In this article

Why operational excellence depends on asset reliability - and how to ensure both

It doesn’t matter which industry sector you operate in, or what processes make up your production operations. Whatever you manufacture or produce, you will have critical assets within your facility which represent a disproportionate risk to your productivity should they break down.

If these assets are unreliable, they will increase maintenance costs, create operational bottlenecks, reduce efficiency and potentially even compromise safety. (A catastrophic failure of rotating equipment, for example, can turn rotating components into lethal missiles.) On the plus side, simply by ensuring that these critical assets reliably continue to perform efficiently, you can minimise downtime, reduce costs, increase safety and maximise productivity.

But who do you rely on to optimise asset reliability – and how do they do it?

Knowledge is power

The more you know and understand about your critical assets, the more effectively you can ensure that they continue to operate at their most efficient and productive, with minimum downtime and maximum uptime.

And if you are able to access this information in real time, then your ability to minimise unforeseen breakdowns, to lower the costs of maintenance and energy, and to reduce operational expenditure, will be significantly improved.

It may not be possible to eliminate every breakdown. But it will be possible to avoid catastrophic failures and the major impacts they have on efficiency, productivity and profitability.

Safety will be improved not only through a reduced likelihood of dangerous equipment failure, but also through the application of planned, proactive maintenance. (Statistics show that unplanned maintenance resulting from breakdowns is more likely to lead to injuries.)

You will be able to eradicate undiagnosed or misdiagnosed reliability issues. And with real-time and historic data at your fingertips, you will even be able to make better informed operational plans for the future.

So how do you go about accessing, collating and interpreting the crucial data from your critical assets?

Sensors make sense

From bearings to fans, gearboxes to pumps, and inverters to valves, changes in vibration, temperature, fluids and performance are key indicators of potential issues with assets.

By carefully positioning sensors where they can collect this data, and monitoring the results to identify changes and anomalies, it is possible to obtain very accurate early warnings of issues which could lead to breakdowns. This then enables early intervention through maintenance, to rectify the problem and prevent it from developing further.

Manufacturers such as SKF and Schaeffler offer basic sensing and monitoring solutions of the shelf. The sensors provide entry-level data gathering suitable for simple systems, and for assets where access is difficult.

The proprietary solutions generally include a limited range of sensors to choose from, and a software app for anomaly detection based on data collected every one to four hours. SKF’s’ out-of-the-box Axios monitoring product is a great example of these self-installed monitoring solutions.

One of the main requirements to ensure useful results from the sensors is to identify the best combination of sensors and location.

This needs to be where they can gather the most relevant and informative data. As such, it demands knowledge of how and why vibrations, temperatures or fluids can change their values – and where those changes can be most readily and most accurately detected.

Then, once the relevant data has been collected, its value depends on the ability of the asset’s operator to analyse it correctly, and to act in a timely and appropriate manner to pre-empt breakdown or catastrophic failure.

Alternatively, a fully integrated product relieves the asset operator of the burden of correct installation, data collation and interpretation, and – depending on the chosen level of support – even of taking action.

The ERIKS Smart Asset Management (SAM) Reliability Platform, for example, supports these two levels of service offering powered by analysis which delivers insights, to interpretation which informs – and triggers actionable solutions. It’s down to you whether you install the sensors yourself or rely on ERIKS expertise, let me explain.

Empowering optimised performance

More than 100 market-leading companies across a wide variety of industry sectors already benefit from early warnings via the ERIKS SAM Reliability Platform.

In industries ranging from food and beverage to steel, from packaging to pharmaceuticals, and from healthcare and construction to chemicals, this real-time cloud-based monitoring platform is helping to support engineering teams in mean time between failure, minimising downtime and maximising productivity.

