In this article

No More Leaks: The Gearbox Solution Protecting Product and Processes

Industry Sector:

Food & Beverage

Application:

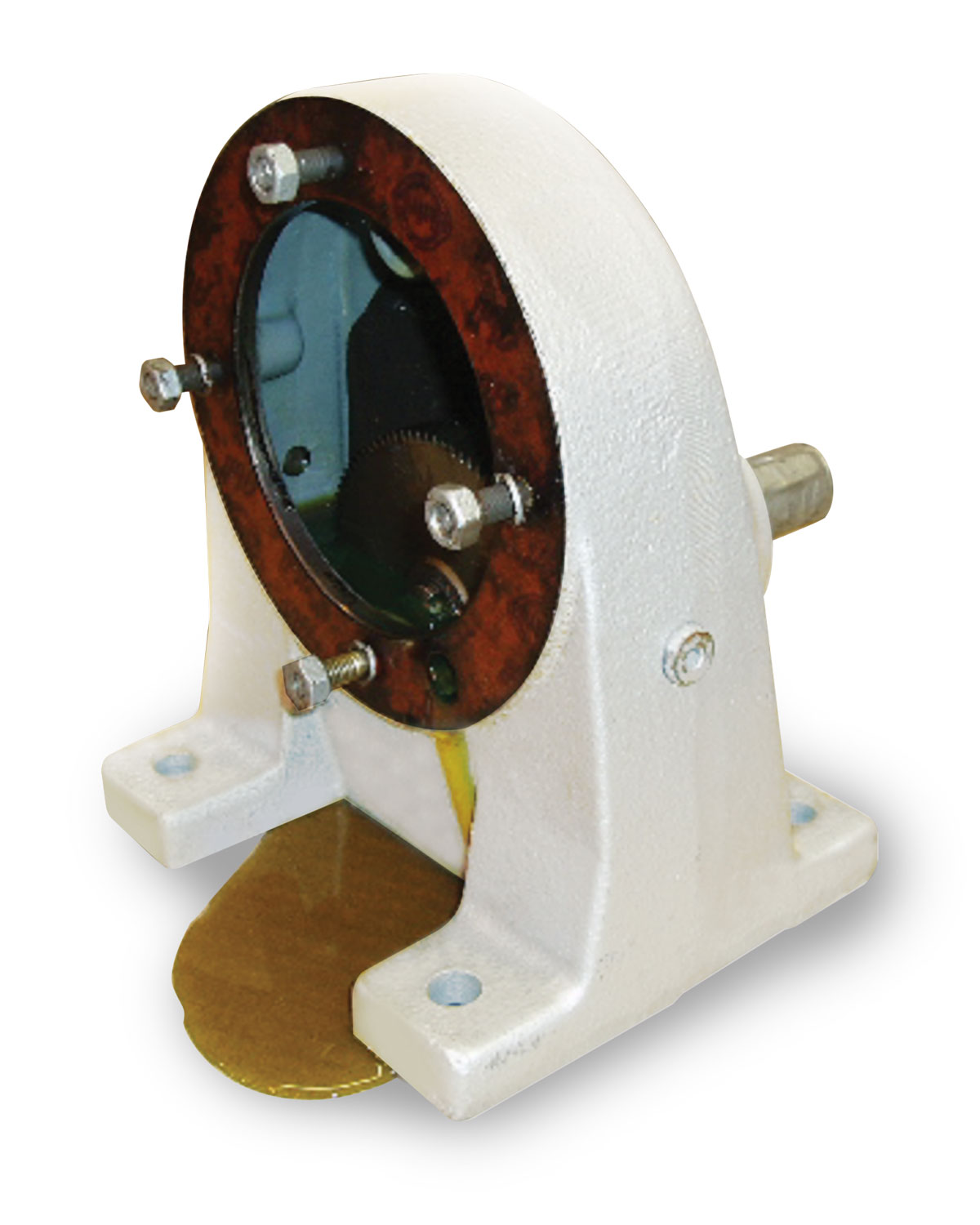

Fenner Dry-Fit Gearboxes

Problem

How long would it take your business to bounce back from a product recall? For one global cereal producer, it was a risk they couldn’t afford to take. A single incident of contamination could have meant a massive product recall, brand damage, lost sales, or worse – an unlimited fine or even a prison sentence under health and safety legislation.

Their biggest concern? Oil leaks from direct-mounted geared motors.

Gearbox sealing was proving unreliable. Over time, oil was seeping into motor windings – causing premature failures – and leaking onto production floors, creating serious safety hazards. Replacing these motors in situ was a time-consuming, messy job, increasing downtime and costs.

Worse still, if any of that oil made its way near the food stream, the consequences could’ve been catastrophic.

As part of a continuous improvement programme aimed at improving hygiene standards and reducing risks, the manufacturer turned to ERIKS.

Solution

ERIKS Application Engineers recommended a smarter alternative: standardising to a Fenner geared motor range, with a key feature – a dry-fit adaptor housing two seals between gearbox and motor.

This upgrade delivered game-changing benefits:

- Cleaner and safer: Double-sealed design dramatically reduced the chance of oil escaping, either onto floors or into sensitive production areas—supporting the customer’s drive for higher hygiene standards.

- Minimal downtime: In the rare event of a motor failure, it could now be replaced easily and cleanly—just four screws and no need to dismantle the gearbox or risk spills, which significantly improved maintenance efficiency.

- Extended equipment life: With oil kept where it belonged, both gearboxes and motors operated more reliably and lasted longer, reducing the frequency and cost of unplanned repairs.

- Streamlined spares: Thanks to the IEC-standard frame, the customer reduced stockholding and had more flexibility in sourcing motors, making procurement quicker, simpler and more cost-effective.

For just a few hundred pounds, this cereal manufacturer avoided costly contamination risks, improved site cleanliness, enhanced worker safety, and slashed downtime.

A small change, with a big impact - exactly the kind of result their Continuous Improvement programme was designed to deliver.

Sign-up for Support for your Industry:

A Team member will review your enquiry and respond promptly.