In this article

£180,000 saved from the skip

How ERIKS brought gearboxes back from the dead

Industry Sector:

Construction

Application:

Mill drive

Actual Saving:

£182,228

Payback period:

N/A

Product/Service:

- Gearbox

- Repair

Customer Benefits:

- Less wastage

- Reduced costs

- Greater sustainability

- Reduced delivery time

Of all the things you might find in a skip, a serviceable gearbox shouldn’t be one of them. But when the original manufacturer assessed a gearbox as failed beyond repair, that’s where it ended up. Fortunately ERIKS were on hand to rescue and repair it. And rebuilding that gearbox built ERIKS reputation for resurrecting similarly failed assets.

1st gear – off to a good start.

Next time the customer was having issues with a gearbox – this time a roll secondary gearbox – approaching the original equipment manufacturer wasn’t an option. They were no longer in business. There was also no spare in the stores.

An alternative manufacturer quoted a 22-week delivery time for a replacement gearbox, at a cost of £99,103.45.

Throwing a gearbox away is one thing. Throwing money away and waiting over 5 months before there’s anything to show for it is another. Remembering ERIKS’ previous successful gearbox resurrection, the customer got in touch.

Challenge

The customer believed issues with their underperforming roll secondary gearbox were due to a misaligned casing. Unable to return to the original manufacturer, they approached ERIKS for advice. Was there an alternative to buying a costly replacement gearbox on a long delivery timescale?

After a site inspection visit from ERIKS, a strip and inspect quote was approved by the customer, and the gearbox was removed to the ERIKS Core Competence Centre – Gearbox Repairs, at Pensnett Industrial Park in the West Midlands.

The inspection showed that the gearbox casing was aligned correctly, but that there were issues internally with the gears themselves.

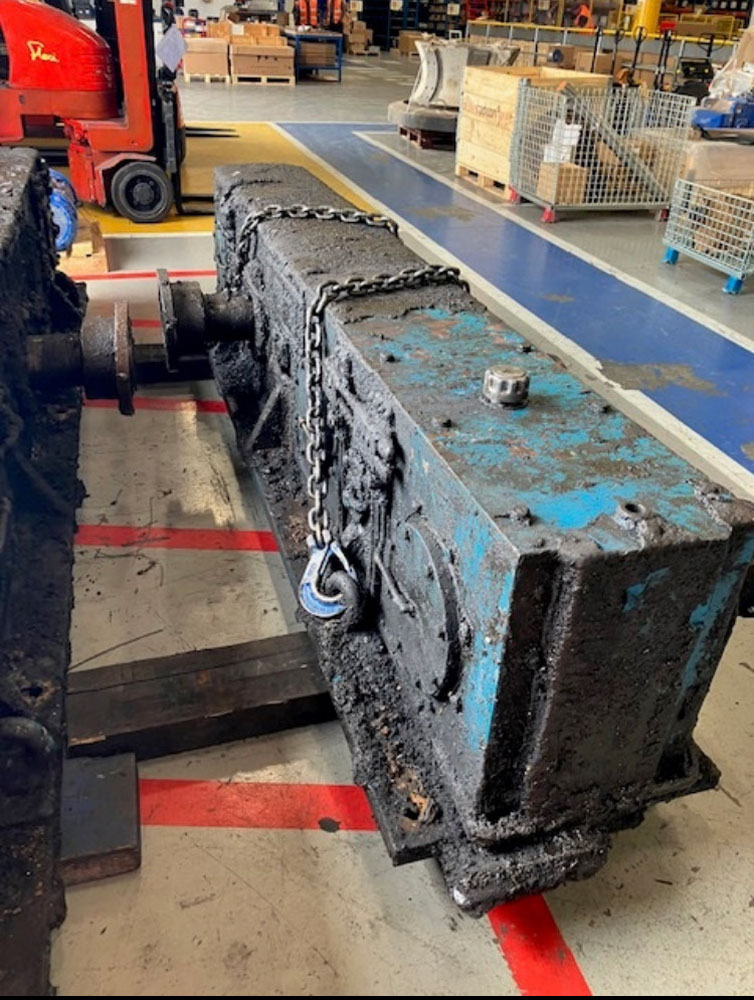

Customer's gearbox unloaded at the ERIKS Workshop (Pensnett)

Solution

The customer’s Spares Planner and two of their Mechanical Engineers visited the specialist ERIKS Gearbox Repairs workshop to discuss possible options.

ERIKS proposed a Non-Warranty repair to restore the asset to a workable condition, and to extend its service life by several years. This solution would involve remanufacturing the gears, and rotating them so they would mesh with the unworn area of the edge.

Customer's Spares Planner and 2x Mechanical Engineers visting ERIKS Workshop (Pensnett)

Result

The cost of the repair was quoted at £28,155, plus shipping and insurance costs of £700. Compared with the competitive quote for a new gearbox, this represented an overall saving of £70,248. Not surprisingly, the customer agreed to the repair.

Completed far faster than a new gearbox would have been delivered, the repair meant much less downtime for the customer. The lack of warranty has not been an issue, and ERIKS’ engineers are confident the repair will comfortably ensure several more years of service. The chosen option has also saved a perfectly serviceable asset from scrap, by providing the more sustainable solution of a repair.

Going into overdrive

Following the issues with 5 Roll Secondary Gearbox No. 2 in 2023, and the subsequent repair, the customer approached ERIKS for quotes to repair 5 Roll Secondary Gearbox No. 1 and 4 Roll Secondary Gearbox No. 1.

The manufacturer’s quote for replacing the 5 Roll Secondary Gearbox was £99,103. This compared with ERIKS’ Non-Warranty repair quote of £36,082. Even with shipping and insurance charges added, the customer realised a cost saving of £62,271.

Customer's Gearbox loaded to be sent to the ERIKS Workshop

A new replacement 4 Roll Secondary Gearbox was quoted by the manufacturer at £80,268. ERIKS’ Non-Warranty repair was just £29,809, plus £750 shipping and insurance. So in this case, the customer saved £49,709.

Adding together the repair costs for all three mill gearboxes, and comparing them with the quoted cost for three new replacements, the customer has saved a total of £182,228. In addition, three serviceable gearboxes have been saved from scrap. Consumption of raw materials has been minimised. And CO2 emissions have been reducing, by opting for repair rather than manufacturing from scratch.

Customer's gearbox completed and ready to be shipped back

By showing how a supposedly scrap gearbox can be brought back to life, ERIKS inspired the customer to realise greater sustainability, extended serviceability, and substantial savings on three significant assets.

So the skip’s loss was the customer’s gain.