In this article

Subsea confidence restored with engineering expertise

Solving sealing failures through teamwork and expertise

Industry Sector:

Oil & Gas

Application:

Subsea wellhead sealing

Actual Savings:

Cost avoidance £1m/day,

over £11,000 scrap cost avoided

Payback period:

Immediate

Product/Service:

- PTFE Rings

- Sealing & Polymer

Customer Benefits:

- Full certification

- Independent testing

- 50% reduction in lead time

- Technical support from ERIKS

- Stronger relationship with ERIKS

- Made to drawings and tolerances

A long-standing ERIKS International customer in the oil and gas sector encountered a major technical failure with a mission-critical PTFE ring – a component designed as an anti-extrusion back-up to protect primary O-ring seals used in subsea wellhead assemblies.

Challenge

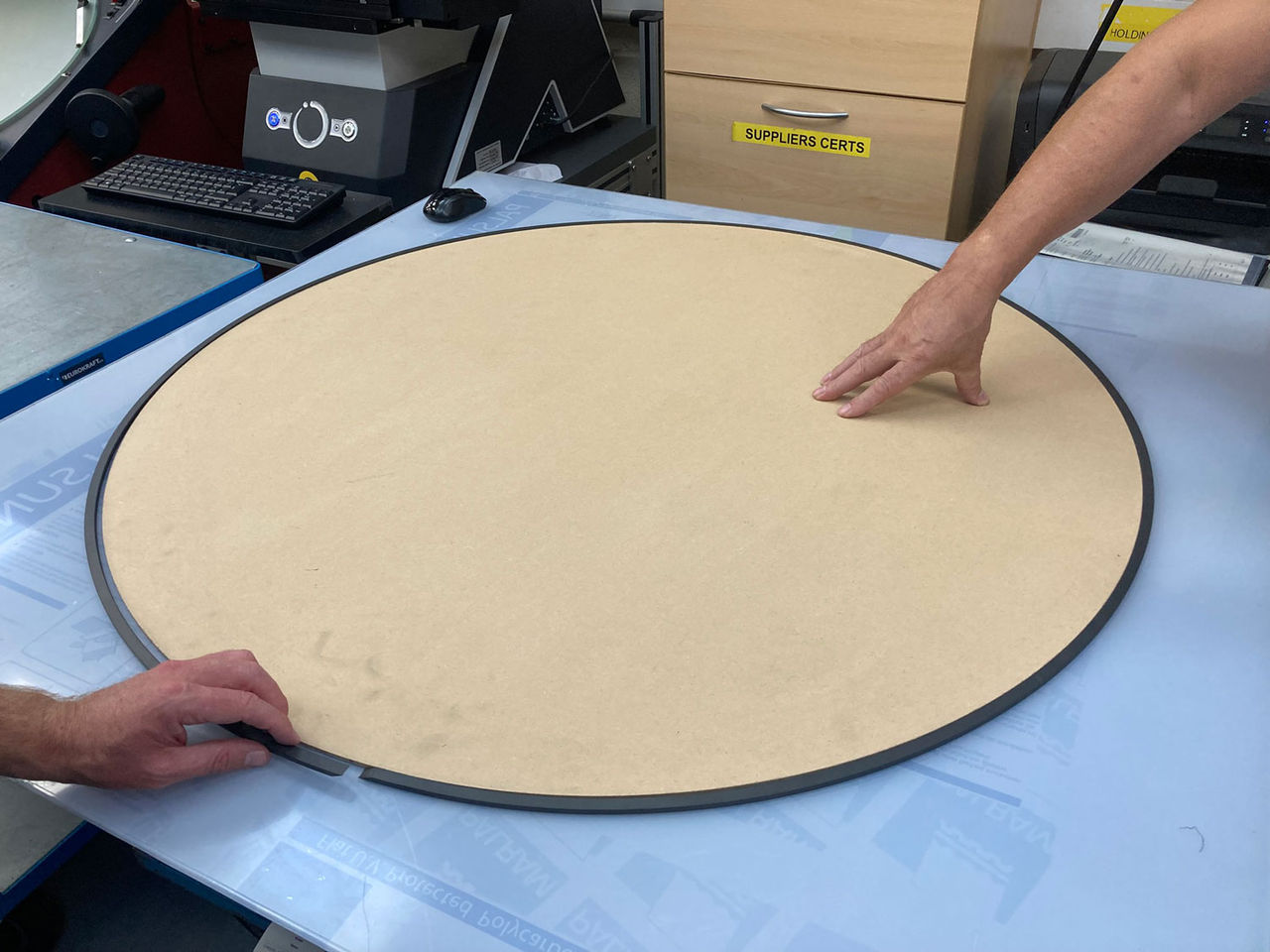

These rings, over 1 metre in diameter, are engineered from PTFE and operate in high-pressure, deep-sea conditions where failure is not an option. Their role is to provide support against pressure differentials that would otherwise cause the primary elastomeric seal to deform or extrude. When the gap between the ring ends exceeds the allowed tolerance, extrusion risk rises exponentially – compromising seal integrity and, ultimately, the functionality of the entire assembly, and stopping production.

For over seven years, these rings were supplied without issue. However, over a 12-month period, the customer began reporting dimensional failures. Rejected components showed out-of-tolerance gaps that rendered them unusable and unfit for critical subsea deployment.

With replacement costs at over £1,400 per ring, and eight units already scrapped, the customer faced a material financial impact. Worse still, delays to offshore installation schedules created significant risk exposure, with operational downtime conservatively estimated at £1 million per day.

Initial investigations revealed a troubling picture. The existing supply chain required ERIKS to procure through a third party tied to the OEM. Communication was inconsistent from the OEM, lead times were increasingly unreliable, up to 12 weeks, and the supplier flatly refused to manufacture to the customer’s revised drawing.

