In this article

Aye, Aye, Capstan

When one of the Royal Navy’s warships needs maintenance, it pops into dry dock. But when you’re manoeuvring something which weighs tens of thousands of tonnes, perhaps ‘pops’ isn’t the right word. That’s why powerful capstans are used to haul the mooring ropes that move and secure the ships in the docks. And why those capstans need to be ready, reliable and shipshape.

With only nine functioning capstans for sixteen locations, one naval dockyard was frequently lifting and transporting these large, heavy mechanisms – which was doing them no good at all. Their engineering partner decided they needed help with finding a solution. Naturally, they called ERIKS.

All hands on deck

It’s rare to find a straightforward engineering problem. Many of them involve a range of issues that need a breadth of expertise and experience, plus an understanding of applications and operating environments. In short: most problems need know-how.

In this case, once ERIKS had reviewed the issue and assessed the challenge, it was obvious that a breadth of component knowledge and engineering skills was required: from gearboxes to seals and from polymers to power transmission.

With the combined know-how of ERIKS’ Gearbox Centre of Excellence in Pensnett, ERIKS Engineering Service Centre in Cardiff, and ERIKS Sealing and Polymer product specialists, it wasn’t long before ERIKS Power Transmission Application Engineers and Project Engineers had worked out a plan to help get the capstans back on the road and the ships back on the sea.

Bearing the weight

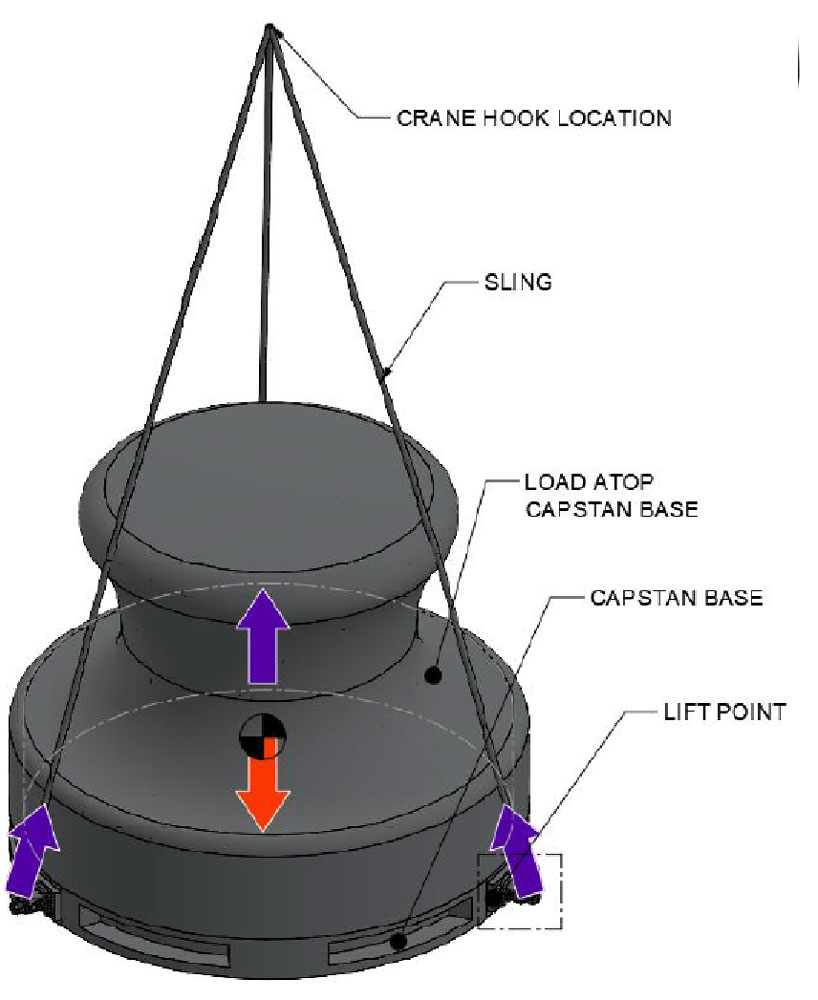

The capstan is designed to pull and let-out rope, and has a handling capacity of up to 16 tonnes, while the capstan itself weighs 5.5 tonnes. Though never designed to be relocated, by lifting the capstans with a crane and a sling around the main unit, and letting the slew bearing arrangement taking the bulk of the strain, the customer was managing to shift them around the dry docks.

