In this article

ERIKS and Henkel make a firm bond

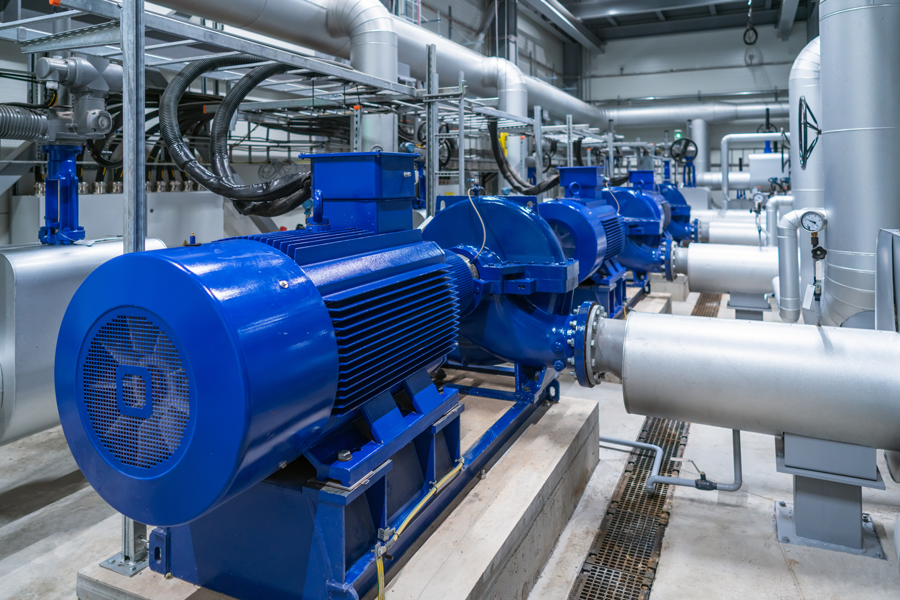

Corrosion, erosion, cavitation and mechanical damage all cause wear to pump castings, impellers and volutes. But they can all be effectively and economically repaired with ERIKS know-how and Henkel’s Loctite® surface engineering products.

ERIKS and Henkel have worked together over many years to repair, improve and upgrade customers’ pumps, and achieve significant savings.

