In this article

Listening to the Voice of The Machine

If you’re familiar with Parker, you know they have been manufacturing components and subsystems for industrial equipment for a long time. One hundred years to be exact.

You also know the world is much different today than it was 100 years ago—or even five years ago for that matter.

One of the biggest recent advancements in industrial manufacturing is the proliferation of sensors on all types of industrial equipment, from connectors, hose and tubing to pumps, motors, actuators and filters. Data from these sensors creates enormous opportunity to transform the way industrial equipment is operated and maintained.

Travelling the Last Mile

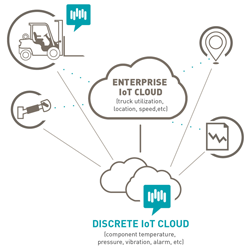

Yet, those opportunities, to date, have largely been unrealized. While much of the focus of Internet of Things (IoT) technology has been on “enterprise-level” IoT systems, these systems are unable to collect data from the component level. To borrow a phrase from telecommunications, industrial IoT has failed to travel the “last mile,” limiting its overall value.

Proprietary protocols, security concerns, and the overwhelming volume of data being generated have all prevented operators from covering this last mile and gaining the insight they need to predict failure and optimise performance at the component level.

That’s where Parker's 100 years of experience comes in. Their depth of technical knowledge gained from working across hundreds of thousands of applications, has been instrumental in their effort to effectively address the challenges of discrete IoT. For example, they know exactly where to integrate sensors for optimal insights, what data to collect, and how to present it to maintenance, repair and operations professionals in the way that is most useful to them.

But experience alone isn’t enough to travel the last mile. Addressing the challenges of discrete IoT also required focus and commitment.

Standardised Communication Standards

Several years ago Parker initiated a centralised strategy to ensure the IoT-Empowered products and subsystems they were developing across their businesses would all use the same communications standards and best practices to deliver interoperability and security.

They also realized that their products must co-exist with products from other manufacturers. One of the core principles of their centralised IoT initiative is “the value of any IoT solution is directly proportional to its interoperability.” They employed an open, exchange-based architecture that enables interoperability with third-party products, applications and platforms. They also worked with the OPC Foundation and the Industrial Internet Consortium to support interoperability across IoT devices and platforms.

Open, Secure and Scaleable

The result is an open, secure, interoperable and scalable ecosystem of connected products and services that help you improve business productivity by unlocking the last mile of IoT. Parker call it "Voice of the Machine™.

For more information on Fluid Power, Transfer and Control Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Parker #ERIKS #LetsMakeIndustryWorkBetter #Machines #IoT #Connected