In this article

Clean and Green: Revolutionising Sustainability in Cleanroom Consumables

Manufacturing in a clean environment doesn’t leave room for compromise. Either the environment meets and maintains the necessary ISO 14644 cleanroom standard, or it doesn’t. And if it doesn’t, then the end product won’t make the grade. But with the increasing industry-wide focus on sustainability, manufacturers are looking for alternatives to the high waste, large carbon footprint and excessive consumption of traditional clean environment solutions. Ansell has answers that protect people, products – and planet.

For pharmaceuticals, microelectronics, medical devices and many other products, manufacturing must take place in a cleanroom environment. And the greatest threat to the integrity of that environment is the people who work within it. Contamination – often in the form of particulates – can all too easily be introduced if workers fail to wear the appropriate PPE.

From disposable garments to gloves, goggles and facemasks, it’s essential to select and wear the correct apparel in a cleanroom environment. And if it can help the wider environment at the same time, then everybody benefits.

Hand-in-glove with sustainability

Gloves are a key piece of PPE in a clean environment. The correct gloves will protect the product, the process and the environment from a variety of contaminants, which can range from particles and fibres to static.

They also work in two ways: protecting not only the environment from contamination by the wearer, but also the wearer from contamination or harm from the environment. Depending on the product being manufactured, and the manufacturing process, the wearer could potentially be exposed to chemical or biological hazards, for example, which carefully selected gloves can help protect against.

By their nature, cleanroom gloves are classified as consumables, as single-use is essential to maintaining their cleanroom suitability and integrity. Ansell gloves for cleanrooms are processed using de-ionised water and packed in a cleanroom in non-linting plastic packaging. Through its Ansell Earth sustainability initiative, Ansell has also developed other PPE solutions which minimise their impact on the wider environment.

