In this article

Keeping Hospital Air Handling Units Safe and Compliant

Industry Sector:

Infrastructure

Application:

Air Handling Units

Problem

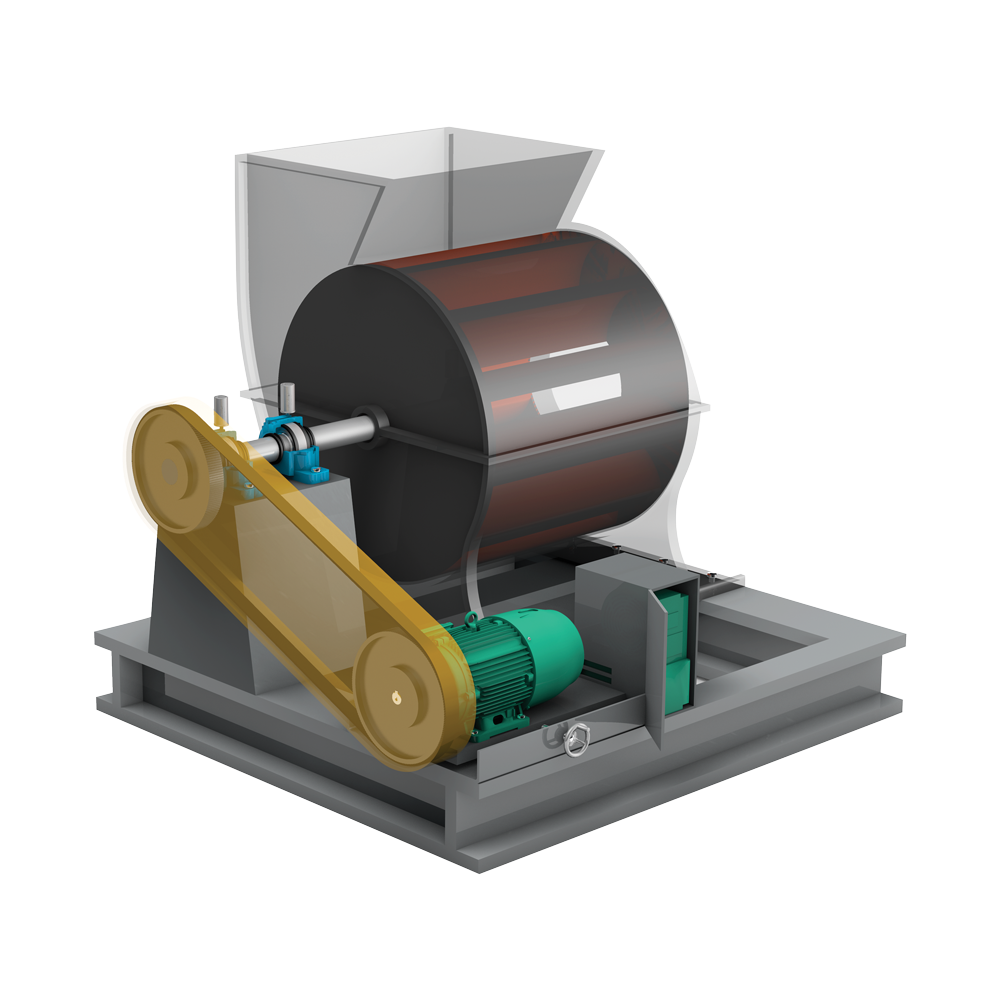

When an AHU fails to deliver enough airflow, theatres risk non-compliance, which directly impacts patient safety and surgical outcomes. Common issues, such as worn belts, inefficient pulleys, misaligned drives, fans which are no longer in balance, and ageing motors, often leave facilities struggling to meet these essential ventilation requirements.

Beyond compliance concerns, these inefficiencies can increase energy bills, raise maintenance costs, and shorten equipment lifespan.

ERIKS have experience in overhauling existing AHU’s to increase airflow, improve reliability, helping ensure the theatre is available and compliant within tight NHS budgets and schedules.

One NHS hospital recently faced a significant challenge: their operating theatres were being used more frequently, increasing the demand on their AHUs. This extended usage strained the existing systems.

To ensure conditions didn’t fall below the required 25 ACH, putting both patient safety and the hospital’s operational efficiency at risk, the hospital turned to ERIKS for a practical, cost-effective solution.

Solution

First, the ERIKS team conducted a thorough on-site assessment, pinpointing exactly which components were holding back airflow performance. With a clear picture of the situation, we set about upgrading key parts of their existing AHUs.

ERIKS assessed the pulley sizes and upgraded belts to a higher-spec Fenner belt. Crucially, we also replaced the existing pulleys, which are often overlooked when belts are swapped out, yet essential since worn pulleys can significantly impair drive efficiency. Alongside new Taper Lock bushes for quick, secure installations, these upgrades immediately enhanced the drives’ existing capacity, boosting fan speeds and airflow rates.

