In this article

Thermal imaging delivers big returns

Cutting-edge condition monitoring delivers the dairy

Industry Sector:

Food and Beverage

Application:

Full Site Inspection

Actual Saving:

£416,000

Payback period:

N/A

Product/Service:

- Condition monitoring

- Thermal imaging assessment

Customer Benefits:

- Energy savings

- Improved efficiency

- Sustainability improvement

One of the UK’s leading food producers, famous for household favourites found in millions of kitchens, runs a major dairy that never sleeps. Operating around the clock, the site relies heavily on steam to keep production flowing – making energy efficiency not just a priority, but essential to success.

At a time when energy prices are soaring and sustainability targets are under increasing scrutiny, even small inefficiencies can snowball into major operational costs. Drawing on our decades of experience and modern thermal imaging technology, we helped this Dairy Manufacturer to identify, quantify, and correct heat loss issues that were quietly costing hundreds of thousands of pounds.

Challenge

Steam is essential to the round-the-clock production process – whether it’s for processing ingredients or sterilising equipment – especially in areas where whey is processed for baby food. But steam is also expensive. If pipework and valves aren’t properly insulated, energy escapes fast, hitting both operational efficiency and the bottom line.

The customer already suspected that energy was being lost, but needed clear, data-backed insights to take meaningful action. Enter ERIKS’ condition monitoring team, who have been using thermal imaging for more than 30 years – not just to identify electrical faults, but to detect hidden heat losses in industrial systems.

