In this article

Drive belt performance to get your teeth into

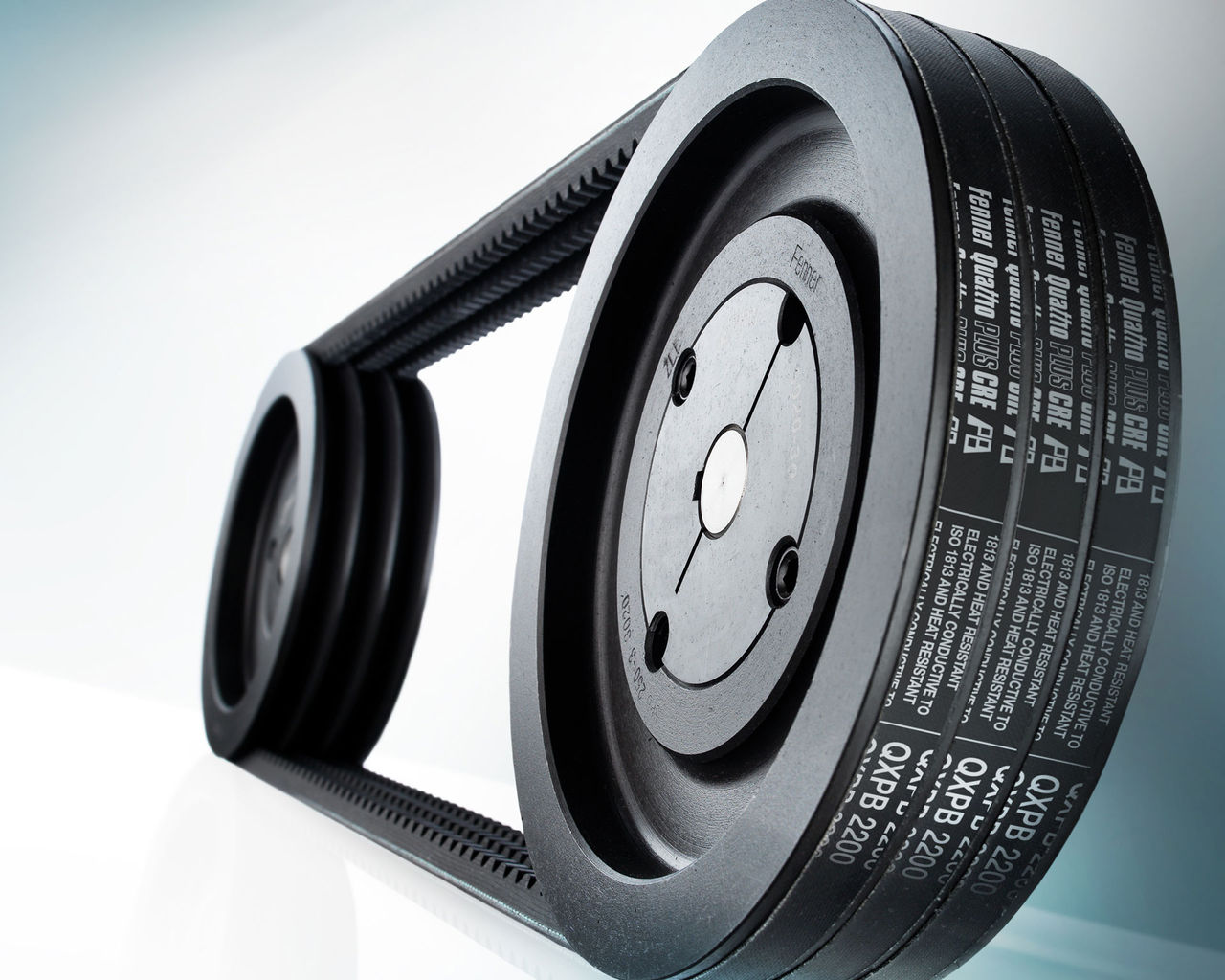

All drive belts transfer power. Some transfer more power than others. Thanks to its advanced materials, unique construction and enhanced tooth profile, the Fenner® Quattro PLUS CRE wedge belt transmits 26% more power than its predecessor. But that’s not its only plus point.

