In this article

Don't throw your money away

What happens when an asset fails? Do you replace it with a new one? If you do, how do you replace the money already invested in the failed asset? How do you remove the carbon already generated by its production? And how do you throw the asset away? Because in reality, there is no ‘away’ to throw it to. There’s only ‘somewhere else’ – which usually means into landfill. Fortunately for your budget, your carbon footprint and the sustainability of your operations, there is another option. Repairing a failed asset and re-using as many of its components as possible, can be the most economic, energy-efficient and sustainable step to take.

The need to make industry more sustainable is leading many businesses to start going round in circles. Not because they don’t know where they’re going, but because they have joined the circular economy through repair, re-use and recycle.

This is a circular route which puts their assets such as motors, pumps and gearboxes on a straight road to longer service life, greater energy-efficiency, a smaller carbon footprint, and a lower total cost of ownership (TCO).

But even when you know what to repair, the question is: who’s going to repair it?

Know everything or know-all?

The obvious choice of repairer may be the OEM. After all, they know everything there is to know about their asset. What they don’t know is the bigger picture.

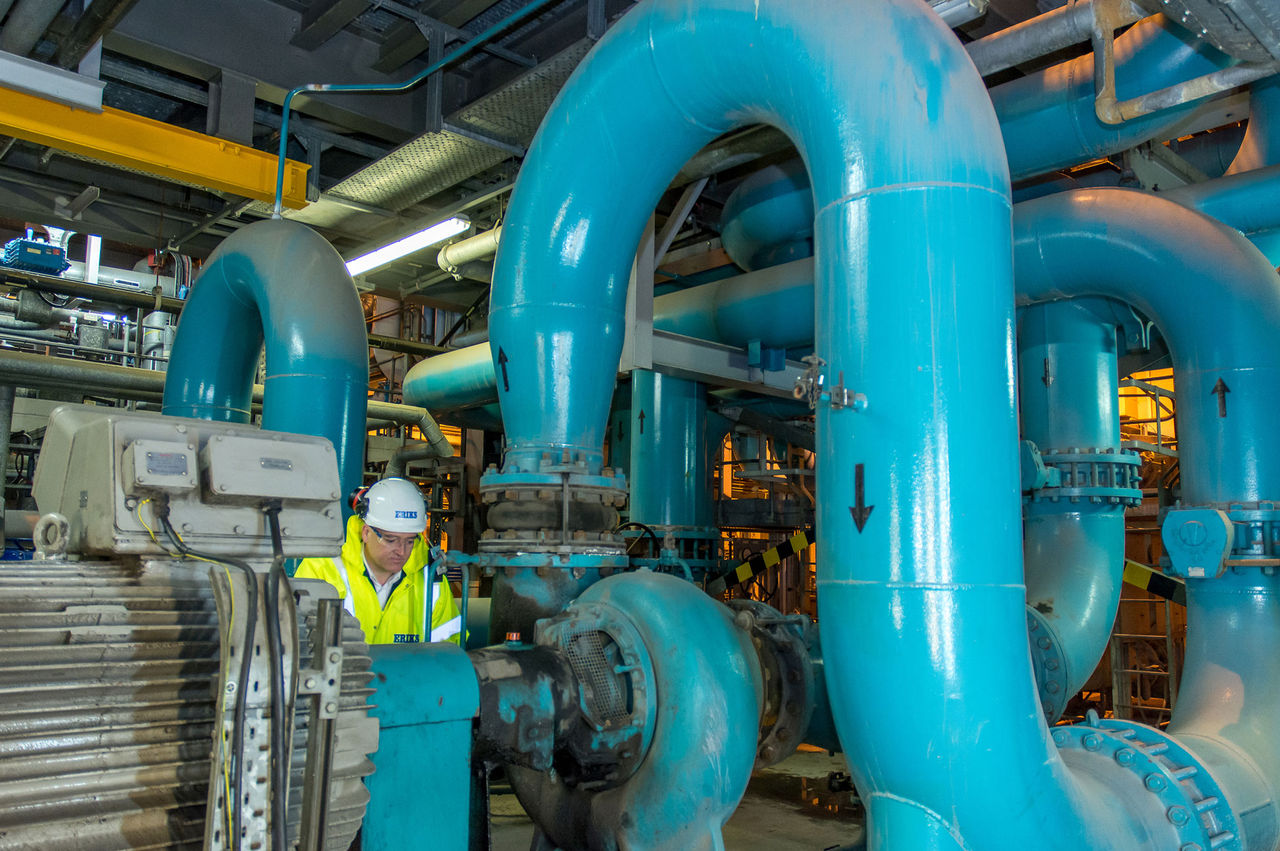

ERIKS Repair Service engineers know all about the assets – motor, pump or gearbox – based on years of experience of installing, maintaining and repairing them. But they also know about every application across a broad spectrum of industries. About every potential failure mode. About the most likely issues, and the least likely too.

And therefore they know all about every aspect of repair – from the quick fix to the workaround to get you up and running quickly to the long-term reliable solution. As well as how to overhaul, how to restore to Original Equipment standard, and even how to upgrade to optimise efficiency and maximise service life.

Only change stays the same

Your asset may have been perfect for the job when it was first specified and installed. But things change.

A pump may originally have been the correct size for its duty, but what if the system has changed around it? It may be still be doing its job, but is it doing it with optimum performance at the best possible point on its efficiency curve?

Has technology improved enough to offer a more efficient solution to do the same job?

For example, an ERIKS customer was using 30+ year-old pumps to deliver high-pressure water to jet nozzles. But improved nozzle technology now makes it possible to lower the flow rate and still achieve the same pressure at the nozzle. Which means less energy is required to pump the water, and less water is used overall. That’s a win for the energy bills, a win for the environment, and – by upgrading rather than replacing the asset – a win for sustainability.

Plus, it was a prime example of ERIKS’ wider industry knowledge enabling the engineers to see the solution didn’t lie just in the pump, but in the bigger picture.

Prepare to repair

A repair is almost always a more sustainable solution than a replacement. And with ERIKS online monitoring, you can make repairs more sustainable still.

By monitoring vibration, temperature, power, speed and – for pumps – the head and flow rate, you can build up a clear picture of your assets’ performance, and the performance trends over time. Which means that rather than being caught out by a sudden failure, you can identify when a repair or upgrade is likely to be needed, and plan ahead to carry it out at a convenient time in a controlled manner.

Instead of a costly ‘break/fix’ way of working, you can adopt a ‘monitor/repair’ mindset. And that’s not only more sustainable, but also more cost-efficient.

To find out more about monitoring, maintaining and repairing your assets for maximum sustainability, talk to your local ERIKS representative about ERIKS Repair Services. Why stay left outside the circular economy? It’s time to join the inner circle.

For more information on Engineering solutions and to get in touch with one of our Engineering Specialists please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #RepairOrReplace #Sustainability #Motor #Pump #Gearbox