Packed with environmental advantages

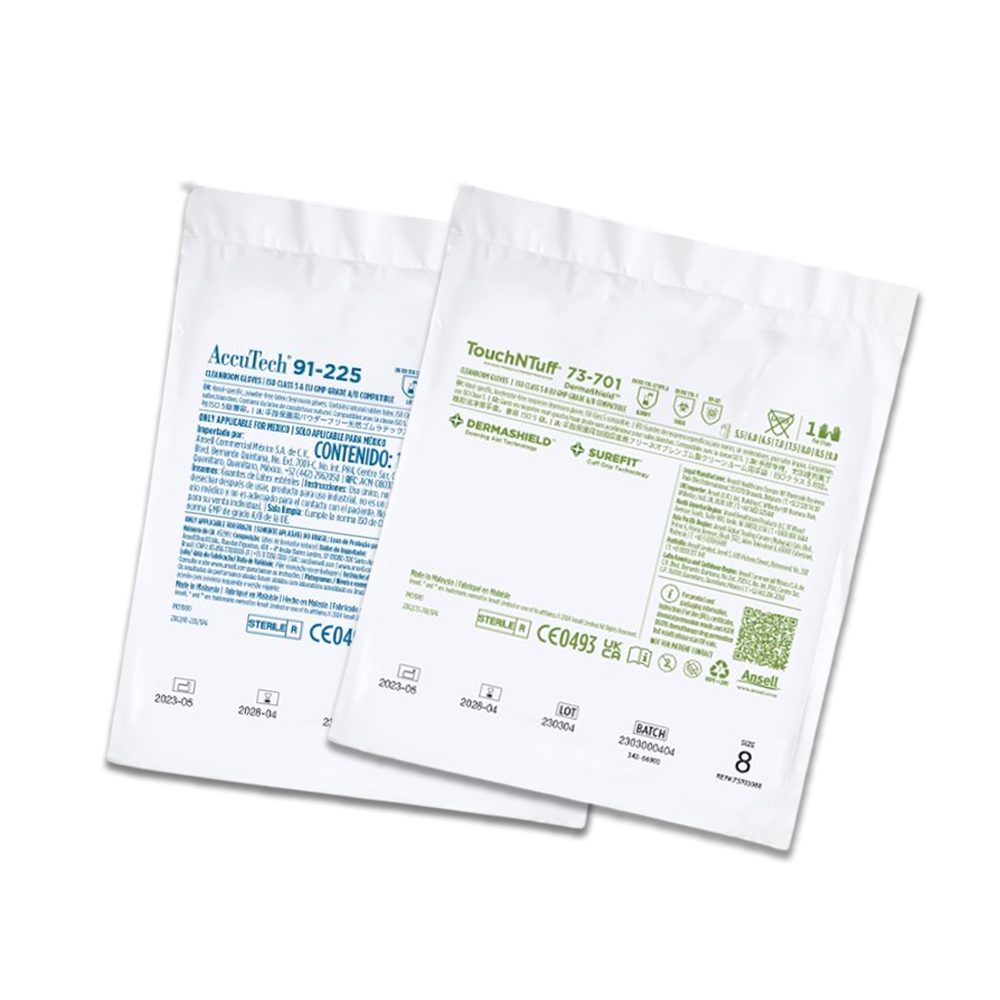

Two of the most widely-used Ansell gloves – the AccuTech® 91-225 and TouchNTuff® 73-701 are now packaged in innovative, sustainable, SMART Pack packaging.

Firstly, the packing process has been automated to minimise human contact and reduce contamination risk. Secondly, the packing pouch size is now 56% smaller than previously – reducing consumption of packing materials. Traceability information is now inkjet printed along the bottom of the pouch, replacing paper barcode labels.

And because the packaging size has been reduced, the same number of gloves can be packed in a smaller space for shipping – reducing delivery journeys and cutting the carbon footprint of shipments.

The box-out below details the reductions made across CO2 emissions, plastic and waste thanks to the SMART Pack packaging alone, which is just one small part of the Ansell Earth initiative.

Guarding against contamination

Ansell has 125 years of experience in PPE, available to you through the AnsellGUARDIAN® consultation service.

This service assesses your operations in relation to your PPE requirements, across seven functional areas: injury prevention, cost reduction, standardisation, SKU reduction, control (dispensing, usage and disposal), training and waste reduction.

To find out more about a free-of-charge AnsellGUARDIAN® assessment of your operations, or about Ansell PPE for your manufacturing environment, contact your usual ERIKS representative. Because your clean environment isn’t the only environment you’ll be helping.

Cleaning-up our act

You can find information about the environmental impact of our products and our sustainability efforts such as our Smart Pack packaging under our Ansell Earth initiative on our website. Through the SMART Pack packaging innovation alone, Ansell has:

- Reduced CO2 emissions from shipments, from 63 tonnes CO2 eq. to 41 tonnes CO2 eq**. That’s the equivalent of 73,340 fewer miles driven annually by delivery vans***.

- Saved 102,187 grams of plastic per year, through reducing the size of packaging pouches. That’s the equivalent of 8,175 plastic water bottles^.

- Eliminated almost 1,000,000 plastic bags annually** by changing the packing configuration of the SMART Pack packaging, from 10 pairs per PE bag to 25 pairs per PE bag

- All SMART pack packaging components are recyclable, including 100% recycled content cardboard shipper cases, and pouches, inner and outer bags made from recyclable HDPE or LDPE*.

- Increased glove pairs per shipment by 18%, which reduces the number of shipments required – cutting emissions still further†.

* Always check your local recyclable status of HDPE and LDPE as these plastic materials may not be considered suitable for recycling in your country.

** Based on FY22 sales volumes (styles 91-225 & 73-701 only).

*** UK Government GHG Conversion Factors for Company Reporting, v1, 2021, average emission conversion factors for delivery van up to 3.5 ton (diesel).

^ Average 500ml plastic water bottle weighs 12.5grams.

† Based on current 73-701 shipper case weight vs. SMART pack 73-701 shipper case weight.

For more information, contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Ansell #ERIKS #LetsMakeIndustryWorkBetter #Sustainability #AnsellEarth #AnsellGuardian