Power, PLUS…

As well as transmitting more power to your application, the Fenner® Quattro PLUS CRE does it with greater efficiency: 98% compared with 96% efficiency for a standard belt. So – especially in applications operating 24/7 – it helps to reduce the Total Cost of Ownership (TCO). It also operates happily in temperatures as low as -40°C and as high as +130°C.

And the greatest advantage of all is that, because it extends belt life by as much as 15%, it does all this for longer.

So what makes this belt such a significant advance in power transmission technology?

Construction, PLUS…

The tension member of the Fenner® Quattro PLUS CRE belt has a unique construction, which improves the accuracy and stability of the belt length.

The contact section is manufactured from EPDM synthetic rubber, to improve the power transmission. The abrasion-resistant compound used in the belt’s manufacture enhances durability and lengthens service life. And the enhanced tooth profile not only improves the flexibility of the belt, but also reduces its bending resistance – which in turn increases its efficiency and service life.

However, all this added engineering technology doesn’t add up to a heavier belt. In fact the Fenner® Quattro PLUS CRE is lighter than other Quattro options – making it a heavy-duty performer but not a heavyweight belt.

This lighter weight also helps to reduce vibration, which leads to smoother running and fewer associated stresses on the transmission system.

Maintenance-free, PLUS

The design and construction of the Quattro PLUS CRE gives it a lower pre-tensioning force, and greatly extends the length of time before retensioning is required. Once fitted to the manufacturer’s specification, it can be tensioned, run-in, retensioned, and then left to run maintenance-free in most applications.

By lowering the pre-tensioning force required, the Quattro PLUS CRE also helps to extend bearing life, which further reduces maintenance downtime and costs. And because the belt is conditionally oil resistant, it can shrug off the effects of oil introduced during its operation.

Precision, PLUS

Fenner® PB* (Precision Build) technology ensures accuracy and consistency in the manufacture of the Quattro PLUS CRE belt. So even when you choose belts from different batches, you can be sure that the length, strength, weight and performance will be the same across every belt you fit.

Which means you can rely on your power transfer not just hour after hour and day after day, but belt after belt too.

And if you fit the Quattro PLUS CRE in a complete Fenner® drive train package – incorporating Fenner Taper Lock® Pulleys and Fenner® Taper Lock® Bushes – you can expect optimum performance, reliability and belt life.

Applications, PLUS

The operating temperature range, bending resistance and unique construction of the Fenner® Quattro PLUS CRE make it ideal for a wide range of applications.

It is especially recommended for:

- Fans, compressors and pumps

- Printing machines

- Textile machinery

- Packing machines

- Elevators

- HVAC and blowers

Conforming to a wide range of international standards – including BS 3790, ISO 4184 and DIN 7753 – you can also be assured that it’s tried, tested, and approved.

So why settle for standard drive belt performance, when you can have Fenner® Quattro PLUS CRE performance?

Case Study: A cure for secondary cure

When a drive belt becomes overheated during operation – due to ingress of dust from the operating environment, for example – it can lead to a secondary cure of the belt material. This makes the belt unstable and more likely to snap.

For one customer, operating in a particularly dusty environment, belts were lasting an average of no more than six months. Fitting Fenner® Quattro PLUS CRE belts extended belt life to at least twelve months.

The lower cost of the Fenner® belts, plus their longer service life between replacements, and reduced labour costs for maintenance, saved the customer a total of £919.16 per annum.

For more information on Power Transmission and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Fenner #ERIKS #LetsMakeIndustryWorkBetter #QuattroPlusCRE #DriveBelts #Efficiency