In this article

What's the safest way to verify the absence of voltage?

Industrial environments pose many threats to employee health and safety, and electrical current is one of those right at the top of the list. It goes without saying that exposure to electricity can have catastrophic consequences, so protecting your team against such dangers is vital. Let's introduce you to Panduit's Verisafe...

So, would you like the reassurance that your onsite personnel are safely entering panels without the risk of voltage still being present? We know the answer… of course you would.

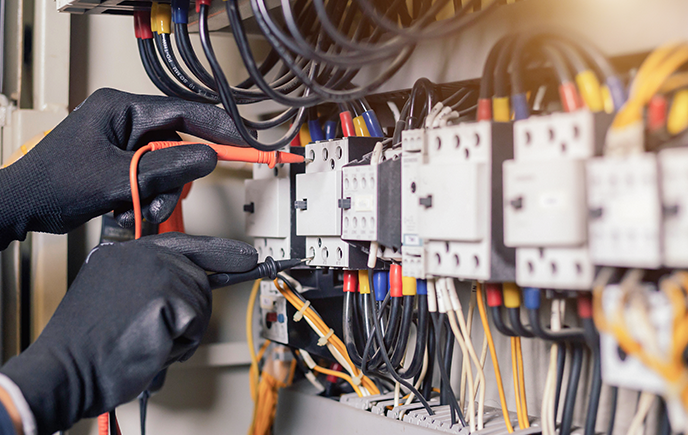

When servicing electrical equipment, engineers must comply with safety regulations that require a voltage verification test to validate the absence of voltage. This process includes a number of stages that can be complex and time-consuming when using handheld portable test instruments.

Previously, engineers would be required to: select the tester, test the tester, test for voltage, and retest the tester before performing the task at hand. But now, thanks to the VeriSafe™ from Panduit, this frustrating procedure has been simplified by automating the voltage verification process.

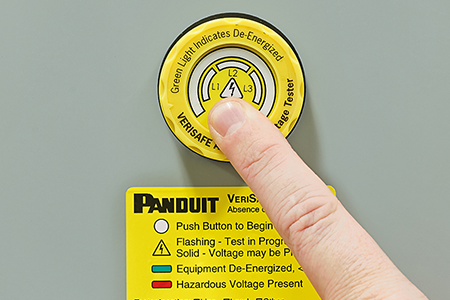

At the push of a button

Once installed, a simple push of a button enables workers to verify the absence of voltage and see an active indication when the absence of voltage is confirmed. This provides a new and innovative way to safely, reliability, and efficiently verify the absence of voltage before accessing potentially dangerous electrical equipment in a fraction of the time compared to traditional hand-held test instruments.

By automating the process, through an externally mounted tester that provides a visual indication of the absence of voltage prior to access, VeriSafe™:

- Reduces the risk of exposure of electrical hazards for improved worker safety

- Reduces testing procedure time and complexity to improve productivity

- Supports compliance when used to verify the electrical lockout/tagout process as described in NFPA 70E

Put to the test

Recently, Panduit and ERIKS engaged in the first onsite demonstration of the Verisafe Absence of Voltage Tester at one large interior lining systems manufacturer, and they haven’t looked back since.

Utilising ERIKS’ onsite relationship with the customer, what began as a simple one-to-one demonstration quickly evolved into a group format, as more and more engineers joined the discussion to uncover how this innovative product could drive both safety and efficiency benefits.

During the open forum, a number of technical challenges were proposed, and an agreement for a two-site trial was presented. Since the initial engagement, the customer has installed a large number of Verisafe across multiple sites and has widely acknowledged that its introduction has increased safety in the isolation of electrical panels.

A representative of the customer commented: “From the initial demonstration through to implementation of the Panduit VeriSafe into the onsite isolation standard, I am proud to say that we have not only increased safety but have also been able to demonstrate efficiency cost savings to justify the investment in rolling out the VeriSafe product across multiple locations.”

For more information on Safety solutions, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Panduit #ERIKS #LetsMakeIndustryWorkBetter #PanduitVerisafe #Verisafe #Voltage #VoltageSafety #VoltageVerifying #ElectricalSafety