In this article

Want to hear a secret? Sealed bearings from SKF extend conveyor lifecycles

Aggressive industries such as quarrying and mining are highly demanding. The rigorous nature of the processes. The ever-changing environment. The unpredictability. The combination of these factors makes achieving efficiency difficult, particularly when you take into consideration elements such as contamination which is unavoidable.

But what if we let you into a little secret? Choosing the correct type of sealed bearings will help extend the lifespan of critical machinery such as your conveyors.

Conveyors are among some of the most critical applications in the mining and quarrying industry, used to move extracted minerals to the next phase of the process. But in order to achieve maximum productivity, your machinery must operate efficiently and reliably.

However, these extreme conditions pose multiple issues. Take excessive dust particles for example, these will cause inevitable premature failure modes in bearings when they progress into the bearing enclosure, leading to expensive and time-consuming maintenance.

Here’s where SKF’s comprehensive selection of sealed bearings come to the rescue, helping to resist ingress and keep your assets running smoothly.

More barriers, more protection, better performance

Typically, the machinery used in quarrying adopts open bearings, which are located in a grease-filled, sealed housing, providing only two barriers to ingress. However, using this technology still requires the bearings cavity to be periodically purged of contaminants – a task that requires excessive amounts of grease.

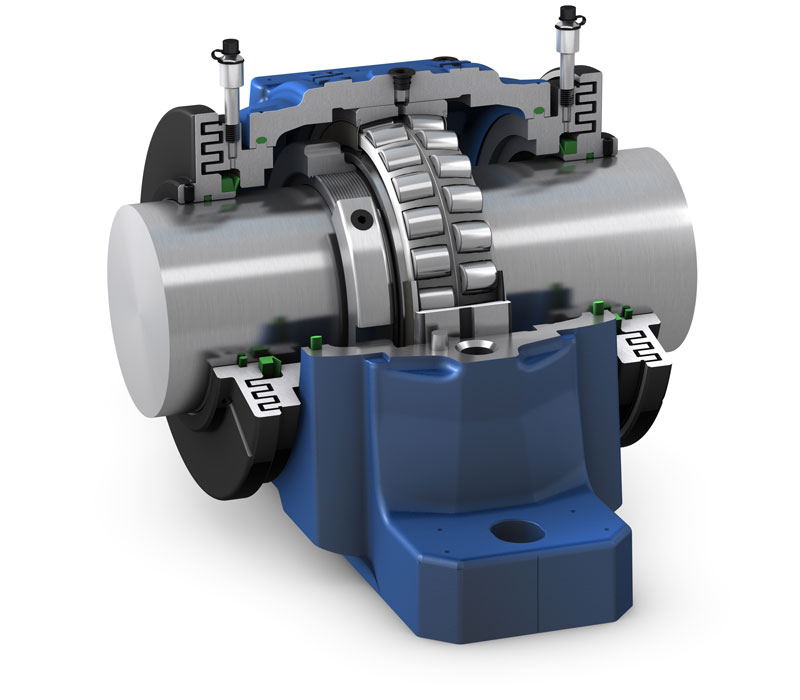

SKF has developed an alternative approach, which adds an additional barrier of protection and avoids purging completely. The ready-to-mount Three-Barrier Solution replaces the troublesome open bearing with a SKF Explorer sealed spherical roller bearing (SRB), which separates the barrier grease from the bearing grease.

The units are factory-filled with the extract amount of lubricant required and are protected by integrated double-lipped nitrile rubber seals on either side of the bearing. Building in such features as standard extends the life of bearings and keeps the need for maintenance to a very minimum.

The bearings themselves are to Upgraded SKF Explorer performance class. Building on improvements in bearing geometry, materials and manufacturing methods seen in Explorer, the upgraded variant features a combination of higher-quality steel and an improved heat treatment process. Upgraded SKF Explorer spherical roller bearings offer further improved performance under poorly lubricated or contaminated conditions.

Reduced maintenance, increased safety with split spherical roller bearings

Conveyors are widely known, in the quarrying industry, as the most difficult to maintain, with the most common problem lying in excessive grease consumption. Generally, conveying systems use standard open-pulley bearings that require large amounts volumes of grease to purge contamination. But open-pulley bearings have a relatively short service life and don’t last as long as the pulley lagging itself.

