In this article

A match for your explosive environments

If your operations include processes in potentially explosive atmospheres, you’ll know the risks and the right precautions to take. But some hazards can be more easily overlooked than others.

Combustible gases, vapours and dust are key ingredients for potential explosions. When you know they’re present, obviously you will take steps such as using specialised ATEX-certified equipment and products. Only these will keep you compliant with international standards, and ensure the safety of your staff, plant and the environment.

However, if there’s been an emergency repair, for example, or a temporary replacement has been installed, there may be non-ATEX-certified products hiding in plain sight in your facility. Motors and hoses, we’re looking at you…

Twice as safe

Motors generate heat, have moving parts, and contain potentially combustible materials. That’s why they’re a serious explosion risk in chemical plants, grain processing facilities, oil refineries and similar environments where explosive atmospheres might be present. But as crucial components for driving many processes, industry literally can’t operate without them.

The only option is to choose motors for hazardous environments which are tested and certified to be as safe as possible.

ATEX-certified motors greatly reduce the risk of adverse events in hazardous environments. “Explosion-proof” or “flameproof” motors in particular have specially designed “flame paths” that cause internal sparks or explosions to dissipate before reaching the external environment.

ATEX motors will usually have increased IP ratings and sealing arrangements to prevent the ingress of potentially hazardous material.

Even so, it’s still important to choose the correct ATEX motor, specifically classified for its operating environment: for example, whether the atmosphere contains gas, dust, or if explosive materials are likely to be present.

ATEX A to B

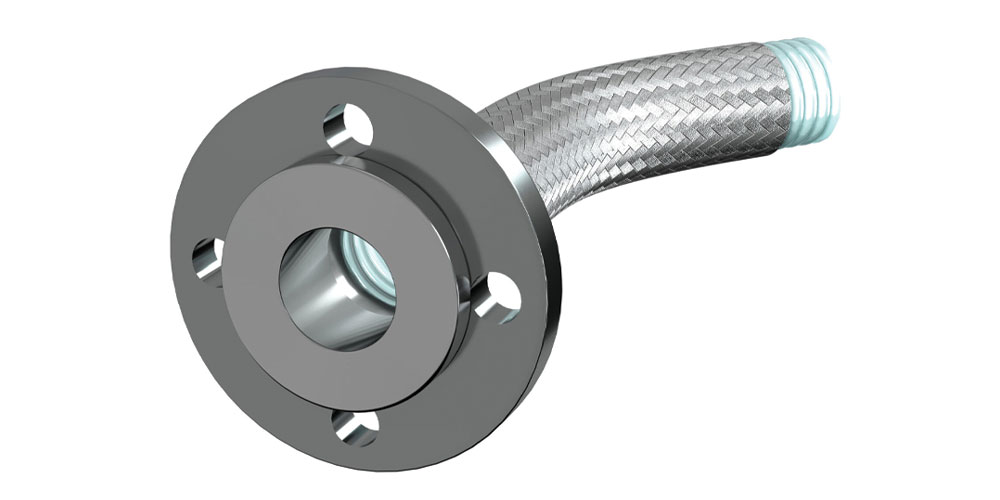

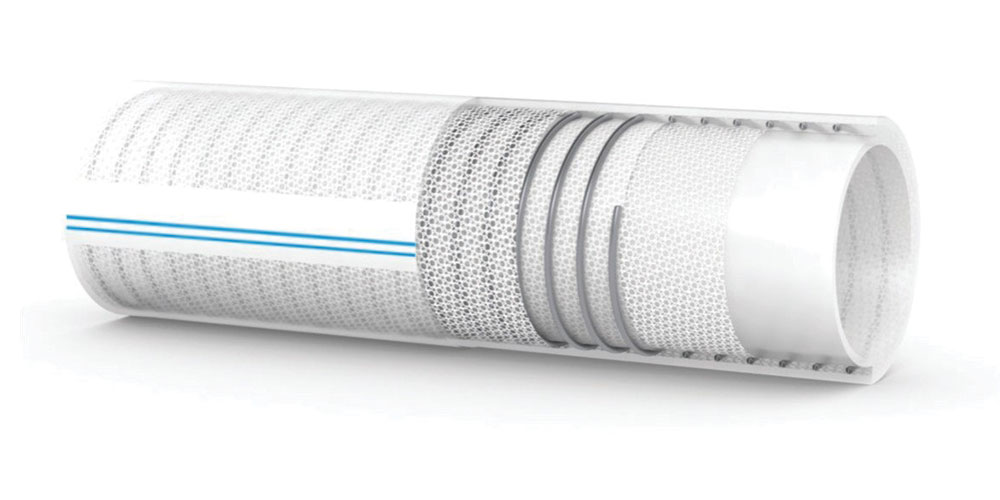

Many processes such as fuel transfer and chemical transportation; require getting liquids and gases from A to B. This is a risk if the liquids or gases are flammable, and/or being transported through external explosive atmospheres. Therefore, the hoses carrying them have to be capable of handling the substances without being affected by them, and must also be resistant to the environment they pass through.

Just like motors, hoses can be ATEX-certified to prove they are resistant to ignition and won’t become a source of ignition themselves. ATEX-certified hoses are also made from materials that are resistant to any chemicals they might be required to carry. In addition, they have antistatic properties to prevent the build-up of static electricity, which can be a potential source of ignition.

ATEX by numbers

There are two key ATEX regulations, which apply to gas, vapour and dust explosions.

The ATEX 114 (2014/34 EU) directive specifies requirements for equipment and protective systems designed for areas prone to explosions. It relates solely to product design and manufacture, so is targeted specifically at equipment and systems manufacturers.

ATEX 153 (1999/92/EC), on the other hand, covers the safe use of equipment and protective systems in explosive environments. It sets minimum safety standards for the workplace and the equipment, to ensure the safety of employees in such hazardous areas.

To help keep your employees safe and your operations compliant, you not only need to look for motors and hoses which meet the requirements of ATEX 114 and 153, but you also need to understand three other key considerations:

- Zone Classification: Equipment should be rated for the zone it will operate in e.g. Zone 0, 1, 2 for gases and Zone 20, 21, 22 for dust.

- Material Compatibility: Equipment materials should be compatible with the substances they will be exposed to. This includes chemical- and temperature-resistance.

- Maintenance and Inspection: Regular checks and maintenance are essential to ensure that ATEX-certified equipment remains in safe working order. Wear and tear or damage can compromise safety.

Safer working starts here

ERIKS’ wide selection of ATEX-certified products is especially suitable for gas- and explosion- hazardous environments. It ranges from motors to valve switchboxes, plastic hoses to wear-resistant rubber hoses, and even includes spark-free tools for maintenance and repair work.

By choosing the right hoses and motors, and working with the right equipment, you can protect employees, ensure compliance, and reduce risk to the minimum at all times.

What does ATEX mean?

ATEX is an abbreviation for ‘ATmosphères EXplosibles’, which is a set of European Union regulations devised to ensure the safety of products used in potentially explosive atmospheres. ATEX-certified products have undergone rigorous testing to confirm they won’t ignite explosive materials.

For more information on Power Transmission or Flow Control solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #ATEX #Motors #Hoses #ExplosiveEnvironments