In this article

Hygienic High Performance Bearings for Reliabilty

Reducing food safety risks and extending life

Industry Sector:

Food & Beverage

Application:

Conveyor

Actual Saving:

£206,500

Payback period:

3 months

Product/Service:

- Food grade bearings

- Technical manufacturer support

Customer Benefits:

- Increased mean time between failures (MTBF)

- Eliminated regular lubrication intervals

- Increased food safety

One of the biggest ironies of operating in a clean environment is that the repeated washdowns undertaken to keep equipment clean are one of the main reasons for machinery complications and unreliability.

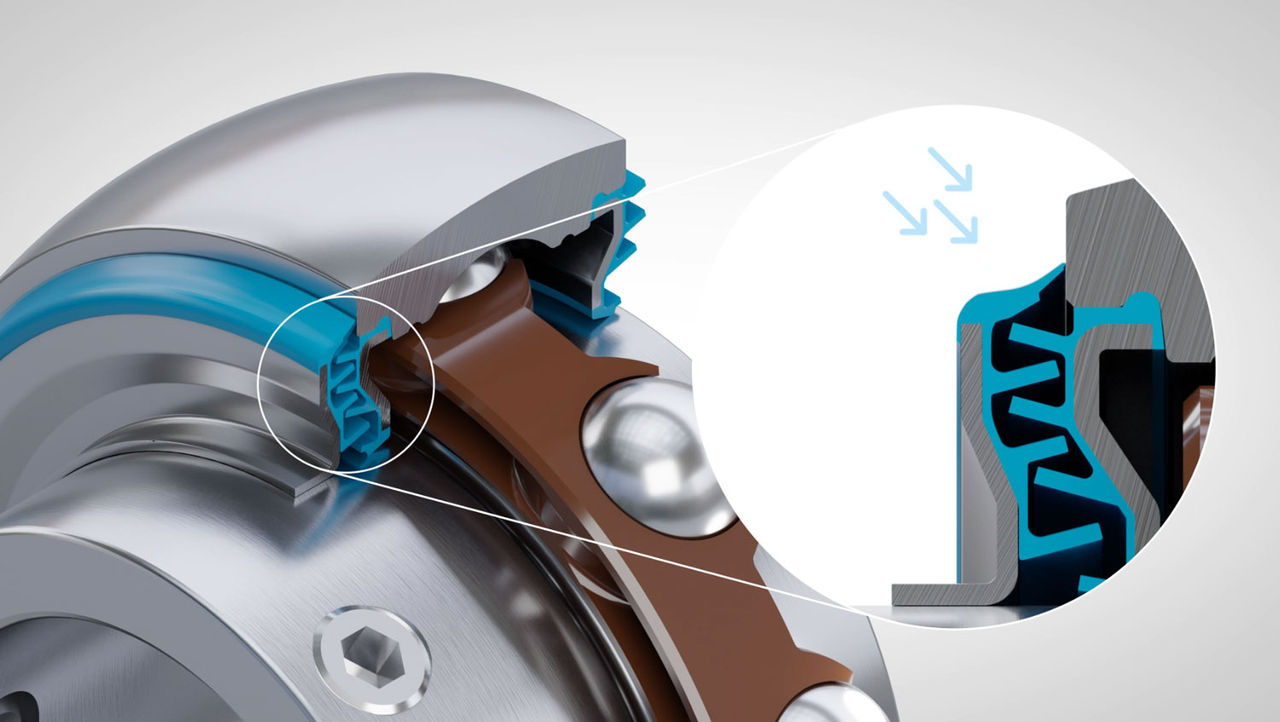

Frequent high-pressure cleaning processes, more often than not, using penetrative anti-bacterial detergents and cleansing agents, over time these detergents become present under seal lips, dissolving sealing efficiency and effecting performance and reliability.

Challenge

A major vegetable processor in the UK was experiencing significant reliability issues with conveyor bearings and suffering subsequent maintenance cost issues.

The operational problems had been ongoing for a number of years, and typically the customer was only achieving a maximum 3 to 6 months service life of their current bearing units, despite good maintenance practices and regular regreasing.

The harsh nature of the wet and humid environment coupled with caustic cleaning and high pressure rinsing made operating conditions extremely difficult, and other bearing solutions had failed to offer any significant return on investment.

Patented bearing sealing system and high performance grease engineered to increase reliability and service life

Solution

SKF and ERIKS worked with the customer to specify the correct solution; SKF Food Line Ball Bearing Units.

The ERIKS and SKF solution was selected due the unrivalled sealing capability, the extended operational life due to the specially selected anti-allergen, high performance grease, and the relubrication free aspects of the SKF Food Line range.

In addition, the innovative hygienic design of the SKF Food Line units offered increased protection against bacterial growth, increasing food safety.

SKF Food Line ball bearing units

The blue colour of the components increase optical detectability, so you could say the benefits were clear to see!

Result

Once installed the customer was able to extend the mean time between failure by a minimum of 300%, whilst also removing the need to relubricate the bearings, removing costly lubricant and manpower hours.

The solution was replicated across several similar applications across the group increasing the annualised savings realised to £206,500.