In this article

Helping to drive automotive reliability

Working to provide tools that exactly fit your customer’s needs has always been the driving motivation of Piab’s research and development ethos, and their latest offerings to the automotive industry, where assembly speed and safety are first priorities in order to maximise throughout and minimise downtime, are no exception.

A new series of automotive suction cups from Piab addressed the issues of handling oily metal sheets which often also have narrow gripping areas, ensuring that these sheets can be moved securely and efficiently within body shops and parts assembly areas, as well as low and medium speed press lines.

This new line is designed with friction cleats that provide good stability and resistance to horizontal forces during operation, especially where oil is present, as the cups also offer industry standard dimensions and interfaces and can easily be integrated into existing production lines.

Available in round/oval flat, round/long/oval bellow variations, there is a cup suitable for the majority of sheet handling applications and are also a good alternative for applications outside the automotive industry such as wood, metal sheet handling, aerospace, and white goods.

Made from 60 shore (A) silicone-free nitrile-PCV, which creates a durable and cost-effective cup, all the suction cups from the series have a moulded aluminium insert with nine fitting options, including a quick-connect fitting system (T-slot) or can be easily adapted for your own fitting solution.

With a wide cup lip for better sealing over dust and debris, all the cups are designed to operate even at low vacuum levels, resulting in less energy consumption and faster production lines.

Unique Fail-Safe vacuum unit

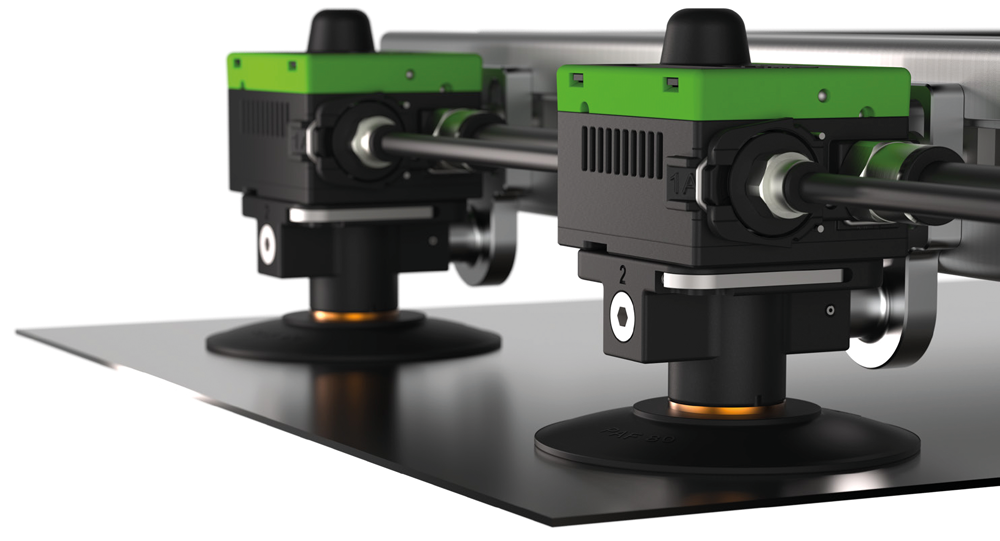

Where it is imperative that valuable metal sheets are held and moved securely, in keeping with production schedules, Piab has developed their piSAFE® program which, in combination with market leading vacuum performance through their patented COAX® technology, is the perfect choice for challenging robotic applications and ergonomic handling devices where safety is a key concern.

Designed with outstanding safety and energy saving features, the products in Piab’s piSAFE® program have been specifically developed to provide configurable and low weight solutions that can be adapted to your needs.

Whether you want a centralized or decentralized vacuum gripping system, interfaces that match common (industrial standard) EOAT systems, or stand-alone mounting, the piSAFE® program provides a high vacuum safety and high performing configuration.

piSAFE® program key benefits include:

- Vacuum safety non-return valve (check valve) which holds vacuum in sealed applications in case of system or power failure

- Can replace more expensive mechanical or vacuum-tank safety arrangements in robotic tools and ergonomic equipment

- Suitable for ergonomic lifting devices/manipulators and cranes which must comply with lifting norms such as (DIN/SS) – EN 13155 and ASME Standard B30.20

- Through the energy saving features, the noise level is reduced as well as the carbon footprint. The air consumption is reduced by up to 98% per cycle

- Light-weight materials lower the weight on EOAT and ensure less wear on robotic motors and drives with possibility for increased speed/acceleration or a smaller, cheaper robot

piSAFE® program key feature:

- Configurable with vacuum ejector based on COAX® technology with integrated control functions for energy-saving and release

- Vacuum sealing port included for easy installation of good-to-go switch

- Configurable with different types of release functions supporting maximum release speed and air-consumption free release

- The modular design facilitates opportunities for easy maintenance, quick connect options and fit for application configurations

For more information on Safety solutions and to get in touch with one of our ERIKS Safety Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Reliability #Automotive #Vacuum #Suction #Safety #Engineering #ERIKS #LetsMakeIndustryWorkBetter