In this article

A dose of common sense saves snack-maker a packet

The last thing a food manufacturer wants is something that leaves a nasty taste in the mouth. But if an asset is frequently failing, and the same part needs replacing again and again, it’s bound to make you feel a bit sick. Fortunately, before one manufacturer had to swallow any more costs, ERIKS stepped in with a solution that delivered tasty savings.

Working in an ERIKS OnSite Stores involves more than just finding the right part and handing it over. You also think about the parts you’re supplying, and you consider whether there’s anything you can do to help the customer achieve higher efficiency, greater productivity, lower costs, and safer or more sustainable operations.

So when the OnSite Stores at a food manufacturer’s site was repeatedly handing out the same replacement hose for two identical assets, the Manager knew it was time to ask ‘why’.

Flavour of the week

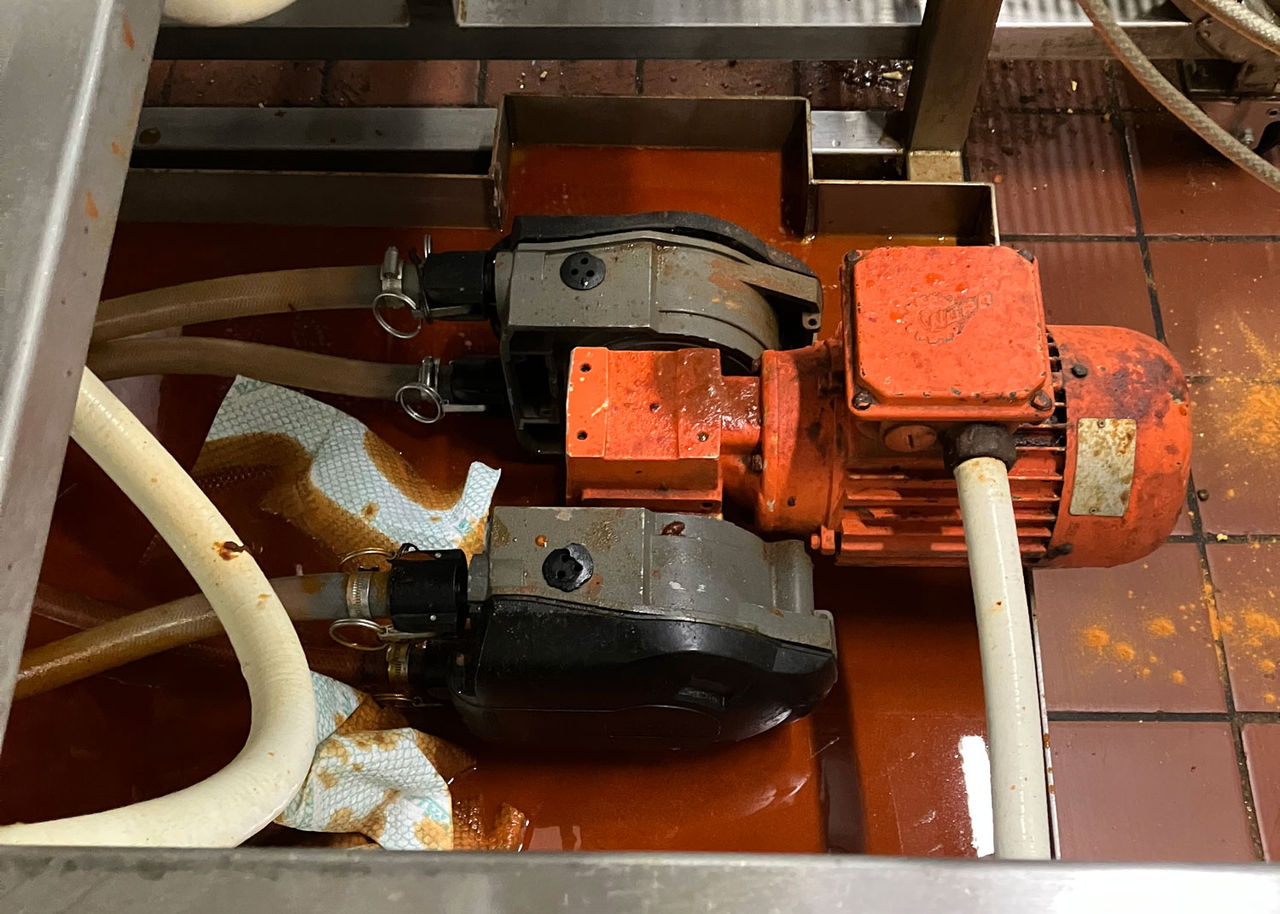

The hose is part of a peristaltic dosing pump, used to add flavour to a snack product. As the snack product rotates in a drum, the pumps add a precise dose of flavouring at a precisely set speed. This ensures the snacks have a consistent taste, bite after bite and packet after packet.

With two of these pumps on site, a new hose was being requested at least once a week. On a 24/7 production line, the pump downtime was having a major impact on output, as well as incurring significant costs for parts and labour.

So instead of simply handing out yet another hose, and letting the customer go on throwing good money after bad, the Stores manager suggested a visit from an ERIKS Application Engineer.

Flavour of the leak

It wasn’t just downtime, labour and parts costs which were an issue for the customer. The failed hose also allowed the expensive liquid flavouring to leak away – creating a potential slip hazard on the factory floor.

However, even without the cost of the wasted flavouring, the repeated pump hose failures were costing the customer £120 a week for parts and £180 per week in labour and downtime.

That’s £31,200 a year in total. And you need to sell a lot of bags of snacks to recoup that kind of money.

Pumping for answers

Naturally the customer had first approached the pump’s original manufacturer for support. But help and advice weren’t forthcoming. So ERIKS offered to arrange a visit from an Application Engineer.

This was not just a brief visit to inspect the pumps. It also involved discussion with the customer’s own engineers, and the involvement of the ProMinent Group - an ERIKS pump supply partner – in consultations.

After ERIKS’ visit to the customer’s site, the customer’s engineers visited a local ProMinent pumps workshop, to assess a proposed new pump solution.

First bite at the snacks

The proposed new pump features a more robust hose, making it less prone to failure. It’s also a more modern design, which allows a faster swap-out of the hose if it needs to be replaced.

Impressed by the proposed solution, the customer initially installed one of the new ProMinent dosing pumps as a trial. This replacement not only proved successful in maintaining the accuracy and consistency of the flavour dosing, but also ran far more reliably than the previous pump.

Satisfied with the trial results, the customer then replaced the second dosing pump with the new model too.

Easier to swallow

The pump hoses which were previously being replaced once a week now require replacement no more than nine times a year.

Running costs have been drastically reduced: to just £180 per pump every six weeks, including replacement parts, labour and downtime. That’s a total of £3,240 a year for the two pumps, or a total saving of £27,960 per annum. So payback for the two new pumps took less than 12 months.

The new pumps are also future-proofed for a change from manual to automatic dosing control, with a variable speed drive and a PLC interface.

In fact, they have everything the customer needs for making snacks without snags.

For more information on Flow Control, contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #CostSavings #Pumps #OnSiteSolutions