The offset motor added an extra complication, as it meant that the load skewed from the vertical as it was lifted – making it even more awkward to transport and extremely hard to reposition once moved. Clearly ERIKS’ engineers needed to find a new lifting solution.

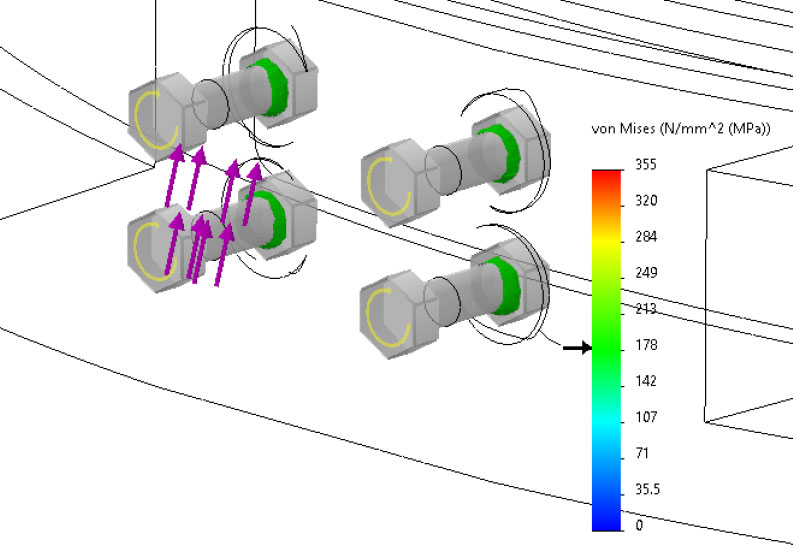

The task began with extensive structural calculations, followed by 3D scanning and design, material analysis and Finite Element Analysis. With all the necessary facts and figures to hand, ERIKS’ engineers safely modified the base of two capstans, to accommodate new lifting points – eliminating the tilt and skew resulting from the previously unbalanced lifting.

Now ERIKS’ engineers turned their attention to giving the capstan mechanism itself a lift.

Full steam ahead

The age of the capstan design meant it was more than ready for an overhaul, to optimise efficiency and ensure compliance with all the latest regulations. There was also an opportunity to replace bespoke components with off-the-shelf alternatives, to reduce repair and maintenance costs.

After ERIKS had machined and installed a number of new large components, the complete unit was lift-tested and certified for safety by an accredited external authority.

Next, the gearbox mechanism and motor demanded an overhaul. Firstly, all internal gearbox components were closely inspected for wear and tear, including Non-Destructive Testing of the gear teeth. All roller bearings were then replaced, together with the bespoke 17’ hollow square section seal.

Worn spur and single helical gears were also swapped for new reverse-engineered replacements. Once the motor bearings were replaced, along with the anti-condensation heater, the motor windings were Baker Surge Tested to ensure they were free from weaknesses and incipient faults.