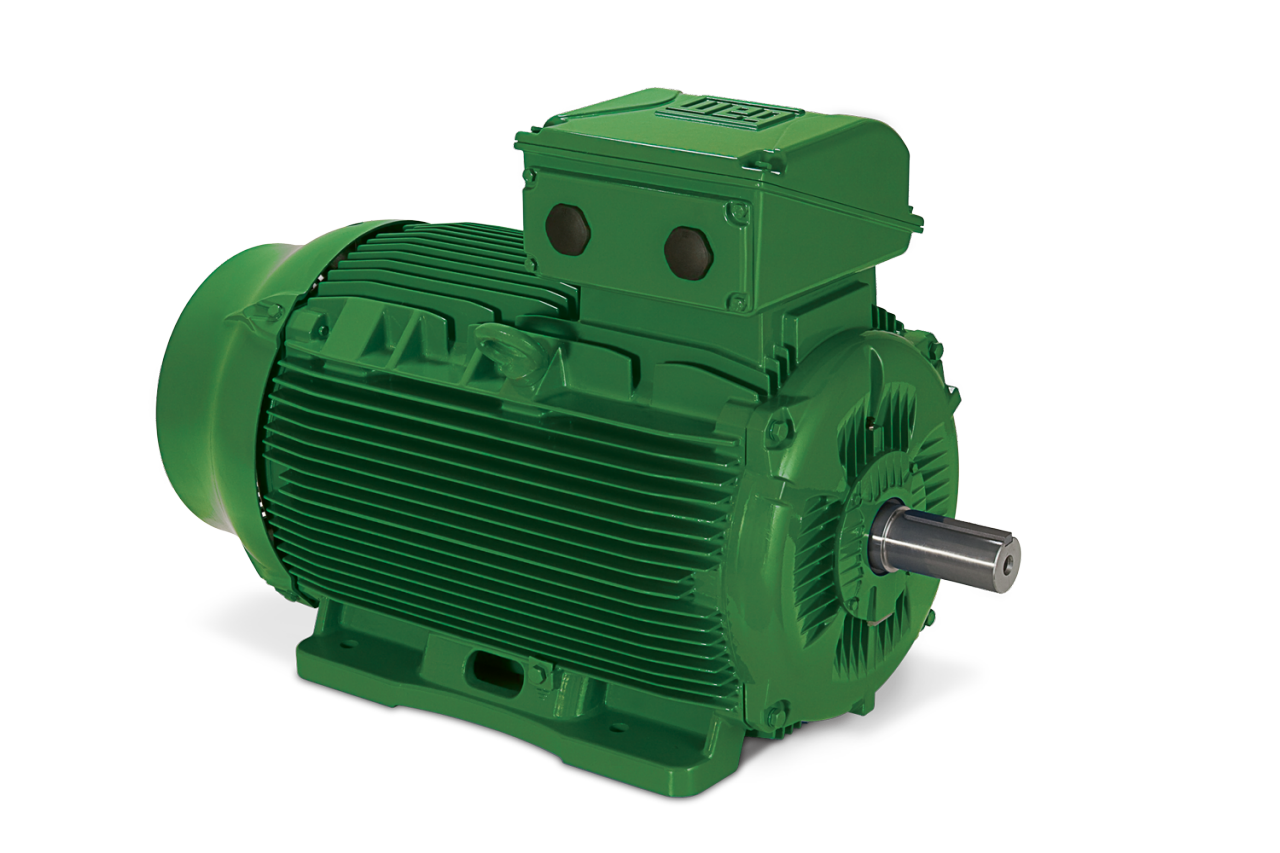

With the component parts of the drive assessed, ERIKS looked at the existing motor, the decision was made to upgrade to a more energy-efficient model. In this case, due to the increased use of the theatre, a new IE4 motor would be more cost effective verses an overhaul of the existing asset — ERIKS offer a comprehensive motor overhaul and repair service to restore and maximise a motors lifespan whenever economically viable.

Our specialists then precisely balanced the fan, eliminating vibrations, reducing noise, and further enhancing reliability. ERIKS’ field services team handled the entire project from start to finish—including careful removal of old components, precise installation of new assemblies, and professional laser alignment to ensure perfect integration and optimal performance.

The outcome? Improvements in airflow, reduced downtime, lower energy bills, improved reliability, and peace of mind.

By partnering with ERIKS, the hospital didn’t just solve their airflow challenges—they improved efficiency, compliance, and future-proofed their AHUs.

Sign-up for Support for your Industry:

A Hospital Team member will review your enquiry and respond promptly.