With short service life comes frequent repair and replacement. Increasing costs even further. Not only are costs driven up, but health and safety risks are increased, as often, these bearing types are inaccessible. They must be hoisted into position during replacement, which increases danger levels for those involved.

SKF Cooper Split spherical roller bearings have been designed to solve this issue.

Replacement is quick and easy, reducing maintenance costs, risks and downtime. The sealed variant resists contamination and greatly reduces the need for lubrication.

More recently, the SKF Cooper SNQ pedestal, or plummer block as commonly known, has been introduced for further convenience.

Designed with an angled silhouette to simplify the fitting of the bearing units, the angled joint allows the pedestal to be slid under the shaft without tools or a hoist to lift the shaft. The design builds on the concept of quick, easy and safe assembly, and removes barriers to conversion. The combination of identical base-to-centre heights, distance between bolt holes, and angled pedestal simplifies the process of changing the arrangement.

Quick and easy shaft mounting with insert bearings

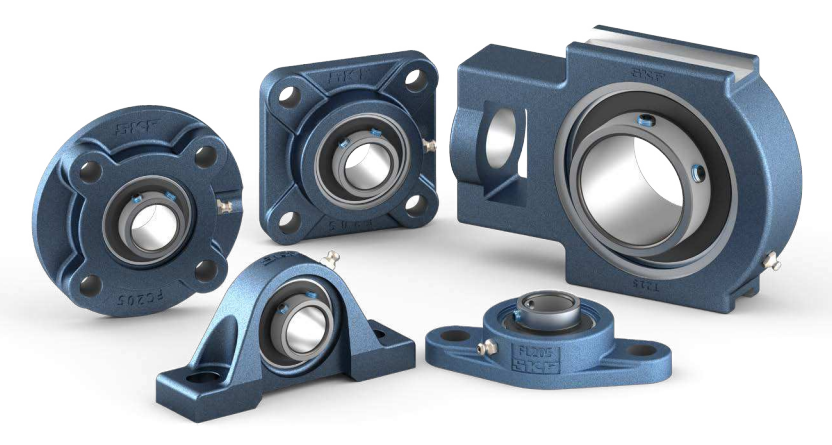

Quick and easy shaft mounting is a feature of SKF’s Insert Bearings, previously known as Y-bearings. Based on 62 and 63 series deep groove ball bearings, they come equipped with an extended inner ring with specific locking device and feature a convex outer ring.

Supplied capped on both sides and greased, Insert Bearings do not require lubrication, even if the grease life exceeds the rating life of the bearing. However, if relubrication is required, the job is further simplified with the inclusion of purpose-designed lubrication holes.

These bearings can also accommodate initial alignment, caused by the housing tilting, while resisting contamination ingress, maximising service life.

Pioneering sealing system

SKF’s UC Range of ball bearings offer optimised protection against contamination, and washdown processes, and are highly recommended for conveyors.

The pioneering sealing system comprises an integral single-lip inner seal, plus external deflector, which is fitted to the inner ring for enhanced sealing. They are also designed with a 120° grub screw angle locking system for applications that require precise shaft balance at high speeds or environments where their exposed to systematic vibration.

Built with a solid base and feet, the smooth design further reduces the possibility of contamination build-up, which is particularly important on a conveying line. Vibration resistance is also improved thanks to the solid base and feet, while the chance of dirt collecting underneath the housing support significantly reduced.

Available with flanged and take-up housings to comply with ever-changing health and safety regulations, UC bearings can be supplied with hydrophobic polypropylene end covers as additional extras.

It goes without saying that aggressive environments of any kind, in this case mining and quarrying, shorten asset lifecycles, with contamination even further increasing the risk. In their mission to be the leader in bearing solutions, SKF’s sealed bearings have a track record for reducing risk, reducing maintenance and increasing service life of applications across a wide variety of industries.

For more information on Bearing & Lubrication solutions and to get in touch with one of our ERIKS Bearings Specialists or Lubrication Engineers, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SKF #Cooper #Bearings #IncreasedSafety #ReducedMaintenance #ThreeBarrierSolution #UCInsertBearings #SealedExplorerBearings #Conveyors #Building #Mining #Quarryiing#ERIKS #LetsMakeIndustryWorkBetter