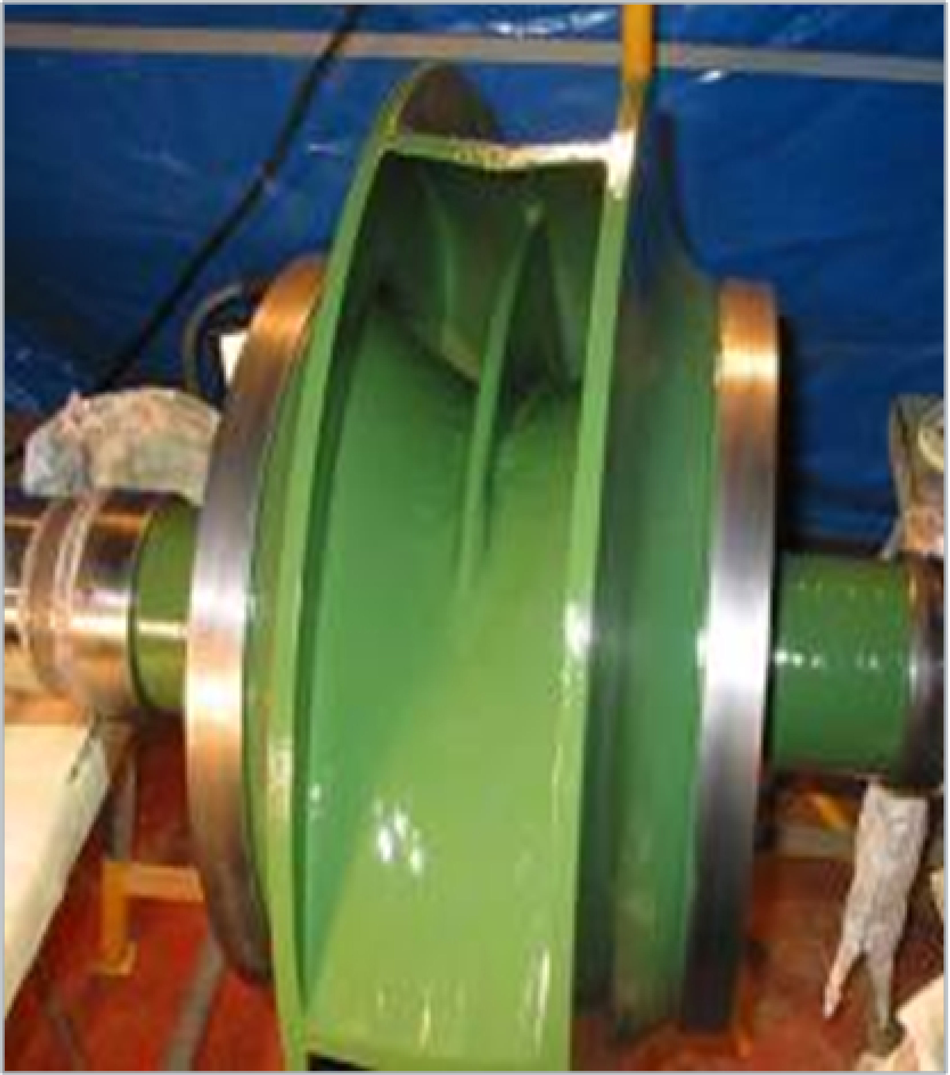

For example, ERIKS evaluated a major UK automotive manufacturer’s 22kW ELPO process water pump as under-performing by at least 30% against the original specification. Dismantling the unit revealed heavy corrosion, a worn, burred and imbalanced pump impeller, seized mechanical seal, and pump/motor misalignment. The volute was cut-water worn, the bearings showed evidence of fretting and corrosion, and the motor was not inverter rated.

7 steps to efficiency

Engineers at ERIKS’ Southampton EMS workshop repaired and restored the pump to efficiency in just 7 simple steps:

- Steam clean components to remove residue and salts before coating with Loctite® polymer composites

- Blast parts to 75 micron surface roughness

- Treat substrates with Loctite® 7515 to prevent corrosion and improve adhesion between metal parts and polymer composites

- Apply Loctite® 7118 as a “hold coat” to smooth surface imperfections and provide a key for thicker layers which return the pump to its original dimensions

- Replace thickness lost to wear, with a ‘build coat’ of wear-resistant Loctite® 7226

- Apply Loctite® 7118 over Loctite® 7226 to create a very smooth finish – reducing friction within the pump and improving energy efficiency

- Fit new bearings and oil and mechanical seals, dynamically balance the impeller, and reassemble the pump with a new 22kW high-efficiency motor. Fit motor and pump to bedplate, and laser-align.

Building back better

ERIKS’ remedial work restored the pump to its original specification, increasing its efficiency by 30%. The repair cost was £5,542, but this was largely offset by a reduction in energy costs of £3,936 in the first year alone.

Under the Government’s Enhanced Capital Allowance scheme for investment in energy-saving equipment, the customer also reclaimed £585.90. So the real cost of the repair was just £685. Long-term savings of carbon emissions (28 tonnes over 5 years) and energy 51.90MWh) will total £19,680 – on one pump alone.

Protect and save

Loctite® polymer composites, coatings and compounds protect parts against attack. Formulated with ceramic fillers for excellent wear resistance and superior adhesion, they can create a sacrificial and renewable working surface, protecting the structural integrity of the original substrate.

Suitable for all surface sizes, and with none of the heat stress associated with traditional methods, they are able to:

- restore worn surfaces on old parts

- extend part life on new products

- protect against abrasion, erosion and corrosion

- resist chemical attack

- increase component efficiency

- save replacement costs

- reduce spare part inventory.

The Loctite® range provides a choice of grades – for fine particles through to coarse – in brushable, sprayable and trowelable formulations, with typical temperature resistance from -30◦C to +120◦C across the range. (Special grades can be used up to 230◦C.)

Loctite® PC 7118 ceramic wearing compound, for example, conforms to KTW guidelines and for direct contact with cold, potable water. It can be used to protect against wear and corrosion for any industrial device carrying potable water. At the same time, it provides high vertical sag resistance and very high abrasion resistance.

Or for use on lining tanks and chutes, heat exchangers, condensers, cooling pump impellers, rudders and pintle housings, there’s Loctite® 7255 energy-efficient coating. With WRAS UK approval, this ultra-smooth, ceramic reinforced epoxy provides a high gloss, low friction coating to seal and protect.

But don’t just take Henkel’s word for it. A Humber refinery reported an 8% energy saving resulting from application of this coating.

For more information on Flow Control solutions and to get in touch with one of our ERIKS Pumps Specialists or Valve/Flow Control Engineers, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Loctite #Henkel #Solutions #Pumps #Coatings #Engineering #Adhesives