In this article

Pumped for information

Just because something is widely used across a range of industries and applications, doesn’t mean it’s being used the right way. Familiarity breeds contempt, sloppy practices creep in, and what should be the most efficient and effective solution can all too easily become a liability. That’s why we pumped ERIKS’ engineers for their know-how on Best Practice for air-operated double diaphragm (AODD) pumps – to help you make the simplest solution the most successful too.

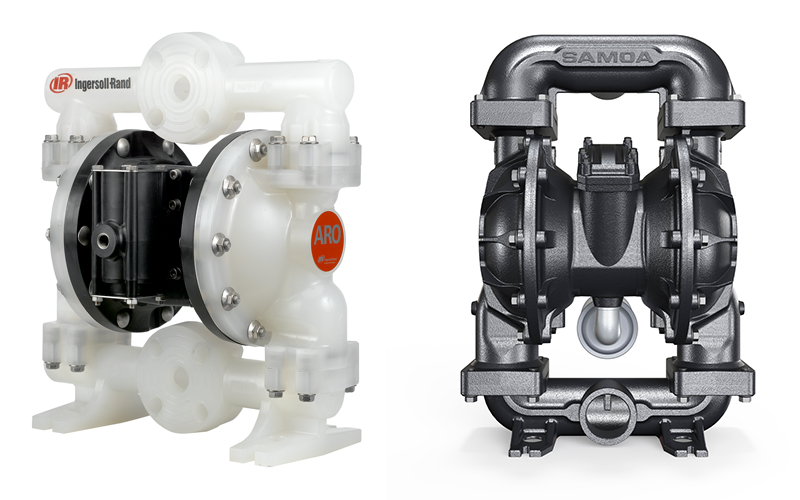

AODD pumps are the most common pump in use across the whole of industrial manufacturing, because of their capabilities and flexibility. You will find them used for liquid transfer applications in industries of all kinds, from chemical manufacturing to printing. And you will see them applied to anything from pumping viscous products to handling foodstuffs.

Their popularity is mainly due to the advantages they have over other types of positive displacement pumps.

Pump plusses

AODD pumps can happily handle aggressive chemicals and abrasive products. They can run dry without damage, and self-prime up to 7 meters. They are generally easier to maintain, and simpler to operate. And it’s not just the pumps themselves which are simple.

It’s their installation too.

Because they are powered by compressed air, there’s no need for electrical cabling or control panels. So there’s no need for an electrical power source. This simplifies installation, and means they can be located in explosive or hazardous environments where electricity would be a safety hazard.

In fact, for almost any difficult application, the simplicity and flexibility of AODD pumps has made them the go-to solution. Yet they do have a significant disadvantage.

Fortunately, Best Practice can help to overcome it.

As free as air?

Producing compressed air can be expensive, and AODD pumps can consume a lot of it.

