Engineering Support for the UK Water Sector with ERIKS

ERIKS partners with major UK water companies to deliver responsive engineering solutions that reduce unplanned downtime and improve operational efficiency.

Why work with ERIKS for Water and Wastewater?

ERIKS is a trusted partner to the UK water and wastewater industry, offering expert engineering, maintenance, and supply chain solutions designed to reduce pollution risk, extend asset life, and boost energy efficiency.

ERIKS helps tackle the challenges of ageing infrastructure while enabling smarter, faster upgrades with minimal downtime. Whether you're looking to prevent unplanned pollution events, improve reliability, or hit net-zero targets, ERIKS delivers measurable results through tailored, end-to-end support.

- Pollution prevention and reliability support

Condition monitoring, rapid onsite repairs, and predictive maintenance reduce environmental risk and regulatory pressure. - Custom engineering with fast turnaround

Bespoke solutions built from standard, off-the-shelf components shorten lead times and simplify integration. - Energy-efficient upgrades

IE4 motors, pump optimisations, and drive retrofits deliver fast ROI and help meet sustainability and carbon-reduction goals.

ERIKS and the Water and Wastewater Industry

Scaleable "Plug and play" clarifier upgrade

Ageing clarifier drive systems can put wastewater treatment performance and compliance at serious risk. Frequent failures, costly downtime, and bespoke parts create ongoing headaches for utilities.

ERIKS provides a scalable, plug-and-play clarifier upgrade with integrated planetary gearmotor and variable speed drive technology – designed for high torque, low-speed performance with minimal maintenance. Standardised, adaptable, and installed in a single day, this solution helps water companies cut costs, improve efficiency, and future-proof clarifier operations.

Energy Management through Motor Re-Engineering

Running older motors to failure may seem cost-effective, but it often results in higher energy bills, carbon emissions, and unplanned disruption. ERIKS helps water utilities unlock major savings through energy-efficient motor upgrades that deliver measurable lifetime benefits.

By replacing outdated aerator paddle motors with IE4 high-efficiency alternatives, we cut energy consumption, carbon footprint, and total cost of ownership – while improving reliability and reducing downtime. With a proven track record of fast installation, regulatory compliance, and long-term savings, ERIKS enables utilities to plan smarter today for a more sustainable tomorrow.

Bridging the Gap

Wastewater treatment plants face growing challenges from outdated settlement and storm tank drive systems prone to frequent breakdowns, high maintenance, and safety risks.

ERIKS partners with utilities to design and install robust, low-maintenance drive solutions using Fenner Cyclo gearmotors, Timken bearings, and automated lubrication systems. Our upgrades not only enhance reliability and safety, but also create standardised, interchangeable systems across multiple tanks – simplifying servicing, reducing downtime, and improving resilience in harsh conditions. With ERIKS, water companies can bridge the gap between ageing assets and future-proofed infrastructure.

Every Drop Counts: Water Industry Solutions Brochure

Water is a limited resource – but the pressures on the industry are anything but. From tougher regulation and environmental targets to ageing infrastructure and increasing public scrutiny, water companies face rising demands with fewer resources.

Why chose ERIKS?

- Decades of sector expertise and trusted network agreements

- Susitainable MRO supply and repair solutions

- Insight and foresight to help your facilities operate at peak performance

- National reach, rapid response

- Dedicated in-house application engineers

Identifying Unidentified Repeated Failures

Repeated pump failures can drain capital and cripple wastewater operations if the real problem remains hidden.

At a major UK sewage treatment plant, years of costly repairs to low lift pumps failed to solve the underlying issue – until ERIKS stepped in with digital reliability services and online vibration monitoring. By installing wireless Bluetooth sensors and applying automated analysis, our engineers quickly pinpointed the true root cause – a simple installation fault that traditional maintenance had missed.

The result? An immediate payback, over £238,000 in savings, improved uptime, and future-proofed insight into asset health. With ERIKS, water utilities can move from reactive firefighting to data-driven maintenance strategies that protect assets, budgets, and the environment.