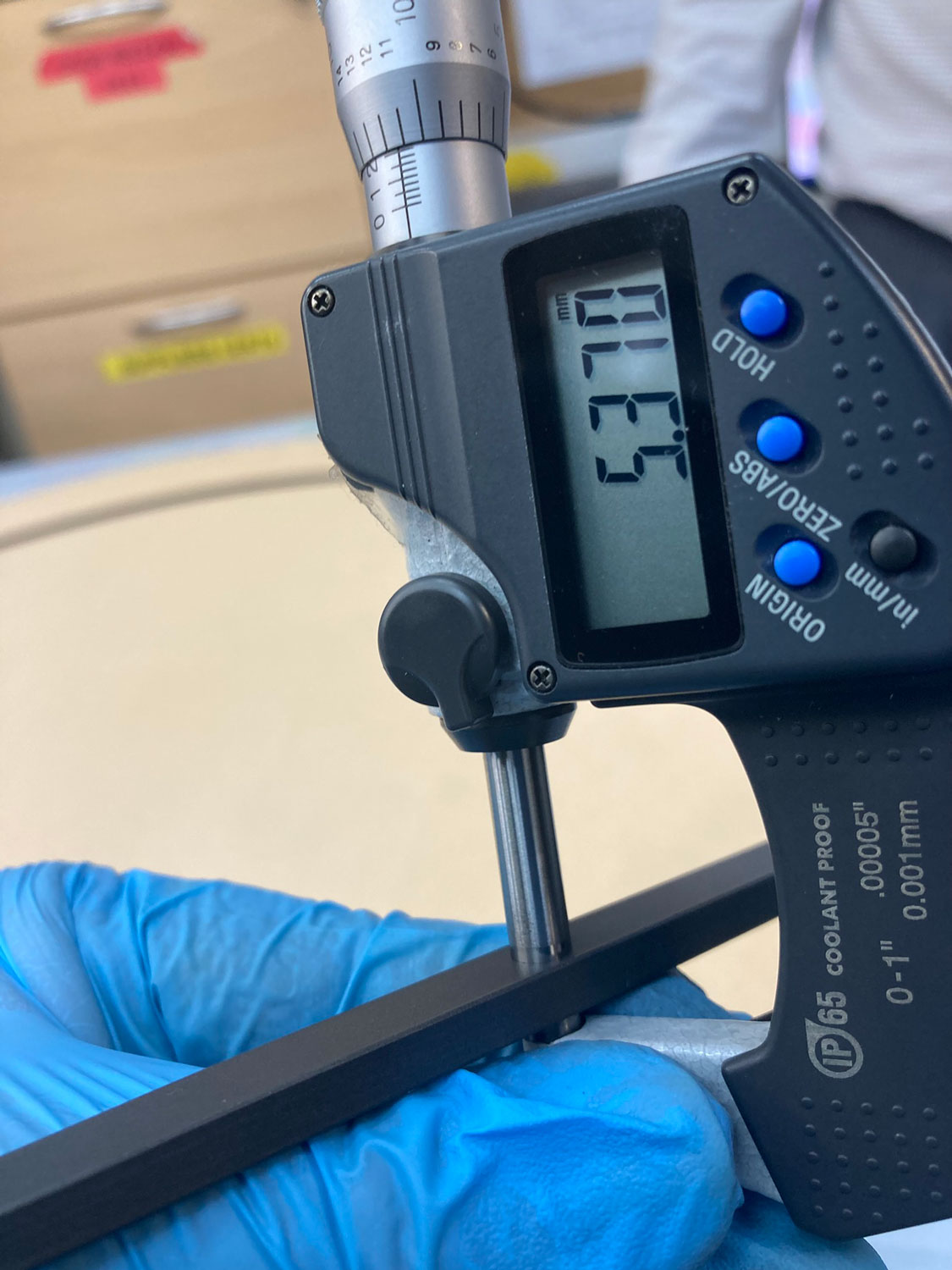

That drawing specified critical dimensional changes – including a new split angle and a defined tolerance on the gap – but the supplier continued to manufacture against their own legacy template, ignoring customer requirements.

As a result, the ERIKS team was left in the middle: unable to influence the supplier, yet responsible for a product that was failing inspection and threatening the customer’s operations. The business risk and reputational damage were mounting, and the customer’s faith in the product was understandably under strain.

Solution

The breakthrough came when the customer issued an update to their technical specification. Crucially, this revision retained the material specification but removed the clause mandating a specific OEM. This subtle shift allowed ERIKS to act decisively and explore alternative supply routes – while maintaining full compliance with customer standards.

Immediately, ERIKS International and ERIKS Sealing & Polymer assembled a collaborative team to tackle the issue. The updated drawing was reviewed in detail, confirming a very tight tolerance band for the ring end gap, revised geometry of the split, and the ongoing requirement for full certification of the material and finished dimensions.

ERIKS then engaged a trusted UK manufacturing partner with proven capability in machining large-format PTFE components. This supplier was able to commit to manufacturing strictly to the customer’s drawing – a key difference from the original source.

Not only did they agree to meet the required tolerances, but they were also willing to work to a significantly shorter lead time of just five weeks, improving responsiveness and agility in the customer’s supply chain.