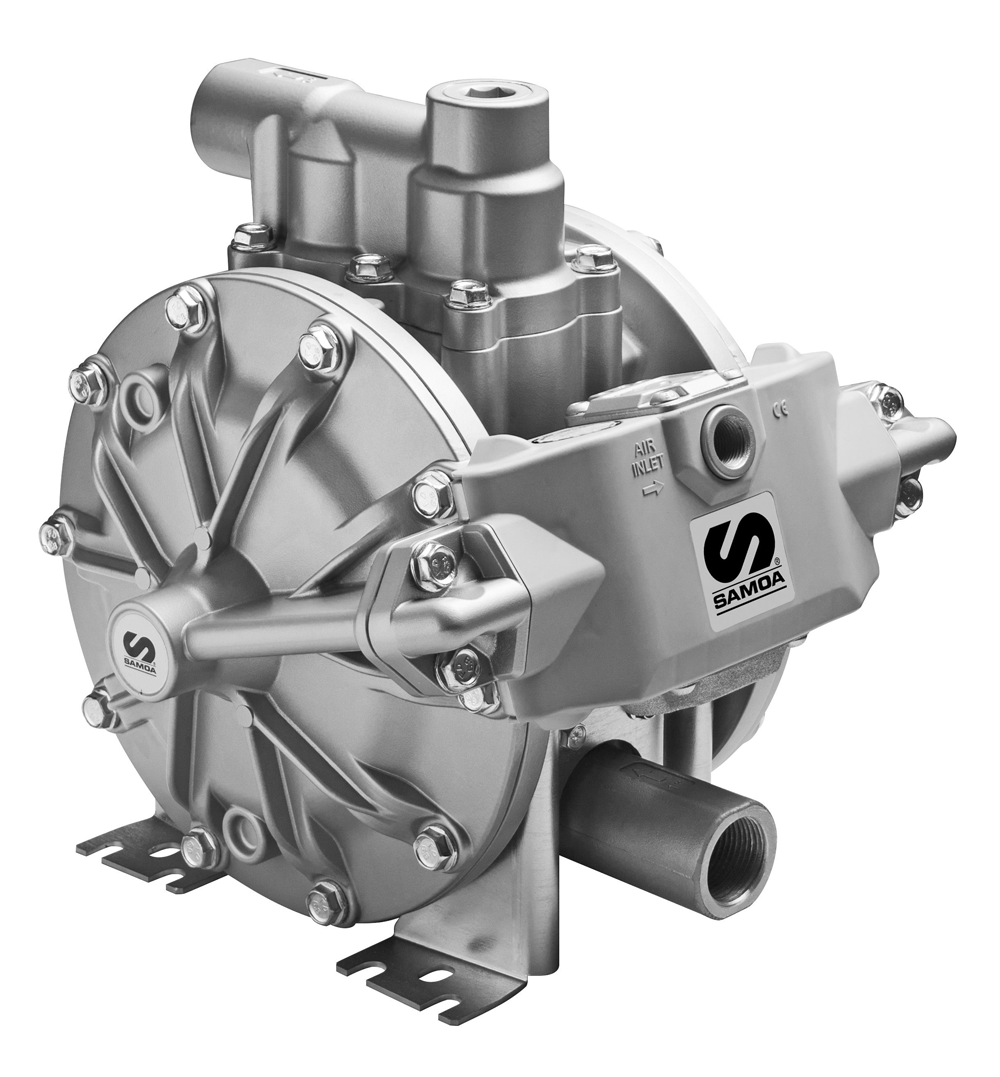

There has been significant progress in reducing the cost of compressed air production, particularly from ERIKS partners Ingersoll Rand, Tapflo and Samoa, who are designing extremely efficient air motors. For example, Tapflo’s Low Energy Air Pump technology (LEAP) is – as the name suggests – a real leap forward in energy-efficiency.

However, selecting the wrong pump, or installing it incorrectly, will still lead to inefficiencies. So it’s important to follow Best Practice in specifying and installing.

Take control

The most common error is to install an AODD pump without a flow control valve or pressure regulator. This will negatively affect running costs and service life.

Firstly, the pump will consume more air than the application requires. So you use, and pay, for energy you don’t need. Secondly, without flow control or pressure regulation, the pump will constantly be running at full flow. This has the effect of shortening the life of the diaphragms, resulting in more downtime and higher service costs. Pumps with PTFE diaphragms are particularly affected.

Clearly a flow control valve and a pressure regulator are essential for efficiency and cost-effectiveness. But what else do you need for a Best Practice AODD pump installation?

Bells, whistles and valves

There are several additional accessories which should be added to any AODD installation to optimise its performance and cost-efficiency:

- To enable control of the pump operating pressure, the air inlet valve should be fitted with an air shut-off valve, a filter, and a regulator with a pressure gauge.

- To control airflow into the pump – which affects the pump running speed – a needle valve should also be fitted. The pump running speed ultimately dictates the flow rate of the fluid being pumped.

- To prevent vibration issues and reduce the risk of compressed air leaks, the pump should be mounted on anti-vibration mounts, and connected into the pipework using flexible bellows. All pipework should also be fully supported.

- For the most efficient priming of the pump, suction lines should be kept as short as possible.

- For easier isolation in case of operating issues, shut-off valves should be fitted to the fluid inlet and outlet.

- A pressure gauge will be a useful diagnostic tool for engineers troubleshooting problems with the pump or the system.

- In addition, pulsation dampeners, diaphragm failure sensors and batch counters can all be fitted if appropriate to the application.

Follow all these best practices, and your AODD pumps will prove why they’re still the most commonly used in industry.

For more information on Flow Control solutions and to get in touch with one of our ERIKS Pumps Specialists or Valve/Flow Control Engineers, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #WaterFlow #Innovation #FlowControl