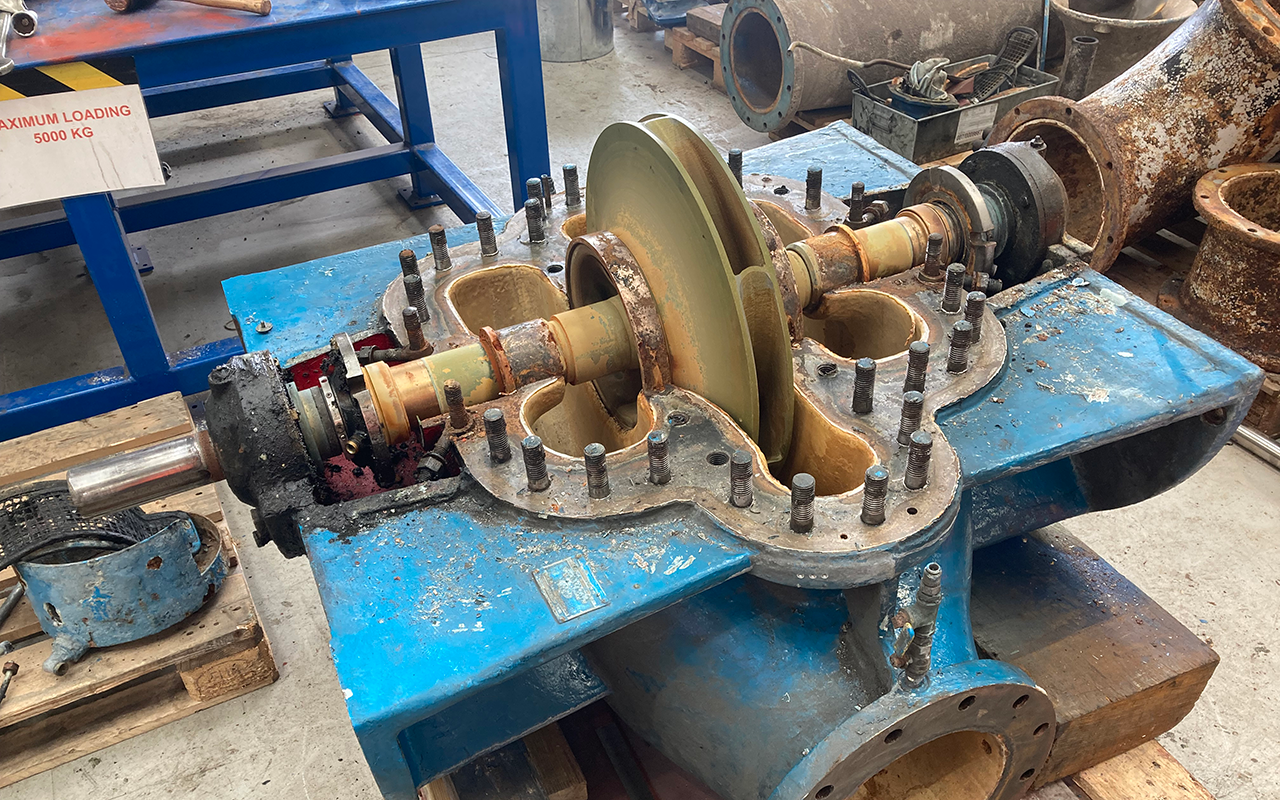

Priority One Repairs That Kept Water Flowing

When critical pumps fail, there’s no time to wait for lengthy quotations or delays – water supply and industrial operations depend on immediate action.

At a major water supply works in the South of England, ageing slip ring motors and decades of reactive maintenance left high-lift pumps at serious risk of failure, threatening both Southampton’s drinking water supply and a large local refinery.

ERIKS stepped in with Priority One repairs, delivering rapid removal, overhaul, and return-to-service of pumps and motors. With full refurbishment, precision testing, and fast turnaround, ERIKS ensured uninterrupted water flow, avoided costly downtime, and restored long-term pump performance.

When 'Right First Time' is The Only Option

For water authorities, downtime on critical assets like river intake pumps can mean lost productivity, rising costs, and reputational risk.

ERIKS helps utilities reduce maintenance demands, streamline spares management, and improve pump reliability through advanced repair and engineering services. By combining 3D scanning, reverse engineering, and specialist power transmission expertise, we deliver faster turnarounds, create permanent component databases, and ensure long-term availability of critical parts.

The result? Lower inventory costs, improved uptime, and major savings across wastewater applications.

Get tailored Support for your Industry by Experts today:

Let’s start the conversation.

At ERIKS, we pair technical expertise and tailored engineering solutions with a full spectrum of high-quality industrial products.

Whether you're looking for specialist bearings and seals, compliant drive systems, condition monitoring, or OnSite maintenance, we serve every major UK industry, including food and drink, healthcare, pharma, defence, oil & gas, renewables, wastewater and more.

Speak with our team today to explore how we can help reduce downtime, improve productivity, and drive cost efficiency.

Fill in the form and one of our industry‑experienced specialists will:

- Provide a custom product quote or technical advice

- Arrange site visits or design support

- Help with digital trading, supply chain integration or MRO solutions

- Proven across critical sectors, from pharmaceuticals to infrastructure and transport

- Engineering services to save time and reduce overall lifecycle cost

- Nationwide support via regional hubs with onsite workshops, machining and customisation cells

Your challenges are unique and our solutions are adaptable.

Submit your enquiry and we’ll connect you with the right expert within the UK and Ireland network.

How to Contact ERIKS

Get in Touch

Looking for a custom Product quote? Need an answer to a Technical question? Looking for Careers/HR support? Want to work with us? Interested in our Digital Trading solutions? Have a finance question? Send us your enquiry and a member of the ERIKS team will be with you quickly.

How are we doing?

We strive to deliver exceptional quality service and products. As part of this goal, we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us or find your local Branch

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.

Call us: +441215086000