In this article

Bearings for the Food & Beverage sector

At NSK we like to say that our products are found wherever something is moving. This includes everywhere from quarries and mines to wind turbines, automotive plants to some of the world’s most famous subway systems, but it also includes environments where cleanliness and hygiene are an absolute necessity, including the food and beverage sector.

Companies involved in the production of the things we consume know that they must eliminate any and all opportunities for contamination. This means they have to take a component-level approach to production and ensure that their bearings contribute to keeping things clean, without any trade offs when it comes to reliability or productivity.

NSK has many years of experience supplying essential components to this sector, and we’ve used the expertise we’ve built up to develop products tailor made to tackle the challenges presented by food and beverage production.

In simplest terms, our parts are proven to provide continuous, high-speed operation, whilst meeting the most stringent hygiene standards in the most demanding of operating conditions.

They are reliable, robust and enable cost-effective production and maintenance-free operation in high temperatures, in wet environments and when confronted with harsh and intrusive chemicals. Most importantly for this article, they also prevent contamination safely and reliably.

Silver Lube

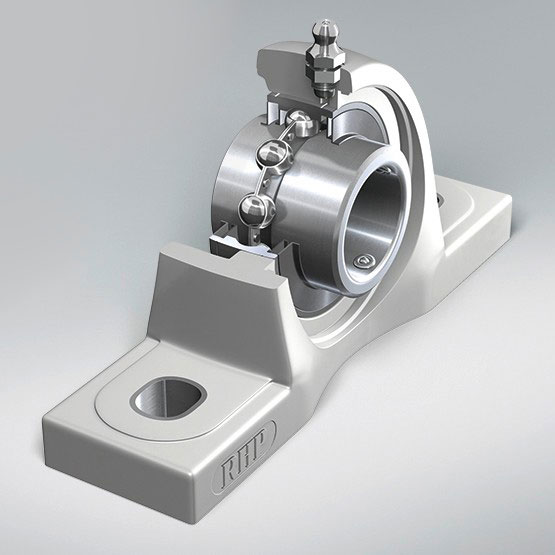

One of our core products for this sector is the RHP branded Silver-Lube range of corrosion-resistant bearing units. Silver-Lube units are made up of bearings inserts with stainless steel components. These are housed within a high-strength, paint free, PBT thermoplastic housing featuring a stainless steel grease nipple and bolt-hole liners, purposely moulded into the housing to make the unit as hygienic as possible.

Silver-Lube units are designed specifically for applications with extremely high hygiene standards, where frequent washdowns are expected, and where good chemical resistance over a range of temperatures is essential to production.

Available in a variety of different configurations (including pillow block, two-bolt flange, four-bolt flange and take-up) Silver-Lube units are capable of accommodating initial misalignment from mounting errors.

This ability, alongside their other attributes, means they are perfectly suited to machines such as shakers, centrifugal separators, bottling machines and conveyors, all mainstays of the beverage industry.

The units also benefit from NSK’s Molded-Oil technology. Molded-Oil is a solid lubricant which prevents the ingress of contaminants including water and particulates, but also prevents the lubricant from escaping the bearing and entering other areas of the machine, where it could potentially come into contact with foodstuffs.

Stainless steel Deep Groove Ball Bearings

Something else we offer is our range of stainless steel Deep Groove Ball Bearings. Made from NSK stainless steel material ES1 which provides better corrosion resistance than standard stainless steel SUS440C in high-humidity environments, our Deep Groove Ball Bearings also feature advanced grease technology, super-finished raceways, patented seals and high-grade balls.

Alongside their quality and reliability, their corrosion resistance is another attribute which makes them particularly well suited to the food and beverage sector.

Corrosion from component parts can harbour bacteria, with obvious implications for environments where food is being prepared.

Like the Silver-Lube range, our Deep Groove Ball Bearings are also available with Molded- Oil lubricant. This set up has further hygiene benefits as it allows for more frequent and intense cleaning sessions. Ordinarily grease can be washed out of bearings if cleaning occurs too frequently, but the solid lubricant found in Molded Oil products prevents this.

Life Lube

Finally, one more option in our arsenal is Life-Lube, a cousin to Silver-Lube and fellow member of our RHP range of products. The Life-Lube series combines the corrosion resistant properties of Silver-Lube housings with the excellent sealing and lubricating properties of Molded-Oil inserts.

Life-Lube units have been developed for use in industries where contact with water and process fluids is unavoidable, excellent chemical resistance is required, and a longer lubrication life is necessary.

Like their Silver-Lube cousins, Life-Lube units have a housing made from PBT thermoplastic polyester which is highly resistant to corrosion. When combined with Molded-Oil bearing inserts and nitrile rubber seals, this design ensures chemical resistance and long service life.

Furthermore, the housing material removes any risk of contamination from painted or coated surfaces and its smooth finish reduces the amount of dirt found on the housing and reduces washdown time.

Another important feature for the food and beverage industry is the flinger seal, which deflects high pressure water from cleaning that would otherwise damage the seal, and protects the Molded-Oil filled cavity.

All these things come together to make Life-Lube, like Silver-Lube and our stainless steel Deep Groove Ball Bearings, an ideal component for the Food and Beverage sector with its rigorous cleanliness and hygiene demands.

For more information on Bearing Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#NSK #ERIKS #LetsMakeIndustryWorkBetter #Bearings #FoodAndBeverage #DeepGrooveBallBearings #SilverLube #LifeLube