In this article

Reactive. Preventative. Predictive. Proactive. Which are you?

How do you deal with the risk of a heart attack? Hope there's an ambulance nearby? Or eat fewer chips and join the gym? What about your car? Do you keep the wipers in good condition and check they're working? Or do you just hope it doesn't rain? Most people make the sensible choice about their health and their car. But when it comes to their rotating equipment, some are dangerous risk takers.

Lack of investment throughout UK industry has left almost three quarters of factories using equipment that is over 10 years old. At the same time, maintenance teams who keep it running along have shrunk by 64%. And even if companies do invest in new machinery, its increasing complexity often uses new technologies that require additional training and skills, stretching maintenance teams further.

This combination of factors can lead to asset failure, breakdown, and unscheduled downtime. Which can lead to more than just loss of production.

A leading performance improvement company survey identifed the common characteristics of worst-performing companies. They were those spending four times more on maintenance than the best-performing, but still suffering 15% more downtime.

But it's not only the business that's at risk. Further research in 2018 by Reliable Manufacturing revealed that during breakdowns, those maintenance teams are nine times more likely to have an accident than when they're undertaking scheduled maintenance.

The problems are worrying. But there are solutions for your rotating equipment that are just as easy, and just as effective, as changing your wiper blades. Which one is right for your particular motors and gearboxes depends on how far you've already gone on your maintenance journey.

A vicious circle

The working life of an electric motor should be 15 years. If you find that hard to believe based on your own experience, you won't be the only one. Because 80% of motors never achieve it.

Reasons for shorter service life vary: from poor maintenance (51%) , to overloading (21%), incorrect specification (16%), and poor installation and alignment (12%).

The results however are always the same. Frequent breakdowns, unscheduled maintenance, increased downtime and loss of uptime.

When budgets and maintenance teams shrink, run-to-fail can quickly become a policy by default. What completes the vicious cycle is a reliance on reactive maintenance at the lowest possible cost.

The two scenarios at the bottom, based on real-time customer experience, demonstrate the problem and the solution one ERIKS customer has adopted.

React, Prevent, Predict

Taking advantage of ERIKS' facilities, capabilities and know-how is the first step towards minimising your downtime and optimising the efficiency and cost-effectiveness of your rotating equipment. But essentially, you've only chosen a better ambulance service. Prevention is a more effective step still.

Whilst ERIKS' engineering expertise helps resolve the root cause of failures during the repair process and identifies efficiency opportunities, which can move you towards preventing repeating asset failures.

These efficiencies don't have to be major investments to deliver sizeable returns. For example, an ERIKS customer's maintenance engineers were manually greasing all rotating equipment. There was no greasing schedule. Different engineers applied different amounts. And accessing the grease points involved climbing over safety fencing, exposing personnel to risk of injury.

ERIKS costed the installation of automatic greasers, calculated the savings on engineers' time, and helped the Production Manager present a strong business case for the investment. Now the assets are greased at the optimum level - a valuable preventative measure - and the engineers use their time more effectively to increase reliability and uptime.

They're now free to work towards the next step: moving from prevention to prediction.

Foresight and insight

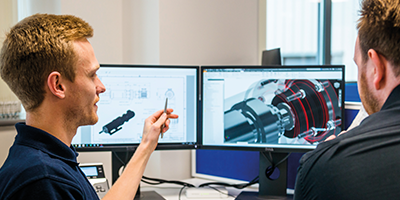

Predictive maintenance let's you work smarter. Using condition-based monitoring gives you the advanced warning (foresight) and what the potential issue is (insight) so that you can create a tailored maintenance schedule, and take real control of how your assets are looked after.

If you carry our maintenance to the manufacturer's schedule, you could be replacing components too often, or too late. But tailor your maintenance to your specific operating conditions, working environment, and knowledge of probable failure modes, and you can optimise your planned maintenance schedule, minimise downtime, increase efficiency and reduce Total Cost of Ownership.

However, you should choose your Condition Monitoring service carefully. Some simply present you with a list of problems they've identified. ERIKS can take ownership of the issues identified working with you to implement approved cost saving solutions.

Engineering your downtime away

As your need for reactive maintenance decreases, and you adapt a balanced mix of preventative and predictive maintenance measures, you - and your budget holders - will start to notice the difference.

There'll be less unscheduled downtime. Maintenance costs will fall because you're not paying a premium for emergency responses for critical failures. You'll even start to see some incremental benefits as your engineers spend time identifying and implementing efficiency improvements.

Now you can take the final step on your maintenance journey, and start to think proactively.

Technical know-how - in-house or from experts like ERIKS - can help you to engineer-in reliability and operational efficiency. ERIKS can help you to establish an asset database and identify critical parts. (Almost half of factories are unaware of the lead time on spares for critical equipment. Over 70% hold no spares. ERIKS holds £22 million of stock for next-day delivery).

Ultimately, you'll see motor and gearbox failures not as an inevitable part of your operations, but as something you can anticipate - and minimise.

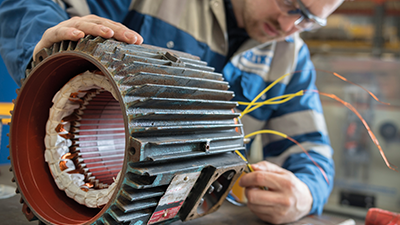

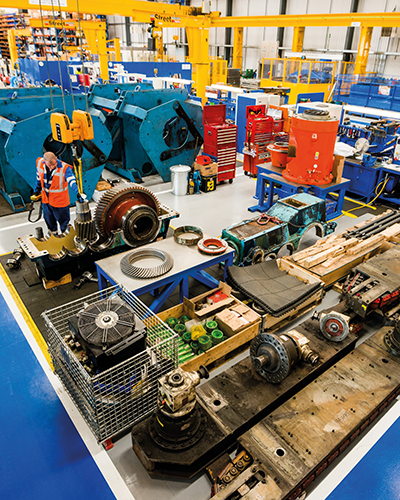

ERIKS Specialist Repair Facility

When oil leaks from a gearbox, the customer contacts ERIKS. The asset is collected and taken to one of 19 specialist repair locations nationwide. Working to documented repair processes and industry best practice, ERIKS' highly-skilled engineers dismantle the gearbox for inspection and identification of the root cause. All bearings and seals are automatically replaced.

The repair is audited, and all parts used are fully traceable. The gearbox is reassembled, tested, and returned in good-as-new condition, guaranteed.

MTBF is greatly extended, TCO reduced, and efficiency and productivity increased.

The ERIKS team will also evaluate the cost/benefit of a replacement or upgrade depending on your circumstances, they'll provide costings for repair and replacement/upgrade options, so you can make an informed decision which could save repeat failures and repair costs in the long-run.

For more information on Engineering, Repair and Replace solutions please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Engineering #Maintenance #OnlineMonitoring