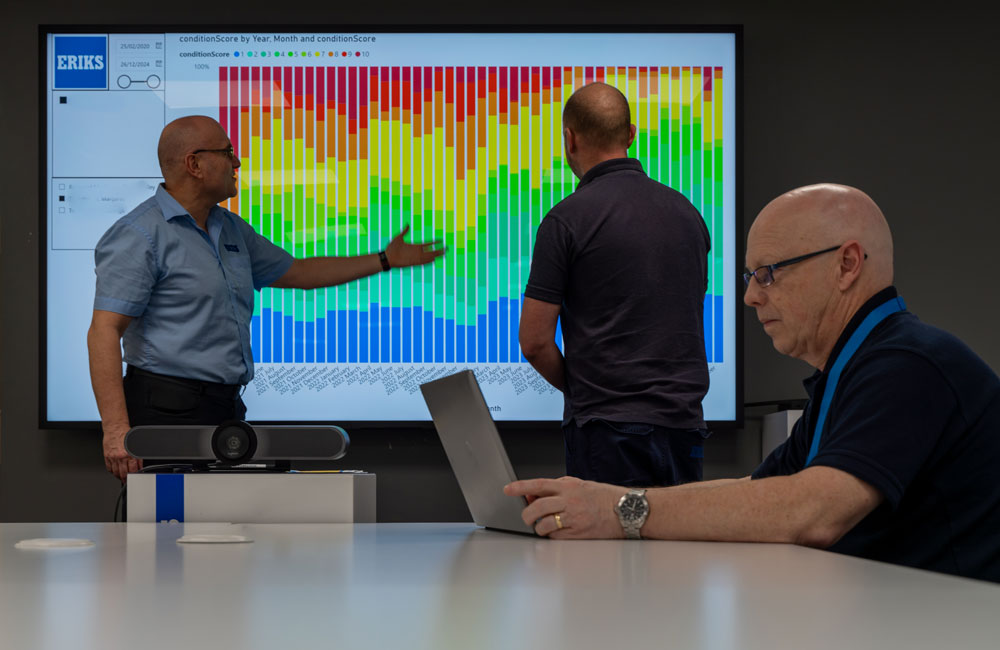

In addition to algorithmic data analysis, the Reliability Platform offers live status monitoring. Condition scores from 1 to 10, with green/amber/red colour coding, make it easy to understand asset health at a glance. Smart maintenance alerts enable proactive maintenance. Smart algorithms will even provide diagnosis of potential causes, and propose actionable solutions.

And a digital central repository of the history of the asset and its certification helps to streamline documentation.

Reliability at every level

Two levels of protection are available with the Reliability Platform:

Advanced Service Level Protection

- Collects real-time data from a sensor network. This data is then analysed by the ERIKS dashboard, to provide deep insights into machine health. The data is presented in a user-friendly, informative way, to enable users to take timely actions and implement early preventative measures.

- With a minimum of 20 sensors, supplied by ERIKS and installed by the customer, the Advanced Service Level collects data from as frequently as 5 or 10 minutes, can be accessed 24/7 and informs you of any issues.

Professional Service Level Protection

- Provides real-time monitoring driven by a network of sensors designed and installed by ERIKS, providing predictive maintenance alerts and actionable insights.

- The unique cloud-based asset management platform is monitored by a dedicated support team of expert technicians, who swiftly identifying issues to implement fixes turning amber warnings into green lights for your production.

- Packages start with a minimum of 20 sensors that are installed and commissioned by ERIKS engineers, to collect data as frequently as every two minutes.

Reliably evolving

As industry’s needs change, so should condition monitoring. That’s why ERIKS SAM Reliability Platform is continually evolving and improving.

It’s not just a network of sensors. It’s not only a data gathering application. It’s even more than a remote condition monitoring system.

ERIKS SAM Reliability Platform is a complete, integrated, reliability package. It provides you with deep and invaluable insights into your equipment. It is supported by experts in reliability, who can act on those insights to ensure your assets operate at their optimum efficiency, with lower maintenance costs, minimum downtime and maximum productivity.

It is the key to reliably unlocking operational excellence through informed, intelligent maintenance of your most critical equipment.

To discover how the ERIKS SAM Reliability Platform helped one customer monitor the unmonitorable, read the blog: ‘Why online monitoring has a new fan’.

For more information on Smart Asset Management, contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Engineering #ConditionMonitoring #Reliability #SmartAssetManagement