In this article

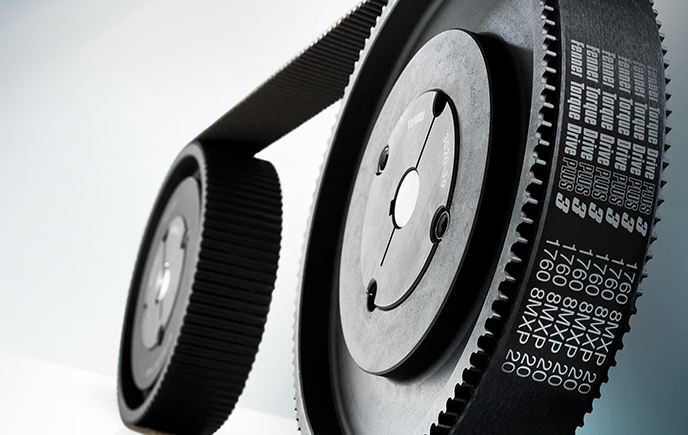

Advantages of Timing Belts: A Question of Belt Timing

Though friction belts are the traditional choice, engineers are coming to realise that timing belts have several advantages. Friction belts and pulleys wear during use, so need re-tensioning 3-4 times during their average three-year lifetime. Each re-tensioning results in downtime.

Conversely, Fenner® Timing belts can be fitted, tensioned, and forgotten. They never need re-tensioning and maintain 98-99% efficiency for their design life.

For new applications, it can make financial sense to choose timing rather than friction belts. However, if you’re already using friction belts in an existing application, can you justify the cost of changing to timing belts?

Three times better

Belt drives are relatively low-cost, easily replaceable, yet crucial components. It’s essential to specify the correct belt for the application and the operating environment, to reduce the risk of failure and optimise performance.

Specify the wrong belt and even installed correctly and maintained perfectly it won’t perform efficiently or offer a long service life.

Fenner® timing belts offer three key advantages. Firstly, reliability. Secondly, excellent performance. And finally, efficiency. They also offer specific advantages for applications.

For example, a food and beverage manufacturer was having difficulties with repeated failures of a chain drive. Oil on the chain caused hygiene issues, frequent washdowns washed out the lubrication and the wide temperature variations within the factory were causing problems.

Switching to a timing belt solved all the problems: reducing breakdowns and maintenance while lowering noise levels.

Fenner® timing belts are better suited than chains to high humidity, or arduous, dusty environments such as quarries or flour mills.

Payback time

Converting your friction or chain drives to timing belts is straightforward. A drop-in replacement will immediately start to improve efficiency, as well as eliminating re-tensioning work. If you choose a timing belt you will also need to replace the pulley – but that could lead to additional gains. For example, one timing belt can deliver the same power as five friction belts, saving on pulleys and space.

In most cases the minimal maintenance costs, reduced downtime and lower energy requirements should provide payback in just 3-4 months. The quieter running of a timing belt also leads to a better working environment.

But whether you opt to save money and increase efficiency by choosing Fenner® timing belts, or you stick with friction belts, be sure to follow the Best Practice outlined below to optimise their efficiency.

Getting the best from belts

- Never fit a new belt on a severely worn pulley. It will last less than 1,000 hours compared to its 25,000 hours design life.

- Slacken the tension when fitting the belt. Never lever it on with a screwdriver or crowbar, as this risks damaging the belt and drive.

- Belt tension is critical to efficient performance. Check belt deflection at installation.

- For friction belts: fit, tension, run for a short period, then recheck and re-tension if required.

- Replace timing belts after 24,000 hours for maintenance-free operation.

For more information you can contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Fenner #TimingBelts #Upgrades