In this article

Turning up the heat on electrical efficiency

Uncovering electrical faults before they reach failure

Industry Sector:

Food and Beverage

Application:

Electrical distribution and switch rooms

Risk removed:

14+ high-severity electrical faults

Payback period:

Immediate

Product/Service:

- Fault diagnosis and reporting

- Predictive mainteance audit

- Electrical thermographic survey

Customer Benefits:

- Early fault detection

- Increased plant safety

- Improved equipment reliability

- Reduced unplanned downtime

A large-scale food processing facility was facing regular maintenance challenges with its electrical distribution systems. With a growing number of assets, ranging from control panels and switchboards to effluent plant systems and refrigeration switch rooms, visibility of potential faults was limited.

Challenge

Internal teams suspected some equipment was operating under excessive load, but without the means to confirm this, there was growing concern that critical failures could occur without warning — potentially affecting production uptime and site safety.

The customer approached ERIKS to carry out a thermographic survey across multiple locations within the facility. The goal was to assess electrical integrity, identify signs of overheating or load imbalance, and help reduce the risk of equipment failure — all without shutting down operations.

Solution

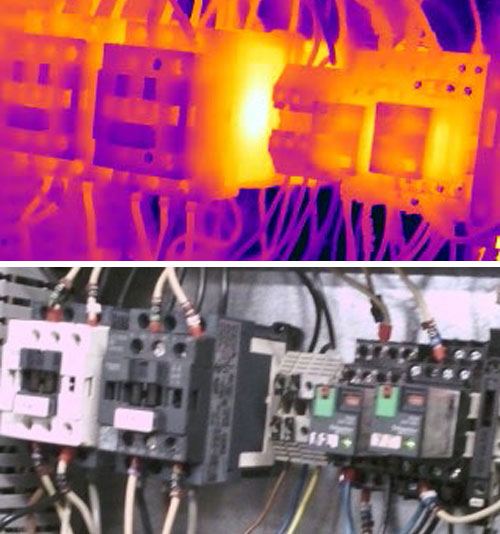

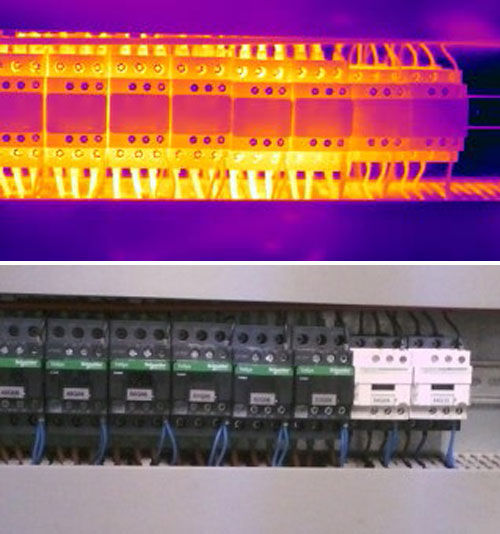

Over a three-day period, an ERIKS Thermography Engineer carried out a detailed thermal inspection using a FLIR E75 infrared camera. The survey was conducted live, with systems under load, ensuring that heat patterns reflected actual operating conditions. Panels across key areas — including the VHI switch room, boiler house, primals switch room, and engineering workshop — were assessed and imaged.

The high-resolution thermal data revealed multiple areas of concern. Several panels displayed signs of possible overloading, with component temperatures exceeding 70°C in certain instances. In total, over 14 anomalies were documented, each with detailed temperature measurements, severity ratings, and corrective recommendations. All images and results were compiled into a clear, structured report — allowing the customer to see precisely where action was needed.

Each fault was categorised by severity using ERIKS’ industry-aligned fault rating method, helping the maintenance team prioritise repairs. Issues ranged from localised hot spots and phase imbalances to ageing transformers and resistors nearing the end of their operational life.

Result

The thermographic survey gave the customer immediate visibility of hidden electrical faults, many of which would not have been detected during routine inspections. Armed with ERIKS’ insight, the engineering team was able to take fast, targeted action — checking loading conditions, replacing overstressed components, and proactively addressing wiring issues before they could escalate.

The result was a significantly safer and more resilient electrical infrastructure. By resolving thermal faults early, the customer avoided potential downtime, reduced the risk of electrical fire, and improved the long-term reliability of key assets, all without disruption to their operations.

The thermographic survey did more than just identify faults, it delivered real value by improving safety, efficiency, and confidence across a complex, high-demand site. With ERIKS' support, the customer has strengthened their maintenance programme and laid the groundwork for longer-term reliability improvements across their electrical infrastructure.