Solution

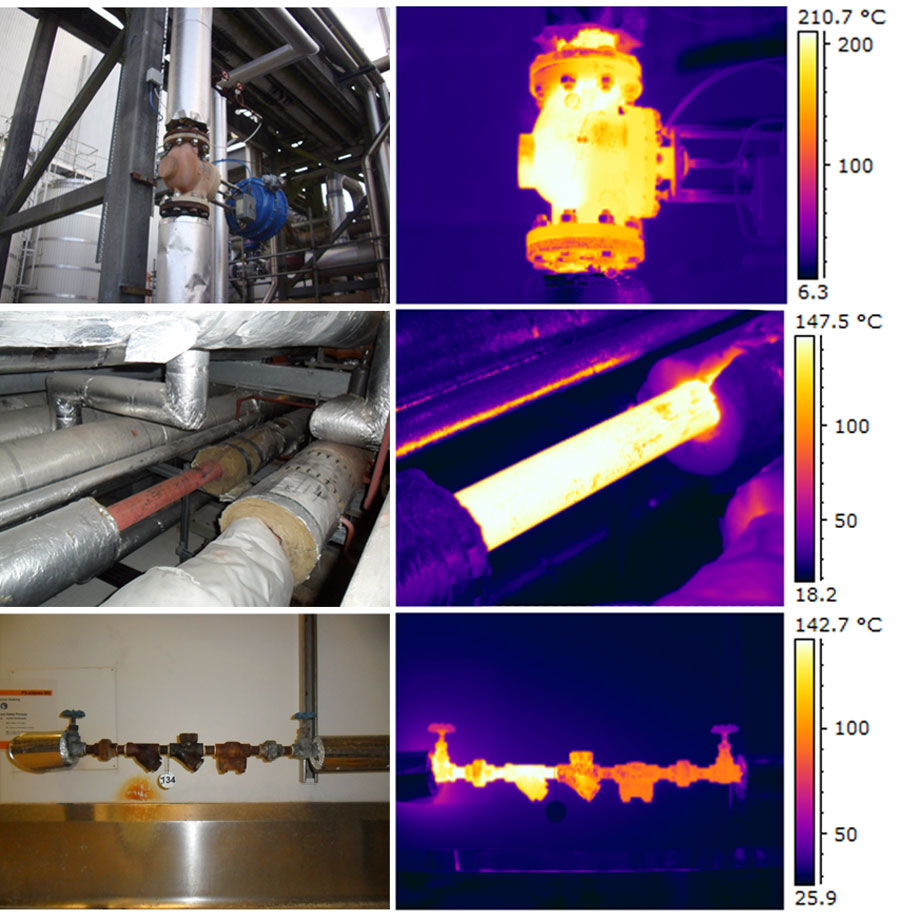

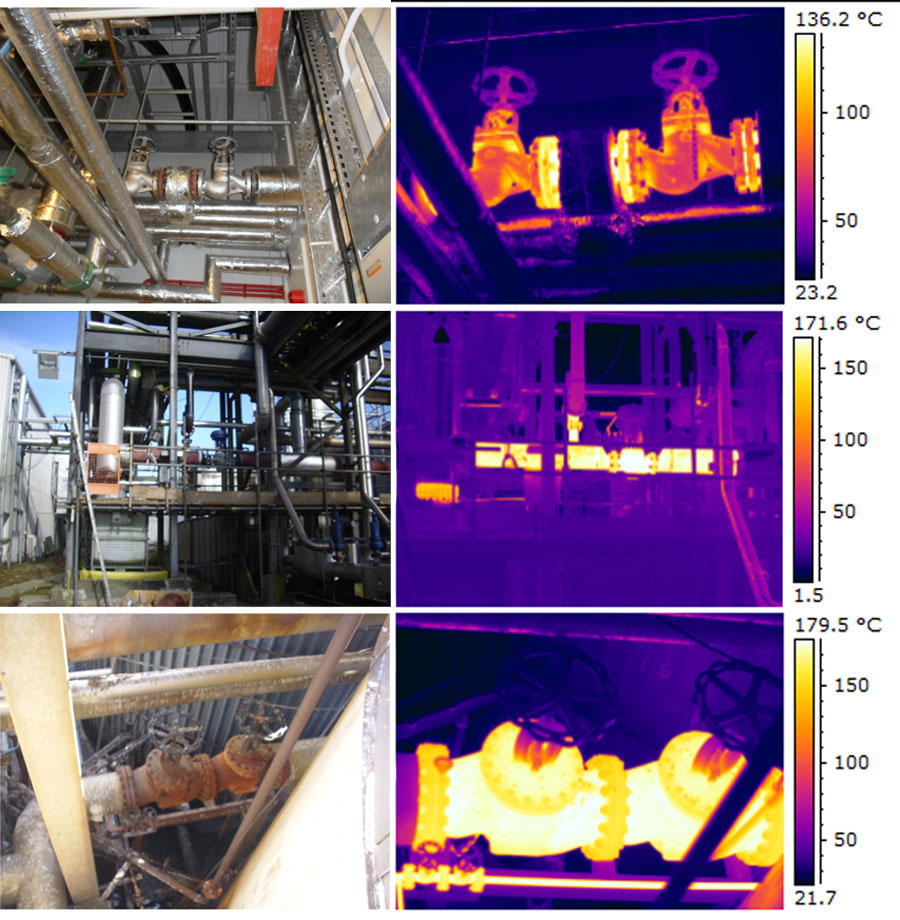

ERIKS conducted a targeted thermal imaging assessment of the site’s steam and hot water infrastructure. The initial sample focused on five or six areas suspected of inefficiency. Using high-resolution thermal imaging cameras, ERIKS technicians quickly pinpointed several hotspots of energy loss.

One clear example was an aluminium shroud atop a steam pipe. The valve beneath had been repaired, but the insulation had not been replaced afterwards – a common issue in busy production sites. Thermal images highlighted significant heat escape from these zones.

Each image in the report was backed by photographs, a description of the issue, and actionable recommendations. ERIKS were also able to quantify the impact in real financial terms: the sample alone revealed over £13,000 in potential annual savings.

The data was enough to convince the customer to greenlight a full-site assessment.

Result

The full assessment uncovered over £400,000 in avoidable energy losses across the dairy. The report was shared with the ERIKS team, who collaborated with local insulation partners to swiftly action the repairs. In some cases, parts were supplied directly by ERIKS, while other fixes were handled internally by their own team

Following repairs, ERIKS carried out a follow-up thermographic survey to ensure all recommended improvements were effective. The verdict? The savings estimate was spot on.

Beyond the impressive financial win, the project also contributed to the customer’s wider environmental goals – by cutting unnecessary energy use and improving the efficiency of their round-the-clock operations.