In this article

Leading name in cereal eliminates the ‘flush’

Product improvement offers immediate impact

Industry Sector:

Food & Beverage

Application:

Coating Line Spray Pumps

Actual Saving:

£3,000

Payback period:

Immediate

Product/Service:

- Re-engineering

- Problem Solving

- Flow Control Pumps

Customer Benefits:

- Risk mitigation

- Energy Savings

- Maintenance Reduction

- Environmental Compliance

- Reduced Water Consumption

You are standing in the middle of a cave, and your trusty torch cuts out, or even that dreaded loss of internet connection during your crucial virtual meeting!

The fact of the matter is that there is never a good time for equipment failure, which is particularly true when you are a leading cereal manufacturer, and breakfast is the most important meal of the day!

Challenge

A global breakfast cereal manufacturer relied heavily on water to flush their lobe pumps which transfer and transport product through several parts of their production process. These pumps were more than capable of completing the desired task. However, frequent mechanical failures had become all too familiar within the application.

These failures occurred from differing sources in the system, mainly resulting in operating errors leading to over pressure and lack of operation on the seal water flush, which in turn was causing premature failure of the seals themselves.

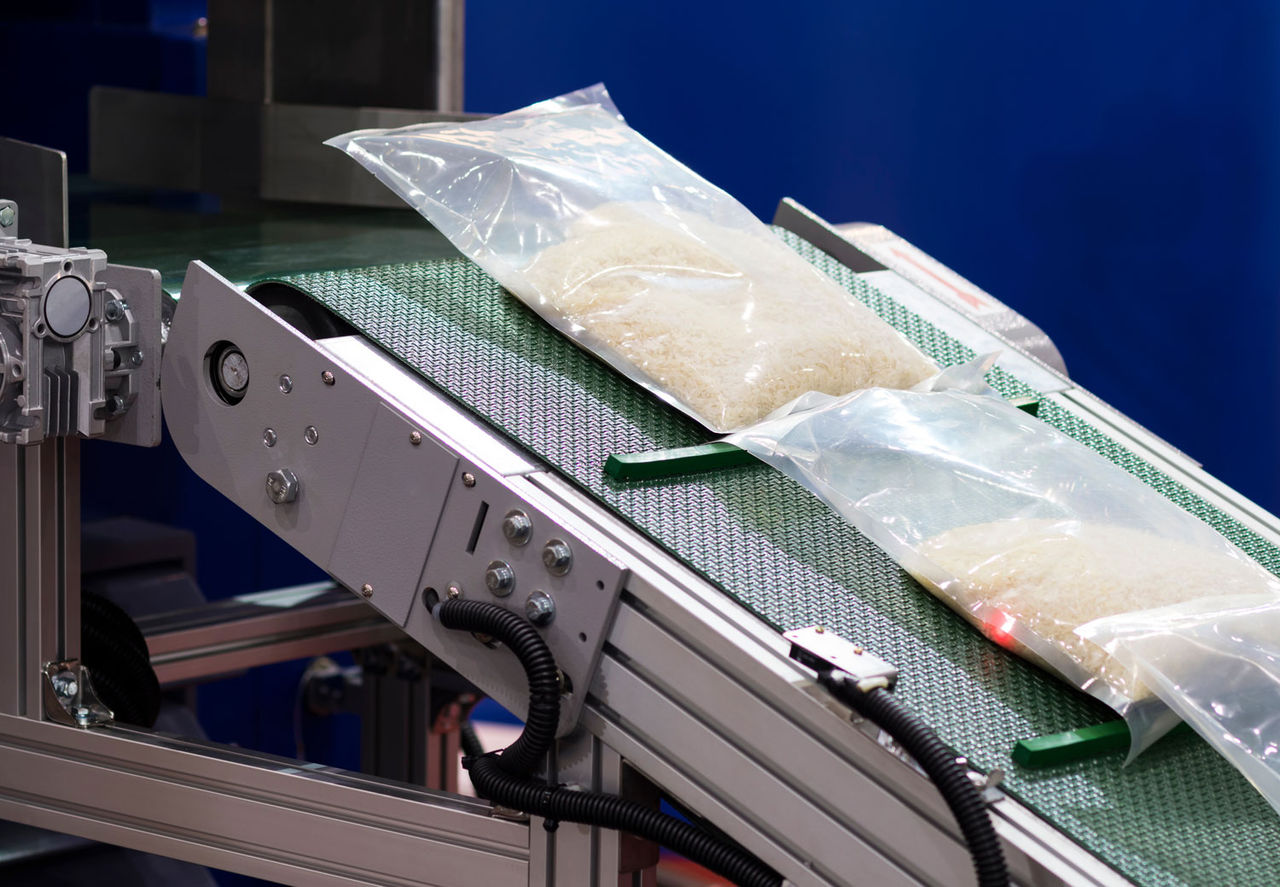

Cereal production

Solution

With an ever-growing focus on sustainability, the simple things can make a big difference. Given that the current application was offering a high volume of water waste, a solution was required to provide a more reliable and greener solution.

After completing the relevant inspection, the ERIKS pump application engineer identified that the existing water flush pump was in dire need of replacement and suggested an upgrade to a Mouvex sealless pump. Offering improvements in performance and reliability and, perhaps more importantly, eliminating the need for the original water flush required by the existing pump.

Moveux Sealless pump

Result

Since replacing the incumbent pump, the customer has benefitted from significant reductions in water waste. In addition, process efficiency and reliability have improved, food safety compliance has been adhered to, and reduced running costs have been realised. With an initial saving of £3,000 on this pump alone, the additional savings that can be achieved across the site are significant, making for a more reliable and sustainable future.