In this article

Are you due for an air cut?

If you’re being scalped by energy bills for your compressed air, the new air management system from SMC could stop you tearing your hair out. A revolutionary next-generation solution, the AMS20/30/40/60 series could reduce your air consumption by up to 62% – and cut your bills and CO2 emissions accordingly.

From automotive plants to textile factories, from food to forestry, and from electronics to life sciences, countless manufacturing and processing plants use compressed air as part of their operations. So it’s hardly surprising that badly managed or maintained compressed air systems are a major factor in energy wastage and excessive CO2 emissions across all these industries and more.

Poorly controlled air consumption, undetected leaks, and processes which fail to take proper account of standby and shutdown, all lead to increased costs from wasted energy, as well as higher maintenance and repair costs due to unexpected problems and lack of planned maintenance.

What’s more surprising is the scale of savings available.

Operators of compressed air systems who adopt the new SMC AMS20/30/40/60 air management system for their applications can expect to see a reduction of up to 62% in their compressed air consumption. Which means benefits not only to the bottom line, but also to the environment.

Three solutions compressed into one

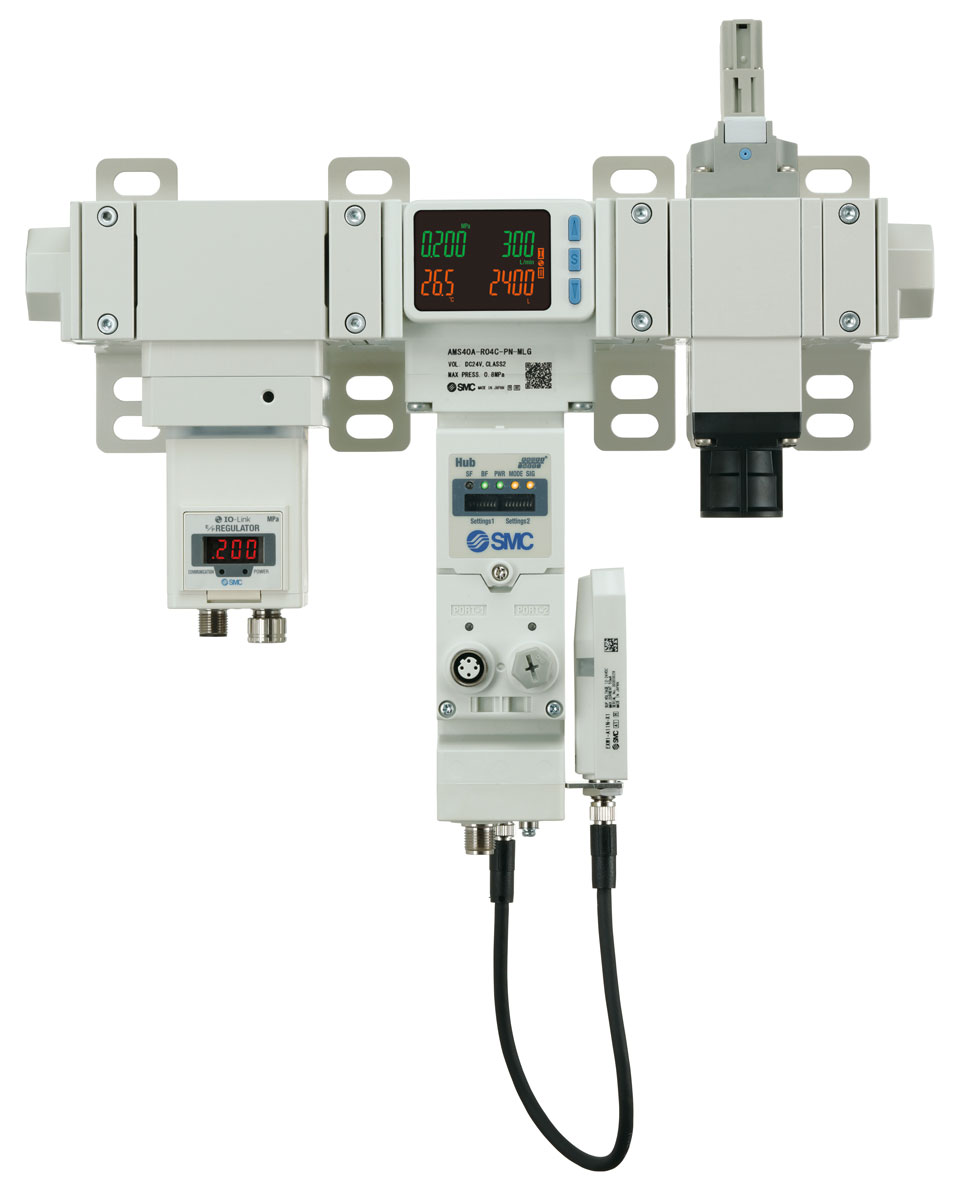

The new SMC air management hub is not just a compressed air regulator. It’s not even a regulator with a residual pressure relief valve. It’s a regulator, residual pressure relief valve and management hub, all in one integrated unit.

The valve enables switching between a secondary air supply and exhaust (switch-off). The standby regulator switches pressure between operation and standby. And the air management hub senses and controls the air flow rate, pressure and temperature.

So as well as using it to monitor air consumption – helping to identify excessive usage and anomalies – customers can use the AMS/20/30/40/60 series to monitor air line pressure and temperature. This allows the establishment of baseline parameters for individual machines and even entire factories, so that preferred operating conditions can be identified.

The data will also help to detect leaks and – by monitoring equipment status – will enable analysis of variations, which can lead to steps to reduce downtime and wastage. Instead of reactive and costly corrective actions, this high-resolution data can be used to define preventative actions and planned maintenance tasks.

This will help to decrease the amount of compressed air that’s wasted, to cut energy bills and reduce CO2 emissions.

Efficiency is in the air

Generating compressed air for equipment that’s on standby or shutdown is simply throwing money away. So the SMC AMS20/30/40/60 series features programmable automatic pressure reduction and shut-off times.

By ensuring you generate compressed air only at the pressure you really need and at the times you really need it, the unit reduces consumption, bills and CO2 emissions and optimises system efficiency.

This kind of control is made possible by the digitalised installation and optional wireless capability of the system. Innovative wireless technology means easier integration, eliminates complex writing and cabling, and reduces the chance of installation errors.

There’s no need for a PLC or edge server, as the decentralised system is compatible with OPC UA for direct data communications, as well as with Ethernet I/P, Profinet and IO-Link devices. Up to 10 remote units can be connected to a single SMC Air Management System hub, over a distance of up to 100m radius.

Rated IP65 or IP67 depending on the regulator type, the SMC AMS20/30/40/60 series units are suitable for use even in harsh environments. They’re also protected against other less obvious external threats, through unique encryption. This provides high security from bugs, hacking and other digital criminal activity.

Not seeing is believing

Because compressed air is invisible, it’s all too easily overlooked. And while air leaks and wasted air can’t be seen, their effect on energy bills can. CO2 emissions are also invisible, but their effect on the environment can’t be ignored.

However, with compressed air consumption reductions of up to 62%, it’s easy to see why all the talk about the SMC AMS20/30/40/60 series isn’t just hot air.

View our range of Pneumatic Components including SMC or for more information on Fluid Power, Transfer and Control Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SMC #ERIKS #LetsMakeIndustryWorkBetter #CompressedAirConsumption #EnergySavings