In this article

Valves: The small component driving big change

Few components are as ubiquitous in industrial settings as valves. Yet behind their apparent simplicity lies a complex interplay of cost, safety, sustainability, and innovation. The humble valve is fast becoming a focal point in the tug-of-war between engineering priorities, commercial pressures, and environmental obligations.

In countless facilities across the UK, this silent struggle plays out daily. Engineering teams focus on performance and reliability. Senior leaders push to meet energy and carbon goals.

Meanwhile, procurement prioritises price, lead times, and working capital. The outcome? Sometimes all three succeed. Too often, nobody wins.

Take the example of a routine steam trap survey. On average, 15 to 20% of steam traps are either leaking or not working correctly. One ERIKS customer was found to have 50 failed traps. Each one can waste up to £2000 per year in energy losses. That’s £100,000 evaporating into thin air.

Yet when ERIKS presented a replacement steam traps programme showing a strong payback, procurement rejected it. The invisible cost of energy and carbon loss was deemed preferable to visible capital spend.

Procurement pressure ignores long-term savings

In this scenario, sustainability targets were undermined. The engineering team’s workload increased. And senior managers were left wondering why their site performance plateaued. This isn’t just a technical problem. It’s a mindset problem. Long-term value must start to outweigh short-term budgeting wins.

That’s not to say innovation and collaboration are absent. Positive examples exist in sectors such as food and beverage and in data centre applications. In both, valve performance is directly linked to energy efficiency.

Data centres in particular are innovating fast. HVAC systems demand precise control, and ERIKS supports this through its econ® range and a growing ability to integrate products into 3D Revit designs.

Engineering expertise drives better outcomes

One creative example comes from the Paris Olympics, where heat recovered from a nearby data centre was used to warm the Olympic swimming pool. That kind of joined-up thinking is becoming more common but still needs stronger cross-departmental commitment.

Repair is another trend worth watching. Where once it was normal to replace valves entirely, today more customers are requesting refurbishment. In part this is driven by cost pressures, but there’s also a growing desire to reduce waste.

The challenge is that few facilities have the capability to repair, recalibrate and recertify valves across a wide size range.

That’s why ERIKS invested in its Valve Centre of Expertise in Leicester. Here, customers can access full support for valve repairs from 1.1/2 inch to 14 inch, across ball, gate, globe, control, pressure relief, safety and check types. Function testing, actuator repair, hygienic cleaning and pressure testing from 7 to 1000 bar are all on offer.

Sustainability must be a shared mindset

One growing area of concern is safety compliance. The Pressure Systems Safety Regulations 2004 require regular certification of safety and pressure relief valves. But awareness remains patchy.

ERIKS not only performs repairs and recertification, it also logs every asset, enabling tracking and automated renewal notifications. This reduces risk and protects both people and productivity.

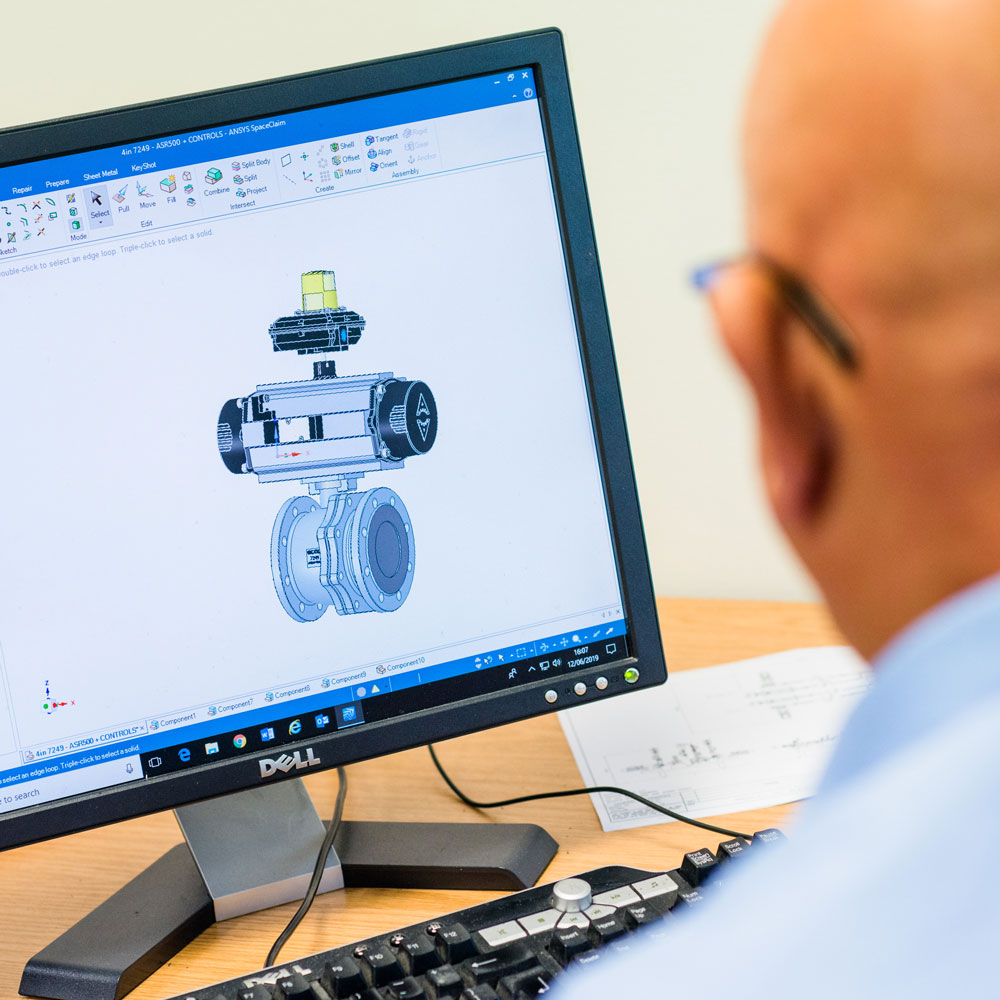

Being an independent valve expert with its own manufacturing capability sets ERIKS apart.

The econ® range includes ball, butterfly and globe valves plus actuators, combining heritage with customisation potential.

For example, when a Certified Sustainable Palm Oil producer needed actuated ball valves for a new tank farm, ERIKS didn’t just supply what was asked. It examined the application in depth.

Because the tanks were located near the sea, standard aluminium actuator enclosures risked corrosion. ERIKS recommended epoxy-coated actuators for improved resistance, extending service life and safeguarding reliability. It was a tailored, engineered solution not driven by price but by performance.

It’s this blend of practical know-how and strategic thinking that defines ERIKS’ approach to valves. Customers don’t just get products. They gain insight, guidance and options aligned to their needs.

Apprentices learning alongside seasoned experts ensure that this capability will remain part of ERIKS’ offer well into the future. Because as valves quietly go about their work behind the scenes, their importance to energy, safety and sustainability is only set to grow.

For more information on Flow Control solutions and to get in touch with one of our experts, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #econ #Valves #ValveCentre #Sustainability #Compliance