C to 110°C in just 20 minutes. Let that sink in. In an industry where every minute counts, the IH 045 is your ticket to improved productivity and energy efficiency. Oh, and it automatically demagnetises the bearing too!

Why Simatec IH 045 Should Be Your Next Purchase

- Connectivity: Seamless interaction with the "simatec World of Maintenance" app.

- Remote Control: Control the heater from wherever you are.

- 8-stage Power Consumption: Customise the heating process with adjustable power levels.

- Versatility: Perfect for rolling bearings up to 45 kg and inner diameters of 20 to 310 mm.

- Energy Efficiency: Supplied with three yokes and the smallest external induction coil for maximised efficiency.

- Compact Design: Including the yokes, it weighs just 17 kg.

- 3-Year Manufacturer Warranty: Quality guaranteed.

This isn’t just a product; it's an investment in elevating your bearing installation process to unparalleled heights. And to seal the deal, the IH 045 comes with a 3-year manufacturer warranty. When it comes to bearing heaters, this is as good as it gets.

Don't let this opportunity pass you by...

Make the Simatec IH 045 a cornerstone of your engineering toolkit today!

#simatec #simatherm #ERIKS #LetsMakeIndustryWorkBetter #BearingHeaters