In this article

This may shock you

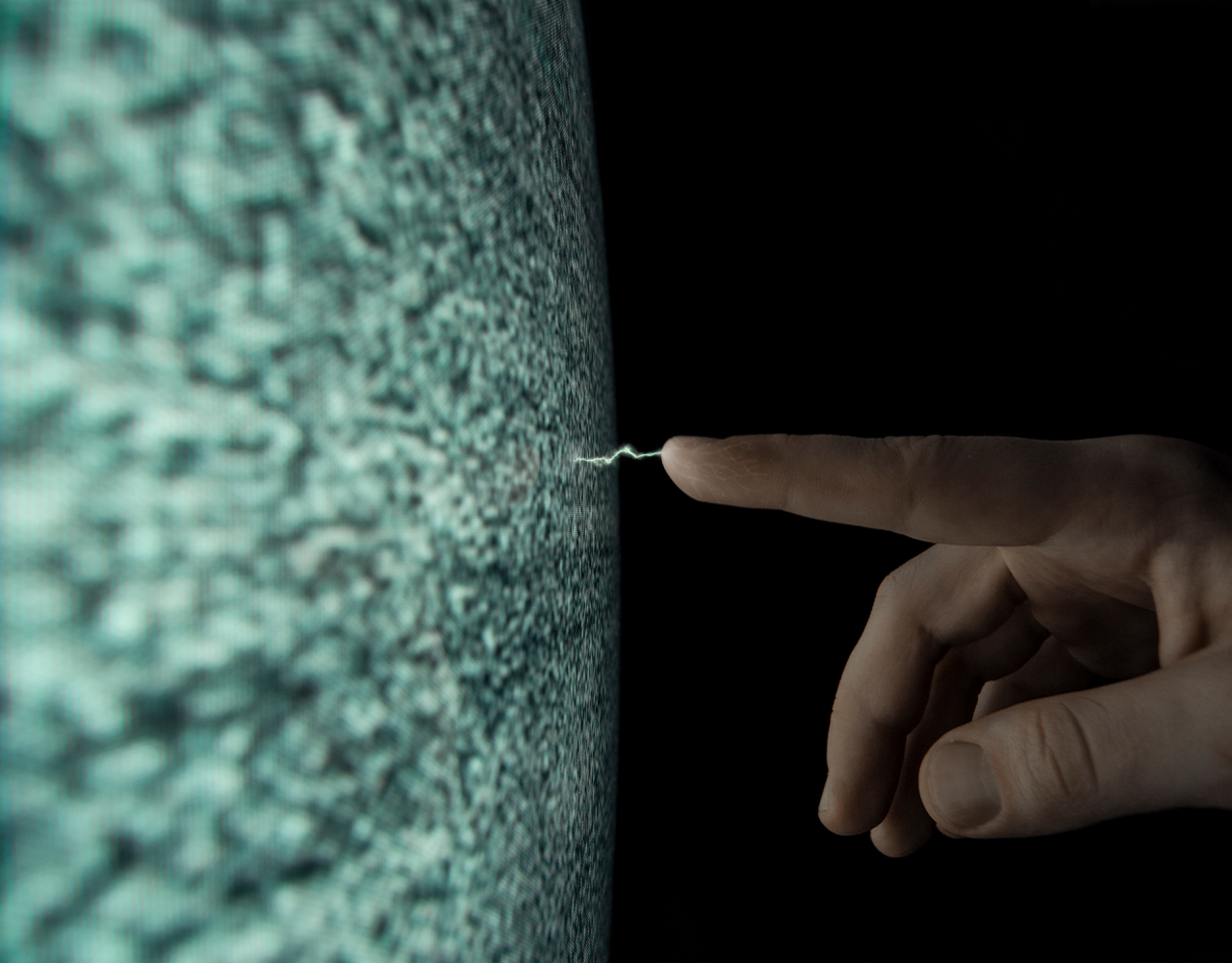

Electricity bills are not the only shock to your system – and your bottom line. Static electricity can give you a jolt, and reduce efficiency and productivity.

There’s a type of electricity which is generated for free but which can still cost you money. It’s probably present on your site, and could already be affecting productivity and product quality. It could even be threatening your employee’s safety.

It is, of course, static electricity.

