In this article

Trapped losses. Released savings.

Thermography exposes failures and improves efficiency

Industry Sector:

Food and Beverage

Application:

Steam system - process and building services

Failures identified:

6 defective traps requiring action

Payback period:

Immediate

Product/Service:

- Predictive maintenance support

- Fault analysis and severity report

- Steam trap thermographic survey

Customer Benefits:

- Reduced energy waste

- Improved system efficiency

- Informed maintenance planning

- Prevented equipment degradation

Steam traps play a vital role in food manufacturing, ensuring that steam systems operate efficiently by discharging condensate without losing live steam. However, when traps fail — whether stuck open or closed — the resulting impact can lead to increased energy consumption, reduced heating performance, and long-term damage to system components.

Challenge

At a major food processing facility, the customer requested ERIKS to carry out a full site survey of steam traps following internal concerns over irregular temperatures and suspected inefficiencies. The site spans multiple areas, including roof space processing, the boiler house, and ancillary production areas — all reliant on steam for heating and critical process functions.

The customer needed clarity, not only on where traps were underperforming, but also which ones required immediate attention versus those to simply monitor. With energy costs rising and sustainability targets looming, the business was keen to act fast.

Solution

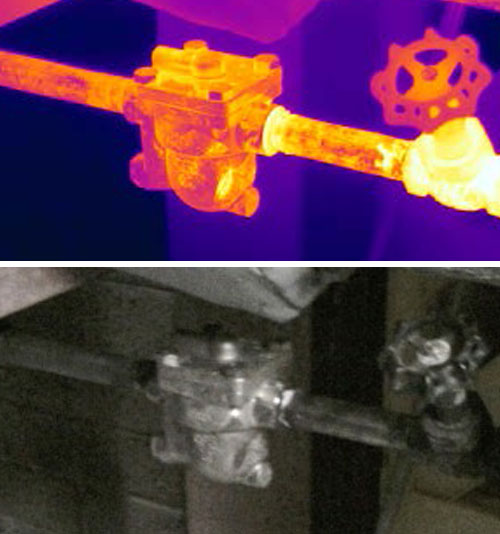

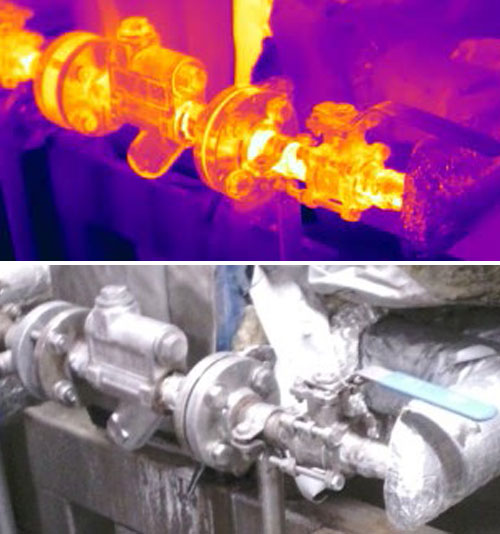

ERIKS deployed a certified Thermography Engineer to the site over three days, conducting a detailed thermal imaging survey using the FLIR E75 camera. Each steam trap was evaluated in-situ, with temperature readings taken at inlet and outlet points, supported by high-resolution thermal imagery. The assessment also used a defined severity matrix to classify each trap’s operational status and recommend the next steps.

A total of 20 traps were inspected across the facility, from boiler house calorifiers and hot water skids to steam-fed cookers, smokers and tunnel systems.

Of these, six traps were identified as faulty, most commonly due to being stuck open or not closing properly. In these cases, temperature differentials were minimal — indicating poor condensate removal and energy loss due to live steam passing through.

Several other traps were marked for ongoing monitoring. These included traps showing low activity — either due to being in standby mode or simply operating intermittently due to current load conditions. All results were clearly documented and matched with the corresponding plant location, component ID and recommended action.

Result

ERIKS delivered a clear, visual summary of steam trap performance across the site - identifying failures, borderline units and functioning traps with supporting thermal data. This gave the customer a prioritised plan for corrective action, enabling them to focus maintenance efforts where they would have the most significant impact.

For the traps that were failing, or stuck open, immediate replacement or repair was advised. By addressing just those six identified failures, the customer stands to significantly reduce energy waste and protect downstream systems from potential wear or performance degradation. Traps marked for observation will be rechecked in the next scheduled survey.

With steam playing such a critical role in production, the insight provided by ERIKS has helped the customer regain control over a key part of their infrastructure.

The survey also reinforced the customer’s commitment to energy efficiency and best practice maintenance, providing auditable evidence for internal ESG reporting.