In this article

Powering Progress in EV Battery Manufacturing

Electric vehicle (EV) manufacturers play a pivotal role in the transition to sustainable transportation. As the automotive industry evolves at pace, production processes must also advance – driven by performance, precision and innovation.

At the heart of this transformation lies the relationship between ERIKS and IMI. Combining world-class motion control technology with deep application knowledge, this collaboration is helping manufacturers navigate complex challenges and deliver exceptional results.

According to the latest data, there are 1.25 million fully electric vehicles in the UK - just 3.75% of the total 34 million vehicles on the road. In contrast, the Climate Change Committee’s target is that 55% of light-duty vehicles should be battery-powered by 2032.

To meet this goal, the entire EV ecosystem must accelerate, and battery manufacturers have a pivotal part to play.

Meeting the demands of a specialised industry

Battery manufacturing is no ordinary industrial process. It imposes exceptionally high standards at every stage - from electrode preparation to module assembly and final testing. Maintaining cleanroom integrity, managing energy use, and ensuring process accuracy are essential.

IMI’s motion control technologies are designed specifically for these exacting requirements, and with ERIKS’ engineering support, manufacturers can confidently specify, integrate, and maintain the right solutions.

Through their supply ERIKS provide trusted expertise, technical consultancy, and hands-on service. Helping customers make informed choices, reduce downtime, and improve production line efficiency through proactive engineering and support.

The EV market is fiercely competitive. Speed, accuracy, and quality are all essential - not just for delivering superior products, but also for reducing energy use and production waste.

IMI’s solutions are engineered for durability and efficiency, delivering long-term reliability even under demanding operating conditions.

Engineered for Cleanroom Compliance

Cleanroom environments are non-negotiable in EV battery production, particularly during electrode mixing, coating, and drying, as well as cell assembly. IMI Norgren’s components meet cleanroom classifications 1 to 9 (ISO 14644-1), with actual testing showing compliance from ISO Class 4 to 7.

These credentials ensure compatibility in both dry and cleanroom areas - crucial to avoid contamination, maintain product integrity, and meet compliance standards.

With the support of ERIKS, customers also benefit from on-site technical expertise, product specification support, and ongoing condition monitoring. Whether it’s helping to align motion control systems with airflow standards or offering predictive maintenance strategies, ERIKS ensures that IMI’s technology is applied in the most efficient and productive way.

Partnership that powers progress

From standard components to bespoke solutions, IMI’s portfolio of IMI Norgren products support all stages of battery production.. But it’s the partnership with ERIKS that brings these solutions to life on the factory floor.

Our shared focus on innovation, compliance, and performance ensures that customers benefit from a seamless, joined-up approach - combining the best of product and process.

By collaborating from the ground up, ERIKS and IMI are not just solving today’s challenges; we’re helping shape the future of EV battery manufacturing. Together, we enable customers to improve output, reduce downtime, and stay ahead in a rapidly changing industry.

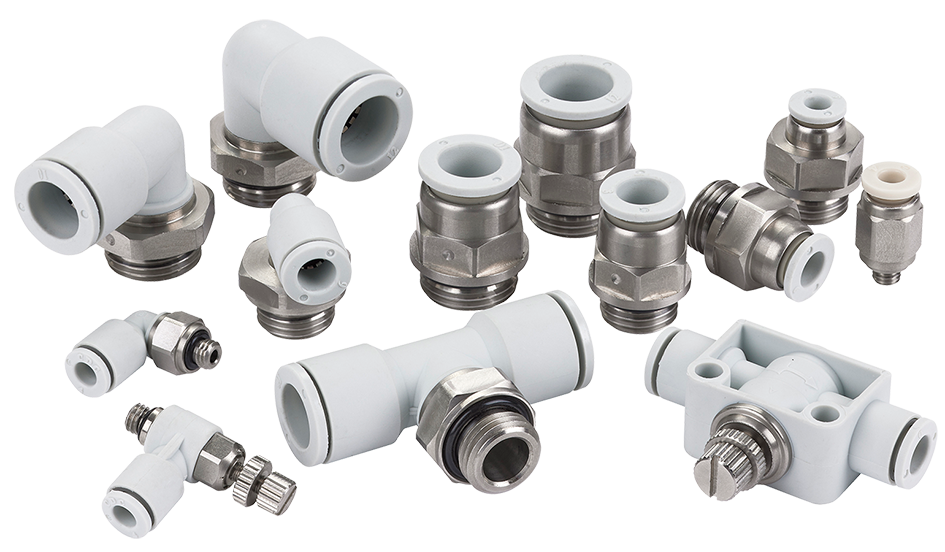

IMI Norgren Pneufit E

IMI Norgren FRL B84G-4GK-QP3-RMG

For more information on Fluid Power, Transfer and Control Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#IMI #ERIKS #LetsMakeIndustryWorkBetter #IMINorgren #EVBattery #Automotive #CleanroomCompliance