In this article

Ensuring Cleanroom Success: The role of Ventilation and Air Handling Equipment

Ventilation might not always steal the spotlight, but in cleanroom environments, it plays a leading role. It’s essential not just for keeping the air clean, but also for regulating temperature and humidity, and preventing contamination that could compromise product integrity or safety.

Cleanrooms are crucial in industries like pharmaceuticals, biotechnology, electronics, aerospace, and food production – sectors where even microscopic particles can have serious consequences.

In these tightly controlled environments, Heating, Ventilation, and Air Conditioning (HVAC) systems aren’t just about comfort – they’re vital to success.

A well-designed, efficient HVAC system helps cleanrooms maintain strict environmental control, meet regulatory standards, and support sustainability goals. In short, it’s a smart investment in performance, quality, and long-term reliability.

The Hidden Risks of Poor Ventilation

Poor ventilation in a cleanroom can cause major problems. From increased contamination and inconsistent humidity to reduced air quality and energy inefficiency, the impact can be far-reaching.

In pharmaceutical manufacturing, airborne particles could result in batch contamination, product recalls, or regulatory action. In electronics, a speck of dust could damage sensitive components, leading to failures or costly rework.

Poor airflow can also make cleanrooms uncomfortable for employees, affecting morale and productivity.

That’s why effective ventilation and filtration aren’t optional – they’re essential to maintaining a controlled, efficient environment.

Air Handling Under Pressure

Air handling units (AHUs) in cleanrooms face tough conditions. They must perform reliably despite exposure to heat, dust, corrosive vapours, and frequent washdowns. This constant stress can accelerate wear and tear.

To make matters more challenging, AHUs are often installed in awkward locations like ceilings, rooftops, or cramped mechanical spaces.

These areas are hard to access and can be dangerous for maintenance teams. That makes it critical to use components that are durable, easy to maintain, and built to perform under pressure.

What Bearings Need to Deliver

Bearings used in air handling systems must meet specific demands to ensure cleanroom operations run smoothly:

- Easy installation and removal – To speed up maintenance

- Long-lasting, low-maintenance – For fewer breakdowns and lower costs

- Tolerant of misalignment – For flexibility during installation

- Low friction – To reduce energy use, noise, and heat

- Sealed against contaminants – To protect against dust and moisture

- Temperature-resistant – To perform in all conditions

- Cost-effective – To make scaling across facilities realistic

Why Bearings Fail – And How to Prevent It

Even the best components can fail if they’re not installed or maintained properly. The most common issues include:

- Lack of lubrication – Causing friction and damage

- Contamination – Allowing moisture or debris to degrade surfaces

- Shaft misalignment – Leading to uneven load and premature wear

- Vibration – Damaging bearings and surrounding parts

The solution? High-quality bearings, expert installation, and a proactive maintenance plan.

Solving the Vibration Challenge

Excess vibration is one of the most common – and costly – issues in AHUs. It’s often caused by incorrect installation or poor shaft grip. This is especially true in split housing applications, where even slight misalignment can lead to failure.

If bearings aren’t mounted precisely, it can result in seal damage, premature wear, and unscheduled downtime. That’s why investing in the right training, tools, and components pays off in the long run.

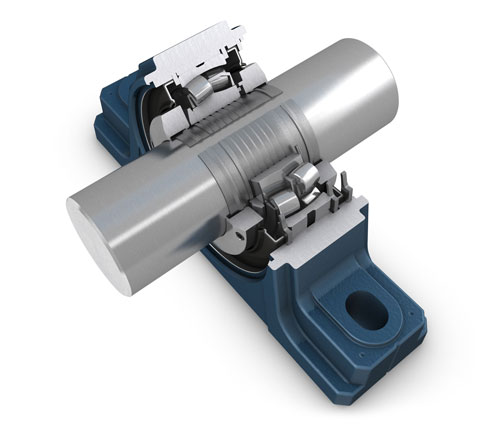

SKF Bearing Solutions for Fans and Blowers

At SKF, we work closely with ERIKS to deliver bearing solutions built for demanding cleanroom applications. One key product is the SKF ConCentra Ball Bearing Unit, designed specifically for fan and blower systems.

These bearings are:

- Durable and reliable

- Ready to mount, prelubricated, and sealed

- Easy to lock onto the shaft

- Engineered for true concentric grip

- Cost-efficient and high-performing

They simplify installation, ensure accurate fit, and reduce the risk of premature failure. In addition, SKF offers seals, lubrication systems, and alignment tools that further protect your equipment. Their condition monitoring services help spot early signs of wear – so you can fix issues before they become costly breakdowns.

Boosting Productivity, Safety and Cleanroom Compliance

SKF’s fan and blower solutions help extend Mean Time Between Failures (MTBF), reduce maintenance and repair costs, and improve overall system reliability. In cleanroom environments, that translates to better compliance, improved safety, and a more productive operation.

Whether you need a like-for-like replacement or a complete system upgrade, ERIKS and SKF have the expertise and solutions to keep your air handling systems performing at their best – day in, day out.

For more information on Bearing Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SKF #ERIKS #LetsMakeIndustryWorkBetter #AirHandlingUnits #Ventilation #CleanroomCompliance