To address one of the major pain points – inconsistency in gap measurement – ERIKS engineered a bespoke inspection method. A series of five precision discs were manufactured at ERIKS Barnsley gasket facility, all produced to the exact same reference diameter and finish. These discs allowed each party – the manufacturer, ERIKS’ inspection team, and the customer’s representatives – to measure the ring gap under consistent conditions using the same reference point.

This approach also accounted for thermal expansion and ambient temperature during measurement, critical for PTFE components of this scale. With discs distributed globally (including to China, where installation would take place), all stakeholders could conduct accurate, consistent inspections regardless of location.

Result

The first five PTFE rings were manufactured, inspected in-process, and then subjected to dual QA inspection. An independent third-party inspector, commissioned by the customer, verified dimensions and tolerances at the supplier’s site. A second inspection was completed at ERIKS’ own Sealing & Polymer Quality Control Centre in Warrington, where full dimensional reports and material certification were prepared.

To reassure the customer and build trust, ERIKS offered the first batch free of charge – a bold step, with the understanding that payment would only be required if the parts passed inspection. They passed with flying colours – with no dimensional non-conformances and full certification provided.

The rings were shipped to China for installation on schedule, with zero issues reported post-delivery. Since then, further orders have been placed, and the new supplier has proven highly consistent across larger production volumes.