In this article

Bridging the Gap: Upgrading Outdated Infrastructure One Tank at a Time

Industry Sector:

Water and Wastewater

Application:

Settlement tank drive systems

Problem

At a wastewater treatment plant in Scotland, ageing infrastructure was beginning to show its limits. The site features a series of round settlement and storm tanks that rely on motorised bridges to keep water in motion and prevent solids from settling on the bottom.

However, many of the bridge drive systems were outdated, worn, and difficult to maintain. Across the sit, 20-30 drive units were in various stages of disrepair. Frequent failures – especially in motors and bearings – were disrupting operations and threatening the site’s ability to maintain optimal performance.

Several factors were contributing to the failures:

- Outdated designs using open bevel gears and unsupported shafts

- Increased loads from added equipment like aeration systems

- Limited access due to handrails and tank positioning

- High maintenance demands with minimal standardisation of parts

- Severe weather exposure, which caused snow buildup and further complications

The consequences were significant – ranging from costly downtime and manual interventions to long-term damage of tank infrastructure due to excessive wear and misaligned assemblies.

Solution

ERIKS was called in to reassess the entire drive system on the final settlement tanks. Working closely with the customer and site engineers, ERIKS helped co-design a robust, low-maintenance solution that addressed both performance and safety challenges.

The Fenner Cyclo foot-mounted gearmotor was chosen for its high torque, compact footprint, and maintenance-free operation. The chain drive was retained for its torque transmission efficiency but repositioned inboard to avoid interference with railings and improve service access.

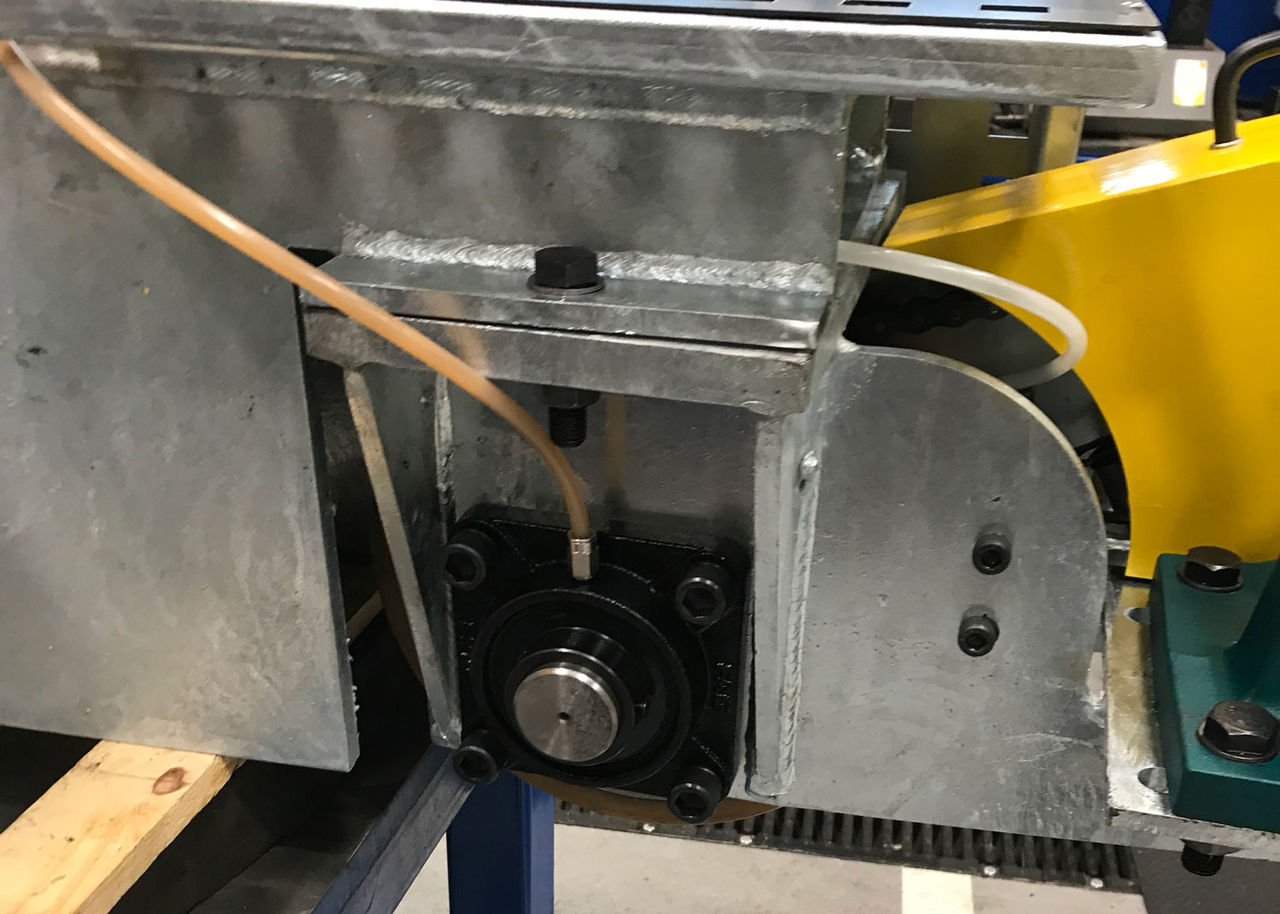

For bearing performance, ERIKS specified Timken® spherical roller bearing solid-block housed units - engineered for high-load, high-contamination environments. Unlike conventional bearing housings, these solid-block units feature cast-steel housings and high-performance Timken bearings, offering unmatched strength and durability. With the ability to tolerate shaft misalignment up to ± 0.75 degrees without reducing bearing life, they were ideally suited to the site’s structural challenges.

Further upgrades included, a fully guarded drive systems to meet current health and safety standards, The addition of an automatic lubrication system to maintain chain and bearing health with minimal intervention, along with a custom ‘snow plough’ attachment with a wiper blade to prevent snow build-up and bridge stalling during severe weather.

The new system not only solved the mechanical issues, but also dramatically simplified maintenance. ERIKS then rolled out the same upgrades across the site’s primary and secondary tanks, incorporating the same Cyclo drives, bearings, wheels, and shafts - creating a universal setup with interchangeable spares.

On the primary tanks, further design refinements allowed for a built-in jacking system, enabling service without the need for expensive lifting equipment.

Over two years, ERIKS helped transform the site from a fragmented and reactive maintenance model to a standardised, reliable, and future-proofed drive system. Improving site uptime, simplifying servicing with fewer unique parts, enhancing safety and compliance, and significantly reducing maintenance demands

Thanks to the co-engineered approach and Fenner’s proven drivetrain technology, the customer now has a robust system ready to meet current and future needs - with ERIKS as a dependable long-term partner.