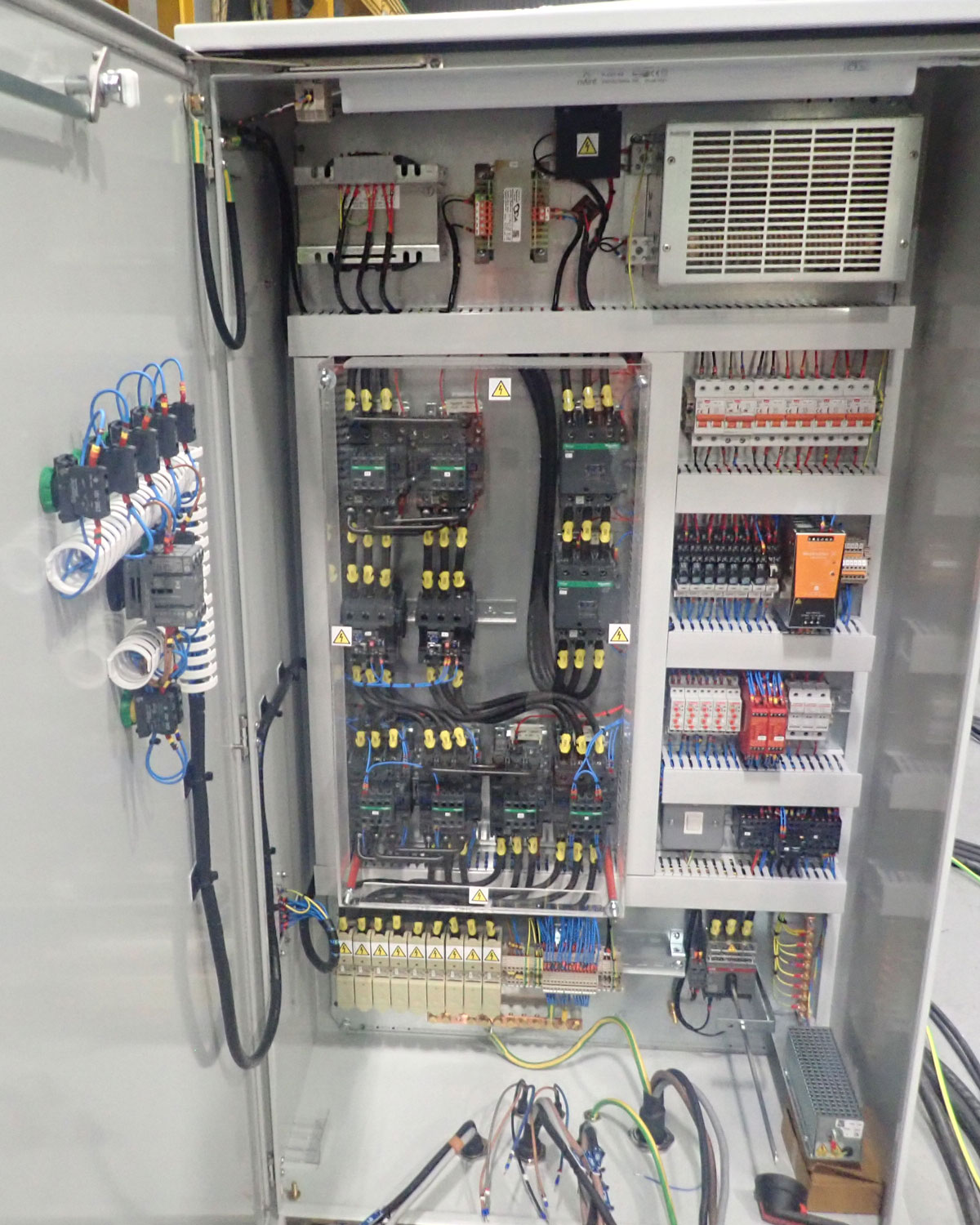

As the final stage in updating the performance and functioning of the capstans, ERIKS designed a new control panel system incorporating the highest applicable safety standard (BSEN13849-1PLe). The panel was then built by an ERIKS-approved vendor to meet CE and UKCA requirements.

An ergonomic chest pack panel was also developed, to enable mobile control of the capstans. Wherever possible, off-the-shelf components were used to reduce costs, simplify maintenance and repair, and effectively future-proof the system for years to come.

After final testing and commissioning of the improved lifting system and the overhauled and updated capstans and controls, the customer was provided with comprehensive technical documentation – so engineers in the future won’t be all at sea.

ERIKS have now successfully overhauled and returned all six capstans back to site: proving that ERIKS’ engineering and application know-how means they are never out of their depth.

For more information on Power Transmission and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Engineering #KnowHow