When there’s an imbalance between negative and positive charges in an object, static electricity can cause problems by its build-up on the object’s surface, and further problems when it finds a route to release or discharge. And it’s more common – and more of a problem – than you may think.

From jams to jolts

A drinks manufacturer experiencing production stoppages on a bottling line thought the sheer number of plastic bottles on the conveyor was causing jams. But investigation revealed that a build-up of static electricity was the issue: making the products unstable on the conveyor, leading to downtime and lost production.

Another manufacturer, whose process involved picking individual plastic sheets from a pile, found that static electricity would often cause sheets to stick together, so that several would be picked up at once – causing production disruption. And a producer of foam sheets, cut from foam blocks, experienced static electricity build-up due to friction between the cutting blade and the block. The cut sheets sticking together increased the cycle time by up to 40%.

These were relatively minor issues – though with a notable effect on productivity. But static electricity can also cause major problems with catastrophic consequences.

Compromised product quality – leading to product recalls and reputational damage – is one. Sparks generated next to flammable substances is another, with obvious, dangerous, and potentially fatal outcomes. Sometimes static electricity can even build up to such a level that it can deliver a sizeable, highly unpleasant shock to any employee who touches the charged item.

So how can you identify whether static electricity is having a negative impact on your productivity? And how can you remove the charge and resolve the problem?

Measure to manage

Static electricity can be generated at many stages of a production process, and in many different locations on a production line. To understand if a problem really is being caused by static electricity, it’s necessary to identify where the charge is being generated, and how powerful it is.

A handheld electrostatic meter of the kind available from SMC can make it quick and easy to obtain accurate information, so that the most efficient solution can be installed where it will have the greatest effect.

Once the location of the problem has been identified, then the next step is to resolve it.

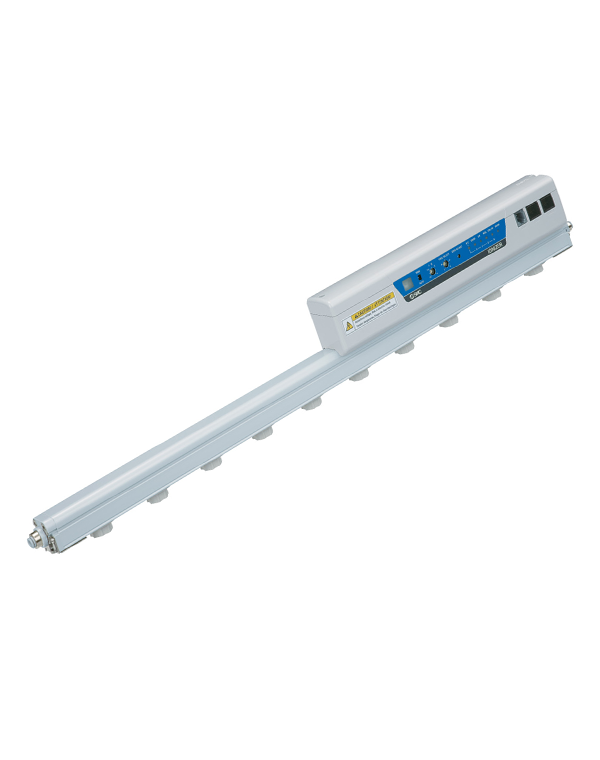

Eliminating the static electric charge requires ionisation. SMC offers a range of ionising devices, making it easy to choose the most appropriate solution for the location of the problem:

- Bar ioniser – integrated, fast and effective static removal

- Nozzle ioniser – local static removal with choice of nozzles to suit the application

- Ionising gun – point, shoot, neutralise

- Fan type – for locations with no compressed air supply

- Desktop duster box – static neutralisation, dust removal and dust collection in a single unit

Once you have identified the cause and location of the static electricity charge, integrating ionisation into your production process is simple. Just choose the most appropriate SMC ionising solution for your location and application, plug it in, and forget about it. Apart from occasional cleaning of the nozzles, ionisers are maintenance-free.

So eliminating static electricity and the problems that go with it can be quick, easy and cost-effective. That’s what’s really shocking.

For more information on Fluid Power, Transfer and Control Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SMC #ERIKS #LetsMakeIndustryWorkBetter #StaticElectricity #IonisingSolutions