In this article

Where sustainability goes hand-in-hand with safety gloves

What would you expect the priority to be for a world-leading company in the safety industry? Safety, of course. But at Ansell, safety goes hand-in-hand with sustainability. The company has recently refined its sustainability efforts to align with the Sustainable Development Goals (SDGs) established by the United Nations. By prioritising the three environment-related SDGs most aligned to the business (Clean Water and Sanitisation, Affordable and Clean Energy, and Responsible Consumption and Production), Ansell aims to reduce its environmental impact without compromising product performance.

As a manufacturer of safety gloves, Ansell is well aware that the majority of a glove’s carbon footprint comes from manufacturing, and the smallest impact from end-of-life glove and packaging waste. So the greatest positive impact on the environment can result from responsible manufacturing and enhancing the sustainability of manufacturing plants: using green energy, conserving water and reducing waste to landfill.

Over the past year, Ansell has invested in refining manufacturing processes, particularly in its Portugal plant.

Thanks to the installation of solar panels, and a Green Power Purchase Agreement with Energias de Portugal, 100% of the electricity consumed at Ansell Portugal is now from renewable sources. These actions have reduced the facility’s greenhouse gas emissions by 900mt CO2e (compared with FY18) – representing a 37% reduction of the scope 1 and 2 emissions inventory of the facility.

At the same time, the in-house water treatment plant has been expanded, and a reverse osmosis-based water recycling system installed. Now that all wastewater can be processed, there has been a 55% reduction in water withdrawal.

Ansell’s Portugal plant is also playing a part in the continuing expansion of the company’s range of ‘Made in EU’ products. This helps to reduce the amount of transportation required, while dual sources of supply help mitigate the risk of unforeseen interruptions, and improve time-to-market in Europe.

Slimmed-down waste

Ansell’s investment in a new dipping line is clear proof that safety and sustainability can work together.

The line, used for the application of the Ansell patented FORTIX™ technology, produces new and improved FORTIX™ products incorporating a breathable, ultra-thin nitrile foam coating for knitted gloves. This not only enhances their abrasion resistance but also lengthens their life – helping to reduce waste.

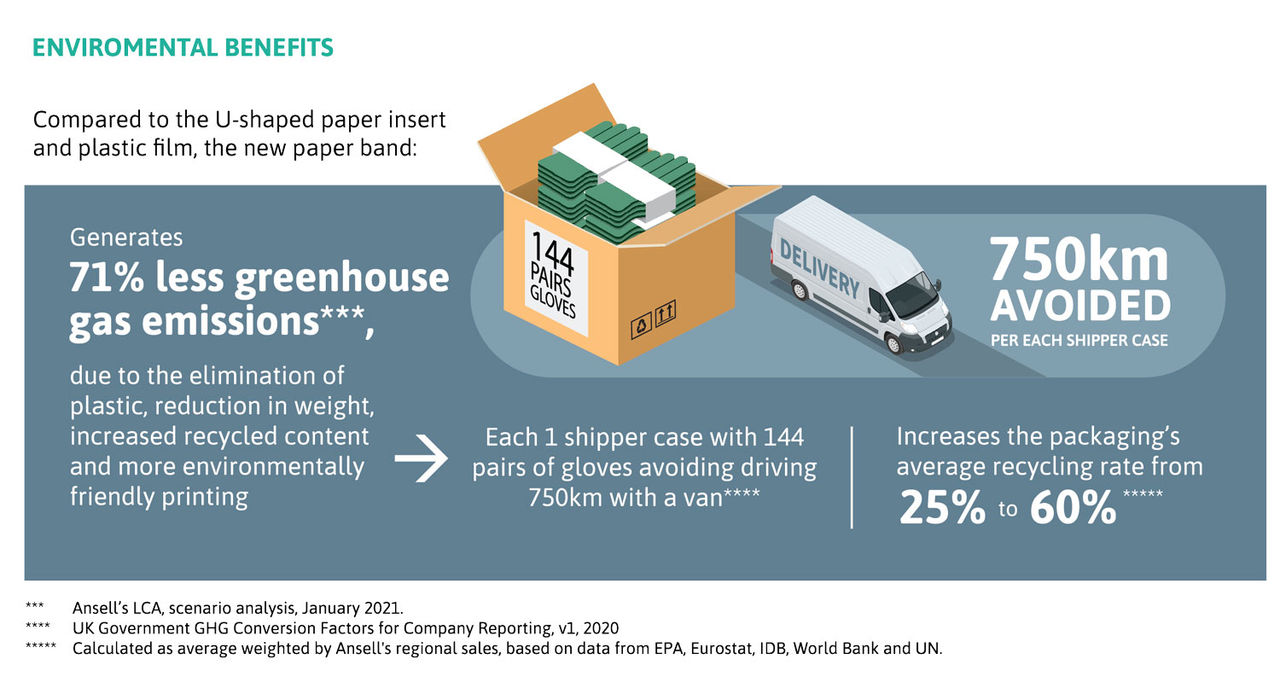

Reducing waste, eliminating plastic and minimising environmental impacts are also the reasons behind changes to the packaging of Ansell HyFlex® gloves.

Previously packaged 12 pairs at a time, using a paper insert covered in a plastic film, one shipper case configuration of 144 pairs of gloves represented an average of 102g of plastic and 239g of paper packaging. Since March 2022, plastic-free packaging on a range of industrial gloves has introduced a newly-designed paper band to replace the previous paper and plastic band.

The new band is fully recyclable, made of responsibly sourced and certified paper, and contains 100% post-consumer recycled content.

A big hand for green gloves

The HyFlex® 11-840 glove has long been Ansell’s most popular multi-purpose glove. Now the HyFlex® 11-842 version deserves a round of applause for going green.

Made sustainably using recycled yarns, and packaged sustainably using responsibly-sourced and 100% recycled paper, the HyFlex® 11-842 sets a new benchmark for sustainable PPE solutions.

Sustainable design features include 90% recycled nylon yarn* liners, plastic-free inner packaging containing 53% fewer materials**, and a carbon footprint reduction of 75g CO2eq per pair^. They are also non-latex, and Dermatest® dermatologically tested to guarantee they are free from harmful substances.

The resilient polymer formulation in the coating, together with the new and improved FORTIX™ technology, provides an extended working life, enhanced durability, and superior fit for precision handling. There’s also up to 20% greater abrasion resistance^^ for workers in a wide range of applications. The touchscreen-compatible gloves are equipped with ZONZ™ Comfort Fit technology, to help improve breathability and dexterity, provide all-day comfort, and reduce the need to remove them when switching between tasks.

The HyFlex® 11-842 is also food-approved, silicone-free and OEKO-TEX® Certified. Making it an excellent universal working glove that not only protects workers, but the environment too.

* minimum recycled content of more than 30% in the final product (based on size 9)

** vs. standard nylon multi-purpose gloves

^ 71% less greenhouse gas emissions – Ansell’s LCA, calculated as weight reduction, peer reviewed

^^ vs. previous technology version

For more information, contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Ansell #ERIKS #LetsMakeIndustryWorkBetter #SafetyGloves #Sustainability